Select and use of stretch sites (sieve grid with tension)

2025-03-28

content

This article provides comprehensive information about the selection and use of stretch systems, including various types, materials, tension methods and areas of application. You will learn how to choose the rightSita grid with tensionFor your specific tasks, as well as receive practical tips for installation and operation.

Types of stretch systems and their characteristics

Materials forSita mesh with tension

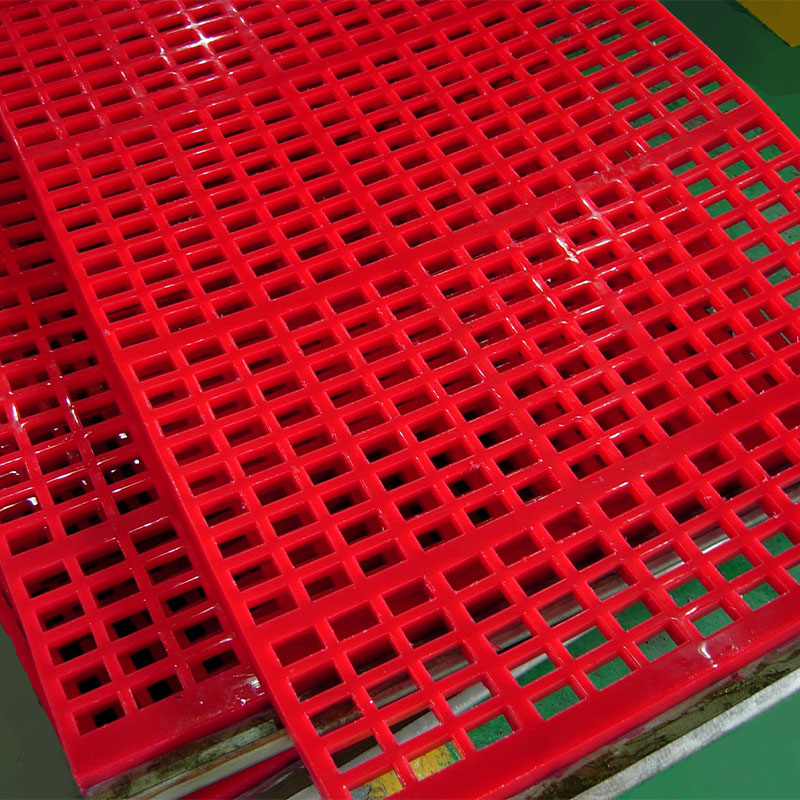

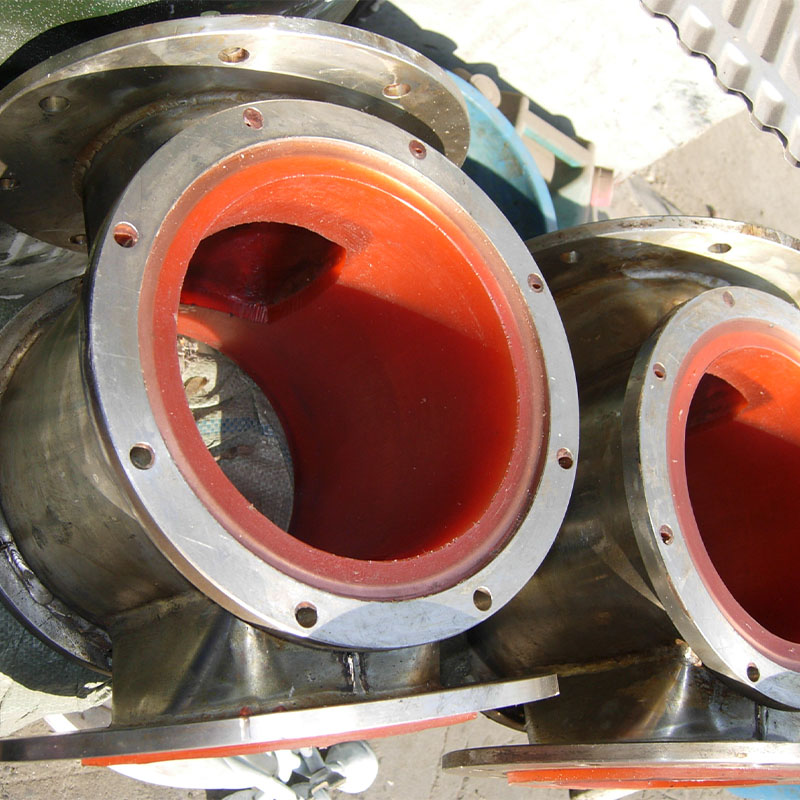

Stretch sieves are made of various materials, each of which has its own advantages and disadvantages. The most common materials include stainless steel, polyester, nylon and other polymeric materials. Stainless steel provides high strength and durability, but can be more expensive. Polymeric materials, such as polyester and nylon, are more affordable in price and have good resistance to corrosion, but their strength can be lower than that of stainless steel. The choice of material depends on specific requirements for strength, chemical resistance and cost.

Various designs of stretch sieves

There are various designs of stretch sits that are optimized for various applications. For example, Sita with flat tension is suitable for filtering liquids with low viscosity, while sieves with wedge -shaped tension are more effective for filtering viscous materials. There are also sieves with different sizes of cells, which allows you to choose the best option for specific particles.

Tension methodsSita mesh with tension

The correct tension of the sieve is a critical factor for ensuring its effectiveness and durability. There are several tension methods, including mechanical tension using special clamps, hydraulic tension and tension with vacuum. The choice of the method depends on the size and type of sieve, as well as on the required level of tension.

Areas of the use of stretch sieves

Stretch sieves are widely used in various industries, including food, chemical, pharmaceutical and mining. They are used to filter liquids, separation of solid particles, as well as for other processes that require accurate filtration. For example, in the food industry, stretch sieves are used to filter juices and other drinks, in the chemical industry - to separate various chemical compounds. The right choiceSita mesh with tensionCritically important to achieve the required result in each specific application.

How to choose a suitable tension sieve?

The choice of a suitable stretch sieve depends on a number of factors, including the size and type of particles that must be filtered, fluid viscosity, chemical properties of the processed materials, as well as budget restrictions. Before choosing, it is necessary to carefully analyze all these factors in order to ensure the optimal performance and durability of the sieve.

Care and maintenance of stretch sieves

Regular care and maintenance of tension sites are necessary to ensure their durability and efficient work. This includes the regular cleaning of the sieve from pollution, verification for damage and timely replacement of worn sieves. Incorrect care can lead to a decrease in the effectiveness of filtration and damage to the sieve.

Comparison of various types of tension sit

| Characteristic | Stainless steel | Polyester |

|---|---|---|

| Strength | High | Average |

| Price | High | Low |

| Corrosion resistance | High | Good |

To obtain additional information aboutSita mesh with tensionand other products, please visitSite LLC Signyan Polyurethane Technologies. Our company, founded in 2013, specializes in the production and supply of high -quality materials for filtering.