Products

-

The video of the conveyor tape

-

Y-shaped seal

-

Railway transport wheel

-

Sealing tape

-

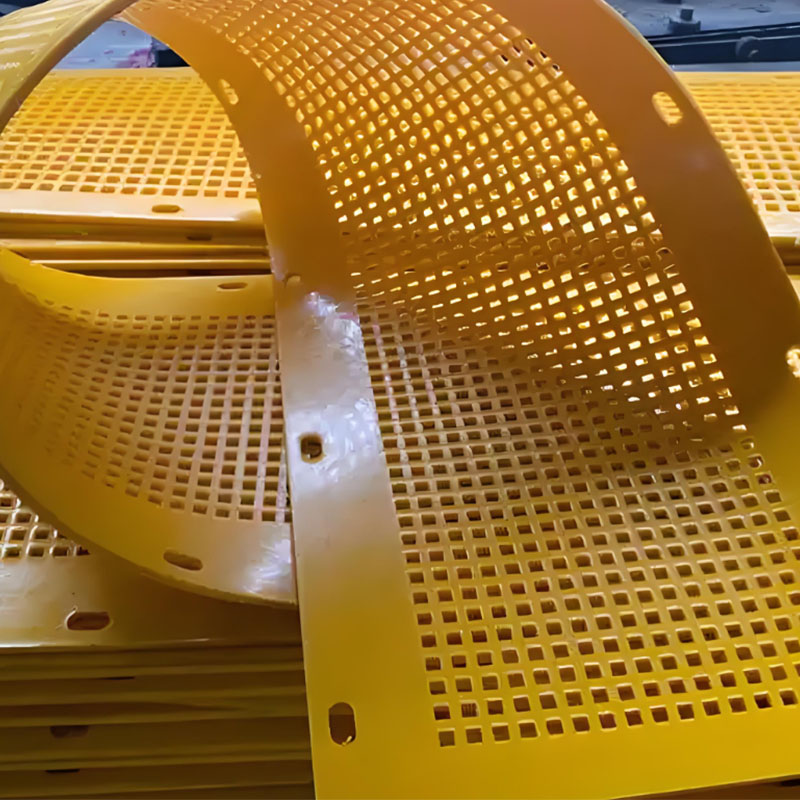

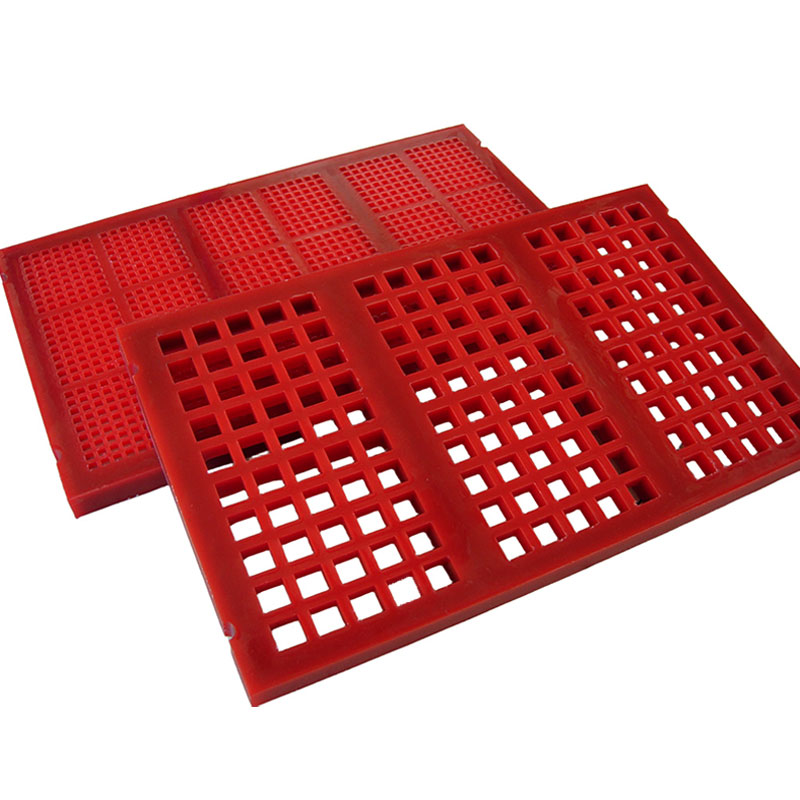

Sita for the roar of polyurethane

-

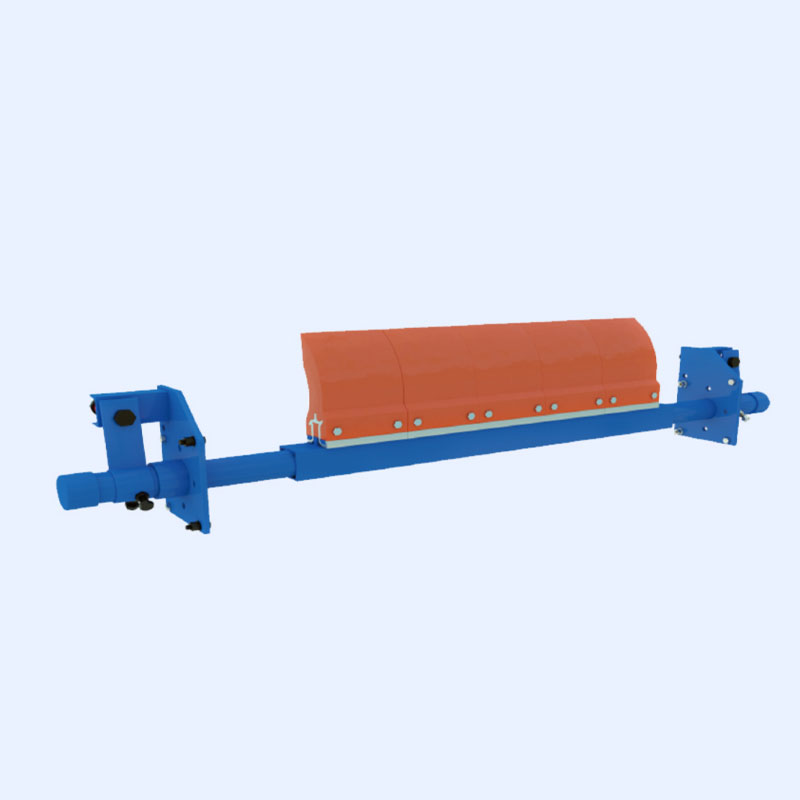

Polyurethane Otteral machine

-

Polyurethane threaded videos

-

Polyurethane lining pipes

-

Polyurethane sieve for roar

-

Polyurethane buffer

-

Type of fastening of the flange

