How to extend the service life of the rotary wheels?

2025-03-29

content

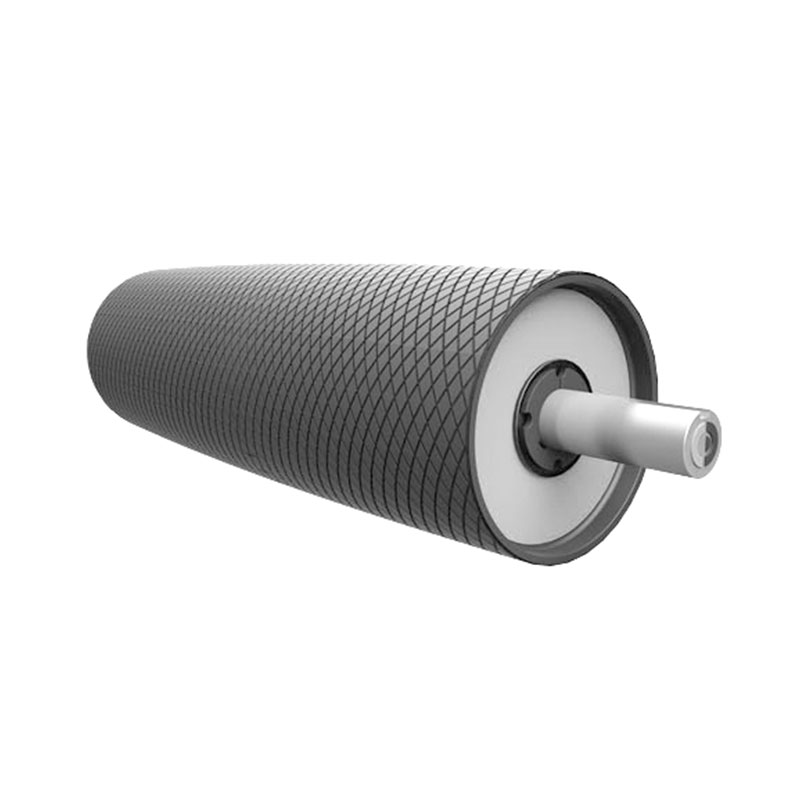

Rogue wheels are widely used in various industries and everyday life because of their universality and convenience. However, their durability depends on many factors, including operating conditions, the quality of materials and maintenance. To increase the service life of the rotary wheels, it is important to understand what precautions you need to take and how to properly care for them. This is especially true for those who use the wheel heavy polyurethane rotary, since these devices are often subjected to high loads and should be in perfect condition to ensure safety and efficiency.

The choice of suitable material

The correct choice of material of the wheel plays a key role in its durability. Polyurethane is one of the best materials for rotary wheels, as it has high resistance to wear, impacts and chemical reagents. This material is able to withstand heavy loads and is characterized by low noise during operation. When acquiring the wheel of heavy polyurethane rotary, pay attention to the quality of polyurethane, its thickness and density. Cheap analogues can quickly fail, without withstanding the declared characteristics.

Proper maintenance

Regular maintenance is one of the main factors affecting the service life of the rotary wheels. Inspect the wheels for cracks, deformations or other damage. Timely eliminate pollution that can get into the mechanism to avoid accelerated wear. It is also important to lubricate the rotary mechanism with a special lubricant to reduce friction and prevent corrosion. This is especially true for the wheels of heavy polyurethane rotary, used in difficult production conditions.

Accounting for operating conditions

Operation conditions directly affect the condition and durability of the rotary wheels. If you use wheels in aggressive environments, with a high content of chemical reagents or at extreme temperatures, check with the manufacturer how these conditions correspond to the characteristics of the wheels. The wheel heavy polyurethane rotary is especially advantageous in such conditions due to its unique properties, but even it needs proper care. Follow the loads and avoid exceeding the maximum permissible load on the wheel.

Professional installation

Professional installation is another significant aspect that affects the durability of the rotary wheels. If the installation is performed incorrectly, a violation of the balance may occur, which will lead to uneven wear and fast failure. Contact professionals for installing the wheels of heavy polyurethane rotary ones to be confident in their reliable and durable work. Proper setting up the rotary unit will provide smooth rotation and reduce the resistance during movement, which will also positively affect the service life.

Stress effect and movement speed

When using rotary wheels, it is important to take into account their permissible load and speed of movement. The overload can lead to rapid wear and damage to the wheels, while excessive speed creates additional pressure on the rotary mechanism. Regular verification and control over these parameters will help to avoid premature failure of the wheels. The hard -loaded polyurethane rotary wheel most often has a high ability to withstand significant loads, but the excess of these parameters can adversely affect its durability.

Using original spare parts

The use of original spare parts when repairing or replacing the elements of rotary wheels plays an important role in maintaining their performance. Fakes or low -quality analogues can significantly reduce the life of the wheels and lead to serious breakdowns. When buying spare parts for the wheel of heavy polyurethane rotary, make sure that they are certified and recommended by the manufacturer. This will ensure that all the technical characteristics and reliability in operation.

Thus, the key to the durability of the rotary wheels is an integrated approach, which includes the choice of quality material, regular maintenance, professional installation and accounting of operating conditions. Due to compliance with these simple recommendations, you can extend the service life of your wheels by minimizing the costs of their repair and replacement. More information can be found on the manufacturer’s website, for example, by visitingThe wheel heavy polyurethane rotary.