How do polyurethane wheels affect the ecology?

2025-02-01

Introduction

In the modern world, where more and more attention is paid to environmental stability, the choice of materials for production plays a key role. Polyurethane wheels are becoming more and more popular due to their unique properties and wide use. Although it seems that their impact on the environment is minimal, there are many factors that must be taken into account. In this article, we study as polyurethane wheels, in particularUnwell polyurethane wheels, affect the ecology and what can be done to reduce the possible negative impact, while ensuring comfort and durability of use.

Production process and its impact

The process of production of polyurethane wheels is associated using chemical compounds that can be potentially dangerous to the environment. Their main components are isocyanates and polio that respond to the formation of polyurethane. These substances can cause air and water pollution if they are not processed and properly disposed of. In addition, production requires significant energy resources, which in turn leads to greenhouse gas emissions.

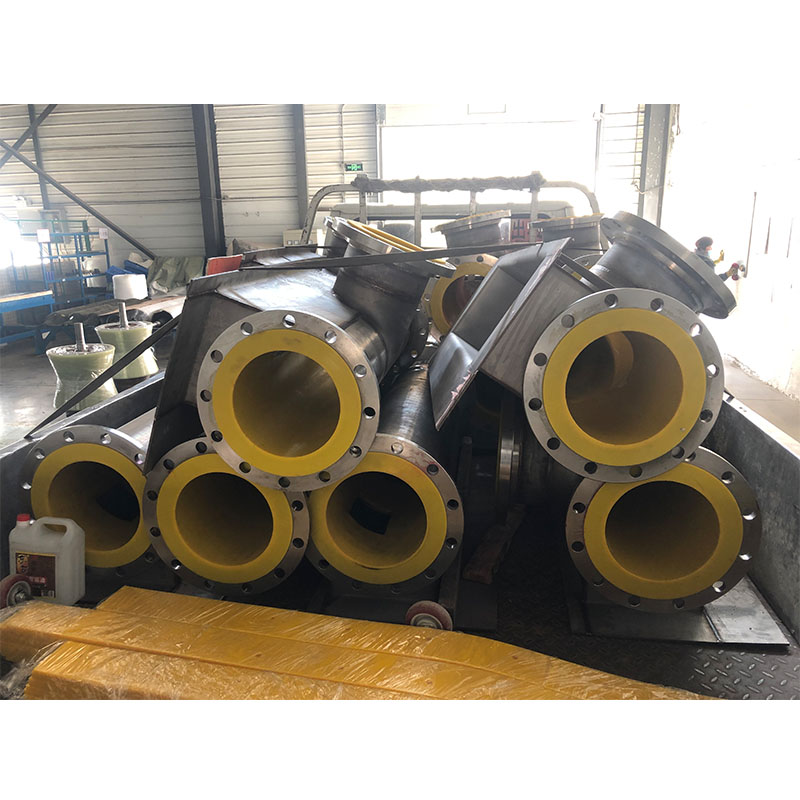

Nevertheless, the development of technology actively helps to reduce these negative factors. Modern methods include more economical use of resources and the introduction of safe waste disposal technologies. The use of recyclables and alternative energy sources also becomes an important part of environmentally responsible production. For companies, such as our company from Shannyan, this is an important step in creating environmentally friendly products, such asUnwell polyurethane wheels.

Service life and durability

One of the main advantages of polyurethane wheels is their amazing durability. Compared to rubber analogues, they demonstrate better resistance to wear and exposure to aggressive environments. This allows you to significantly extend the service life of such products, which leads to a decrease in the total number of produced and disposed wheels. In turn, this reduces pressure on the ecological system and reduces the number of emissions from waste processing.

Polyurethane stability makes it an ideal choice for use in conditions where wear, chemical exposure or extreme temperature boundaries can quickly destroy more traditional materials. An increase in durability also helps to reduce the costs of maintenance and replacement, which makes them more economically profitable, despite the initially higher cost. Guided by these advantages,Unwell polyurethane wheelsThey become the best choice for many applications, from warehouse carts to industrial equipment.

Disposal and secondary processing

One of the most important stages in the cycle of the life of polyurethane wheels is disposal. It is not enough just to throw out their wheels out of the landfill: it is necessary to develop effective methods for their processing. Traditional polyurethane products, as a rule, are difficult to do and can accumulate in the environment for many years, if they are not disposed of properly.

Modern innovations are aimed at developing new methods of recycling polyurethane, which allow us to extract useful components from them and re -use to create new products. Companies are increasingly introducing closed production cycles that minimize waste. In this context, the integration of environmentally stable principles in the design and productionUnwell polyurethane wheelsIt becomes an obligatory direction for reducing their ecological trace.

Environmental advantages of non -use of cameras

Unwell polyurethane wheelsThey have a number of advantages over their chamber analogues. First of all, their design and material can reduce the negative impact on the ecology. The absence of a camera reduces the amount of necessary materials, which in turn reduces the total costs of resources related to production and disposal.

In addition, a lower amount of materials means a smaller mass, which leads to improved characteristics of vehicles in terms of fuel saving and reduces greenhouse gas emissions. These wheels also provide the best characteristics of tightness and strength, which reduces the risk of leaks and subsequent environmental pollution. As a result, useUnwell polyurethane wheelsIt helps to reduce the environmental load due to the reduction of production and operational emissions.

Influence on human health and safety

Health and safety are important aspects of environmentally friendly practices. Production enterprises working with polyurethane products are required to protect their employees and the environment from possible effects of toxic substances. The chemical components of polyurethane, although stable in finished products, can cause fears at the stages of production and processing.

To minimize risks, it is strategically important to integrate the processes of controlling pollution, safe disposal and elimination of chemical emissions. In addition, end users benefit from useUnwell polyurethane wheels: Reducing noise, less dynamic effects and improved clutch indicators make them safer for use in a wide range of conditions, from production enterprises to street vehicles.

Conclusion

Polyurethane wheels have a significant impact on the natural environment, and this influence can be both positive and negative. With the help of new technologies and a more responsible approach to production, their potential harm can be minimized, while the maximum use of the advantages of durability and sustainability helps to build a more stable future. In this context, the role of not only manufacturers, but also end users who choose environmentally friendly solutions, such asUnwell polyurethane wheelsavailable for detailed familiarization on the website of our partners.