-

Highlighting cover

-

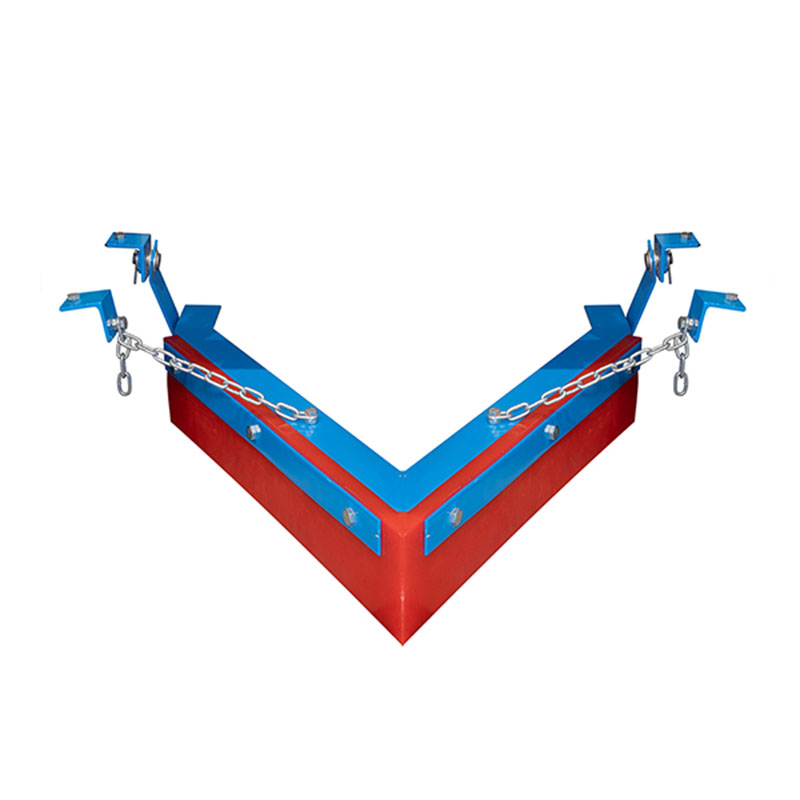

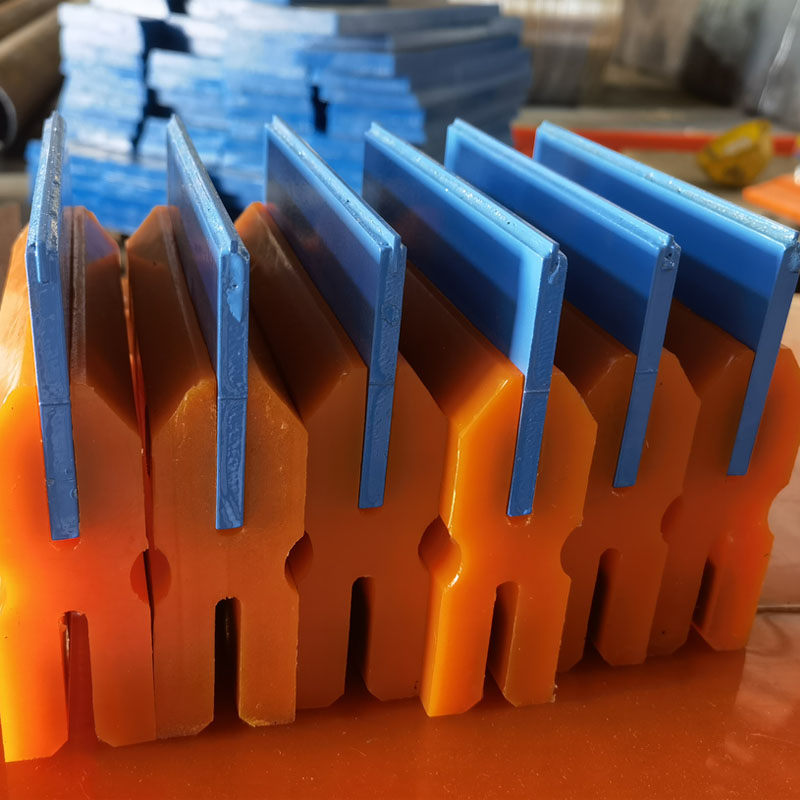

Polyurethane scraper

-

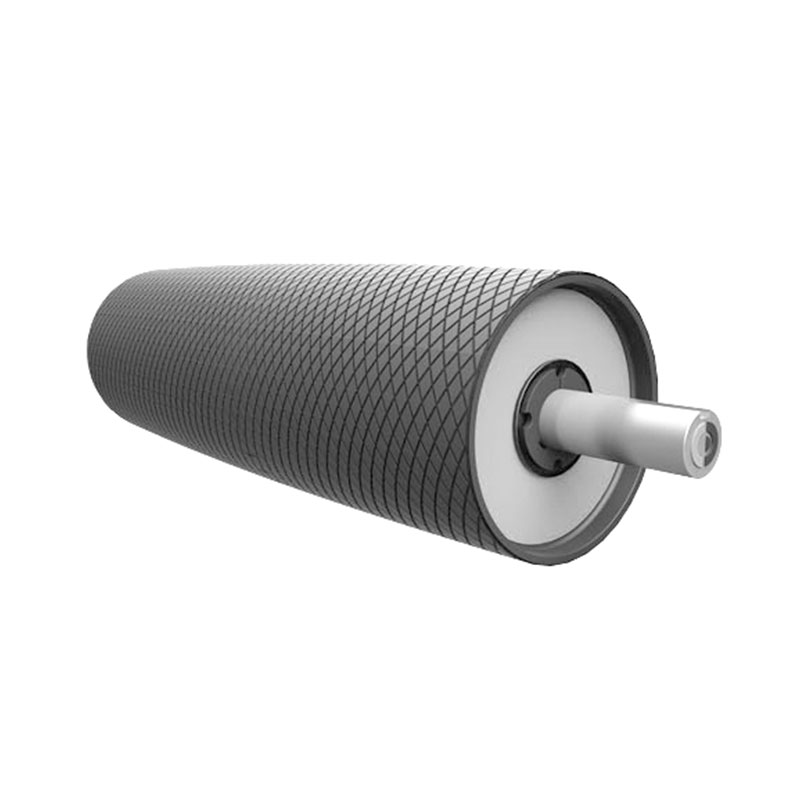

Polyurethane print shafts

-

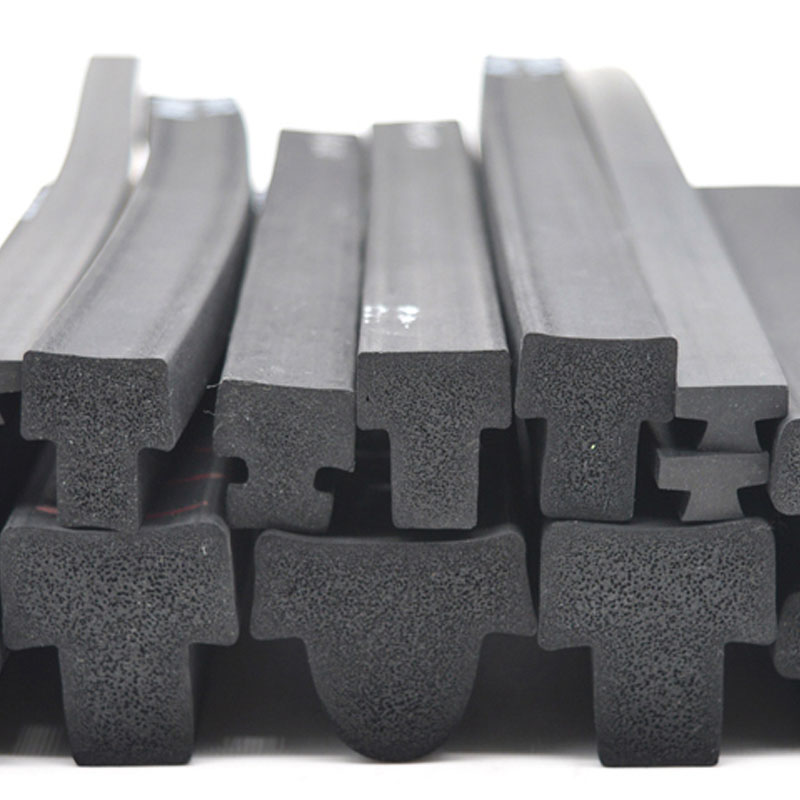

T-shaped seal

-

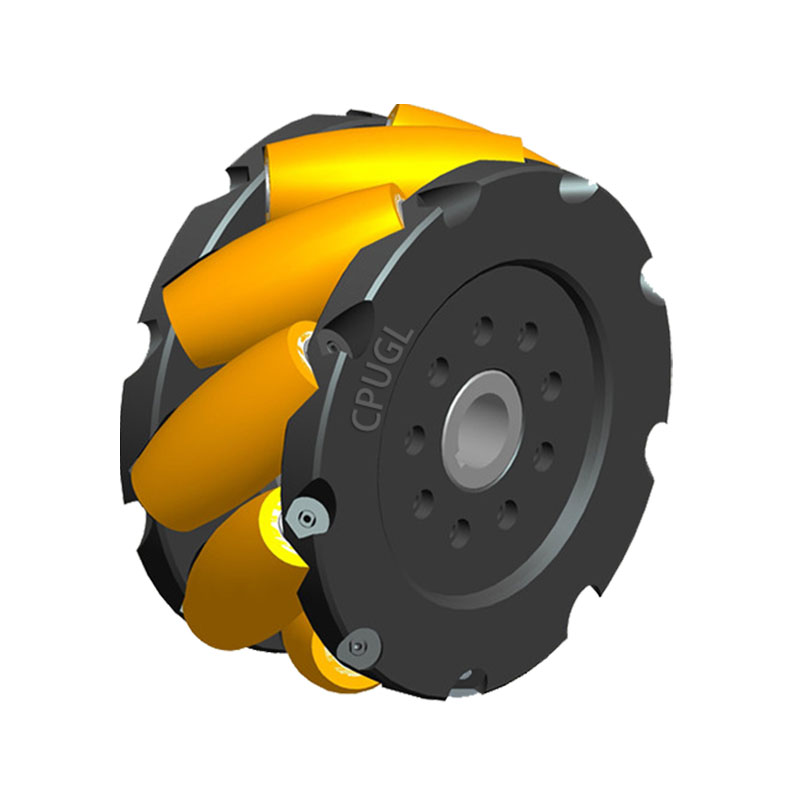

Wheels for robots

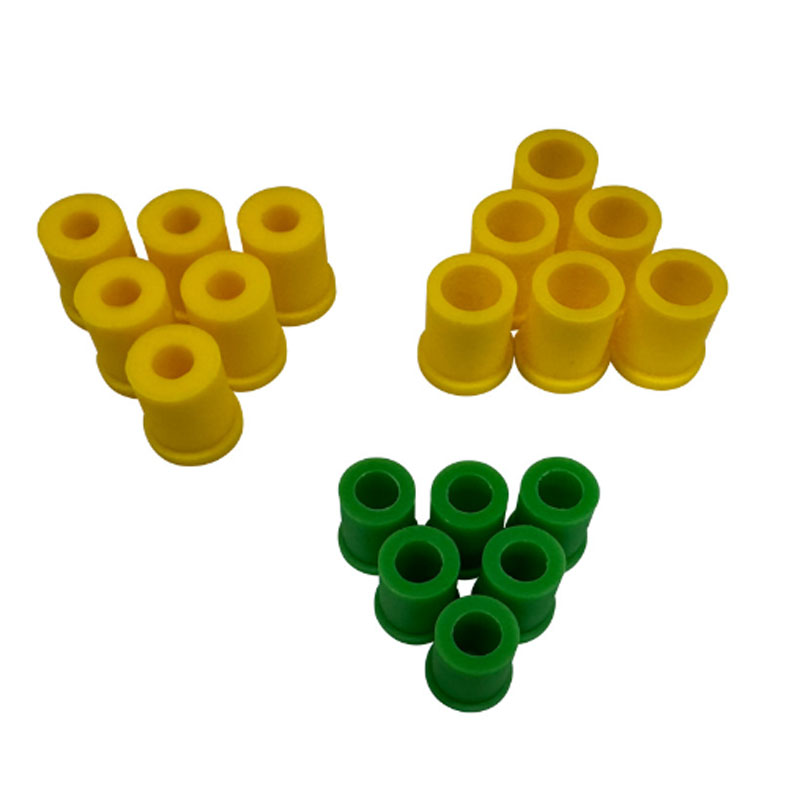

O-shaped seal

The sealing rings are classified depending on their purpose: they are divided into shaft seals, holes seals, dusty seals, guide rings, fixed seals and rotating seals; Classified according to the material: precision sealing rings on ...

Description

marker

The sealing rings are classified depending on their purpose: they are divided into shaft seals, holes seals, dusty seals, guide rings, fixed seals and rotating seals;

Classified by material:

Precision sealing rings to order are made according to samples, drawings and design requirements provided by customers.

Nitrilic rubber: oil -resistant, acid -resistant, alkalin, small deformation during compression.

Natural rubber: high strength for rupture, good characteristics of rupture, wear resistance, heat resistance, acid resistance, alchiiness.

Poftorcacus: high strength strength, good rupture productivity, low temperature -70 ℃ High temperature 300 ℃ Productivity unchanged, acid, alkali and oil resistance.

Silicone rubber: good elasticity, ozone resistance, resistance to aging, good characteristics for bending at low temperatures, a small set of compression, good electrical properties.

ethylenepropylene corneum : High strength for rupture, good characteristics of gap, resistance to abrasion, resistance to aging, resistance to ozone, good characteristics of bending at low temperatures, good electrical characteristics, resistance to acids and alkalis.