Polyurethane buffer springs: complete leadership

2025-03-28

This article provides comprehensive information aboutpolyurethane buffer springs, including their properties, application, advantages and disadvantages. We will consider various types of springs, factors affecting their choice, and provide practical advice on their use. Find out how to choose the rightPolyurethane buffer springsFor your needs.

What are polyurethane buffer springs?

Polyurethane buffer springs- These are elastic elements made of polyurethane, designed to extinguish blows and vibrations. They are an effective alternative to the traditional metal springs in a number of applications due to their high wear resistance, resistance to aggressive media and a wide range of rigidity. Polyurethane used in the production of these springs has excellent shock -absorbing properties that allow you to effectively absorb the energy of the impact and reduce the level of vibrations in mechanisms and systems.

Advantages of polyurethane buffer springs

Compared to metal analogues,Polyurethane buffer springshave a number of undeniable advantages:

- High wear resistance and durability;

- Resistance to chemicals, oils and solvents;

- Lack of corrosion;

- Wide range of stiffness and size;

- Good amortizing properties;

- Low noise during operation;

- Simplicity of installation and maintenance.

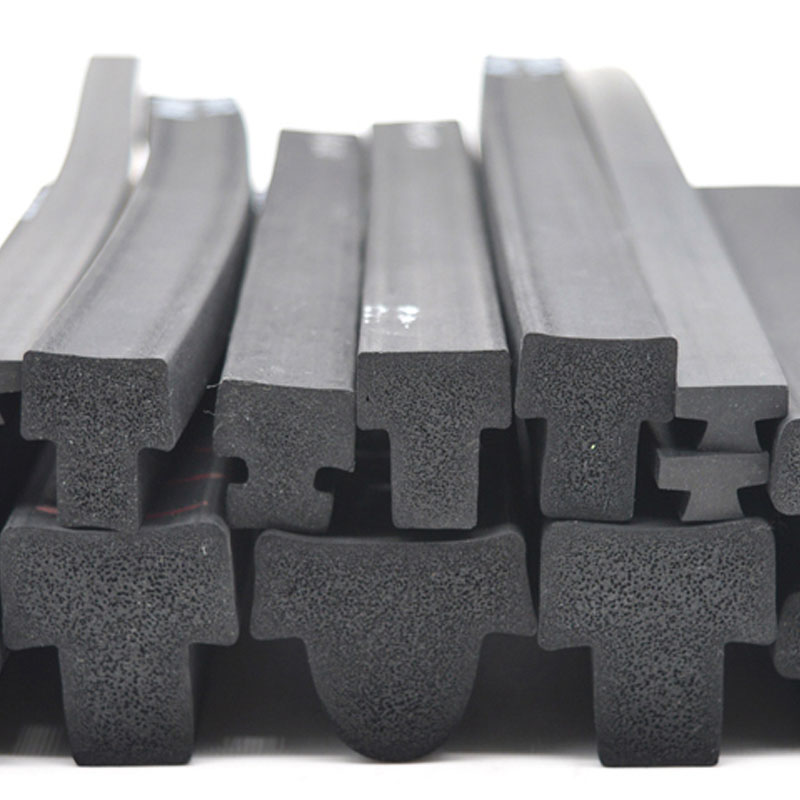

Types of polyurethane buffer springs

There are several typespolyurethane buffer springs, each of which is intended for specific applications. The most common include:

- Cylindrical springs;

- Cone -shaped springs;

- Springs with variable stiffness;

- Springs with integrated metal elements.

The choice of the type of spring depends on the specific requirements for stiffness, permissible deformation and operating conditions.

Use of polyurethane buffer springs

Polyurethane buffer springsWidely used in various industries:

- Mechanical engineering (damping of shocks in vehicles, industrial installations);

- Furniture industry (soft closing of doors and boxes);

- Construction (depreciation of vibrations in building structures);

- Production of medical equipment (reduction of vibrations and blows in medical equipment);

- Automotive (depreciation of strokes in the suspension, buffers to protect against damage).

The choice of polyurethane buffer springs

When choosingpolyurethane buffer springsThe following factors must be taken into account:

- Required rigidity;

- Permissible deformation;

- Operating conditions (temperature, humidity, exposure to chemicals);

- Overall dimensions;

- Load.

Table of comparison of the properties of various types of springs

| Characteristic | Polyurethane springs | Metal springs |

|---|---|---|

| Wear resistance | High | Average |

| Corrosion | Absent | Possible |

| Price | Average | It may be higher |

To obtain more information aboutpolyurethane buffer springsand their application, you can contact the company's specialistsOOOSHENYAN Xinyan Polyurethane Technologies. The company, founded in 2013, offers a wide range of high -qualitypolyurethane buffer springsmade using advanced technologies.

Please note that the choice of a specific type of spring and its parameters should be carried out taking into account the specifics of your application. It is necessary to consult a specialist to determine the optimal solution.