Products

-

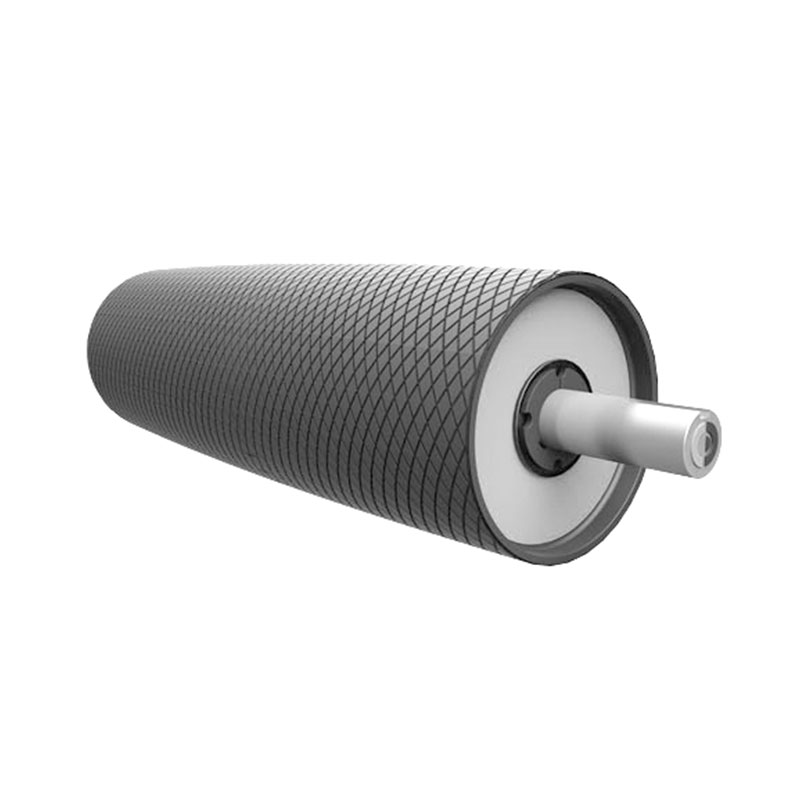

Polyurethane wear -resistant liner

-

Kolesiko leg

-

Polyurethane springs

-

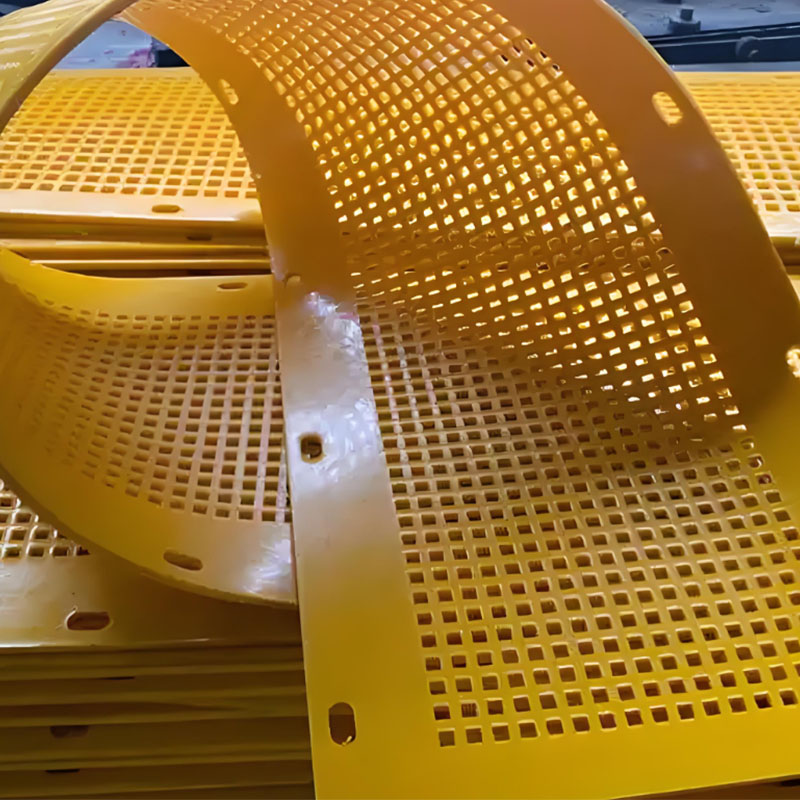

Sita for the roar of polyurethane

-

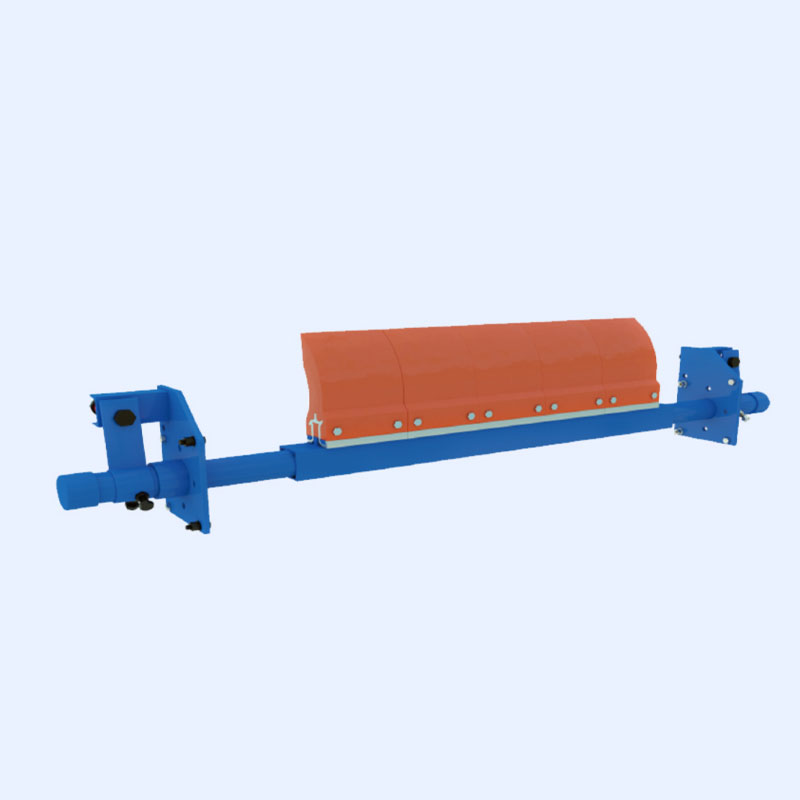

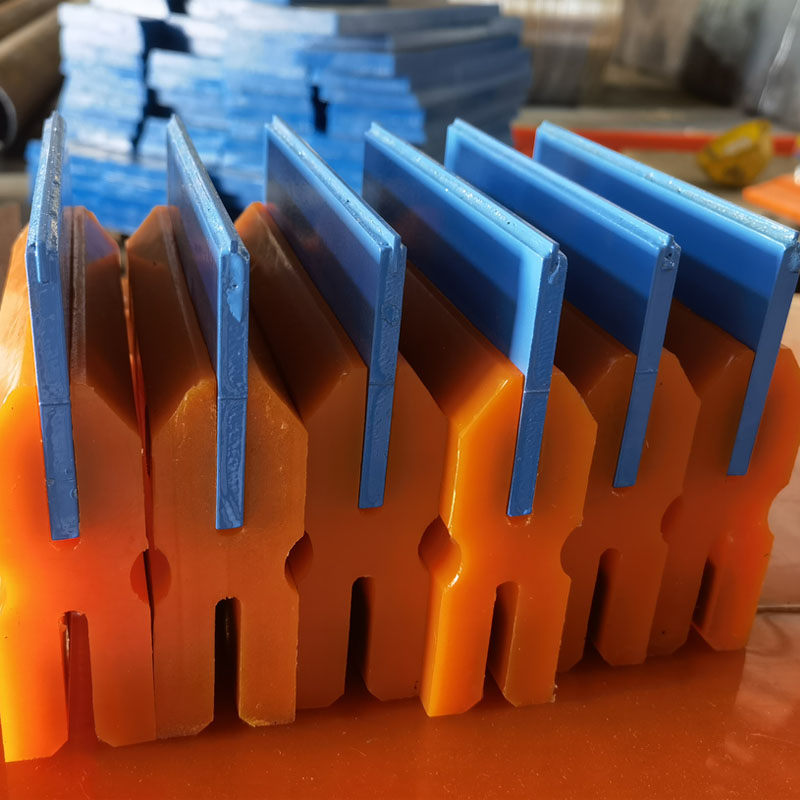

Polyurethane scraper

-

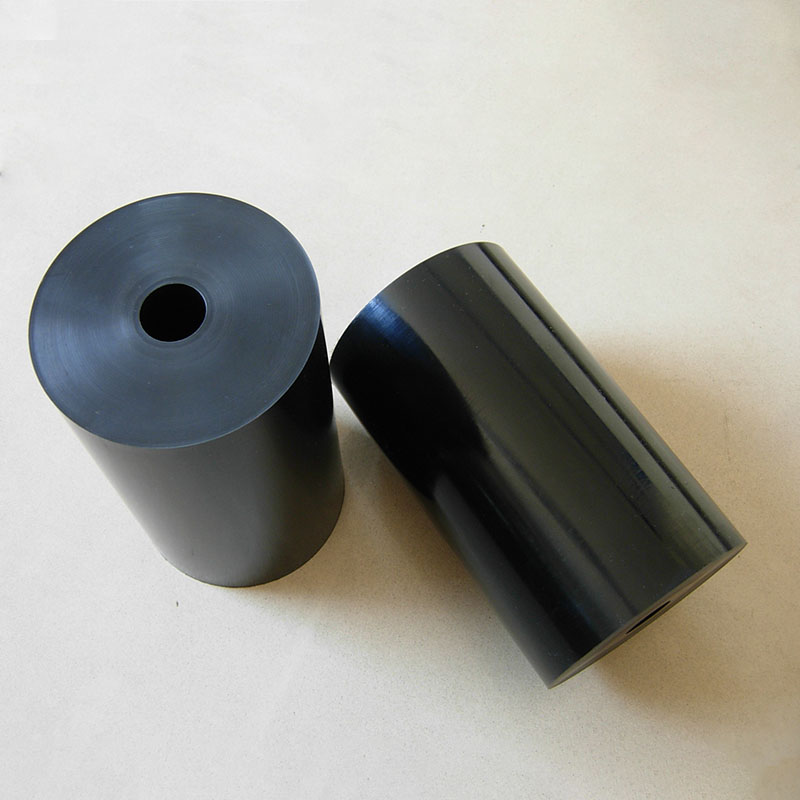

Polyurethane buffer

-

Assault seal

-

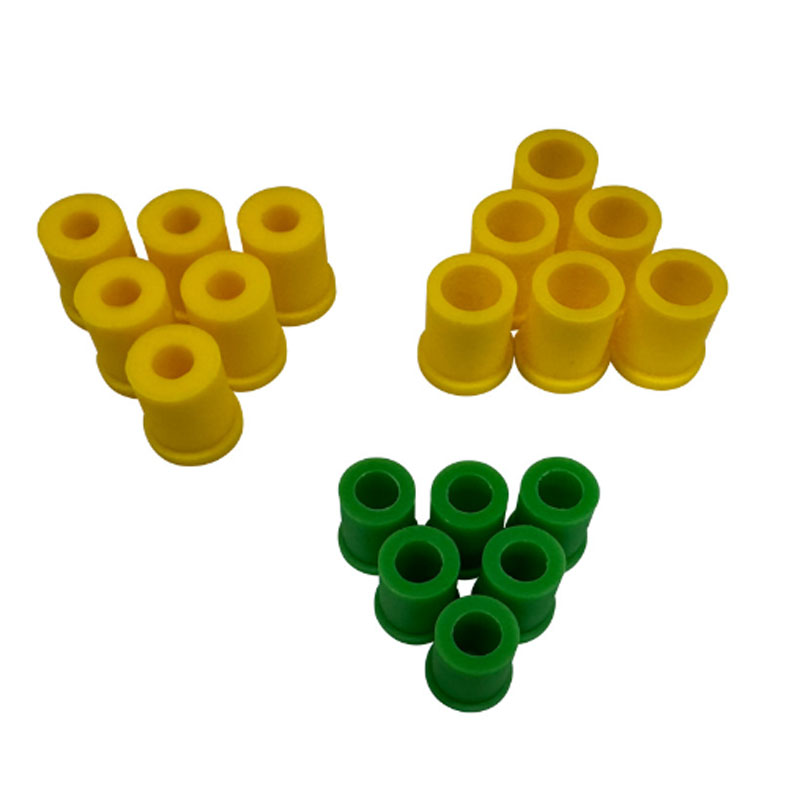

Rounds for attractions and fitness equipment

-

Sealing gasket

-

Bolt type of fastening

-

Polyurethane threaded videos

-

O-shaped seal

-

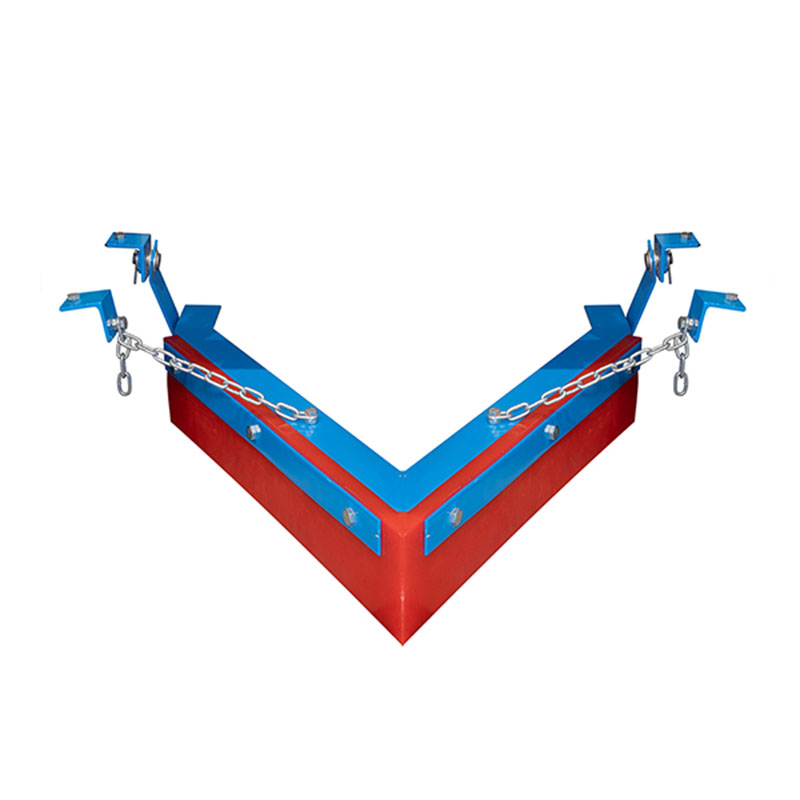

Polyurethane barrier from collisions

-

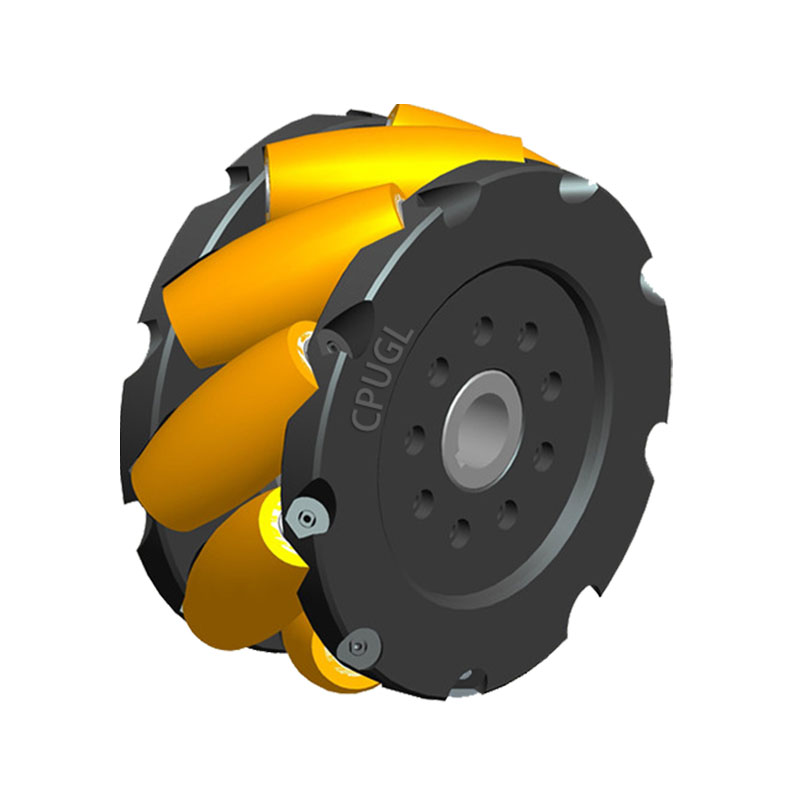

Wheels for robots

-

Sealing tape

-

Type of fastening of the flange

Y-shaped seal

When the Y-shaped seal is installed in the sealing groove, its two edges (i.e. two Y-shaped branches) under the influence of the medium pressure are deformed towards the sealing surface and tightly fit to it. This fit is due not only to the elasticity of the material is sealing ...

Description

marker

When the Y-shaped seal is installed in the sealing groove, its two edges (i.e. two Y-shaped branches) under the influence of the medium pressure are deformed towards the sealing surface and tightly fit to it. This fit is due not only to the elasticity of the material of the seal, but also by the thoughtful form of its cross section.

The Y-shaped seals can be divided into wide Y-shaped seals, narrow Y-shaped seals, YX-shaped seals, etc. In accordance with the different ratios of the part-time cross-sectional sides. Contenting the pressure of the wide part of the seal Y-type slightly less than that of the narrow type of y-type of seal, the y-type of seal, depending on whether the height of two lips is the same or not, can be divided into the shaft of the Y-type of seal, holes with unequal lips of the Y-type Y-type The seals and holes of the shaft are universal y-type seals with equal lips .y-shaped seals can also be divided into Y-shaped seals made of nitrile rubber, y-shaped seals made of fluorolastomer, Y-shaped seals made of polyurethane rubber, depending on the material from which they are made.