Reducer pulley is driven

Reducer pulley: inconspicuous, but important assistant

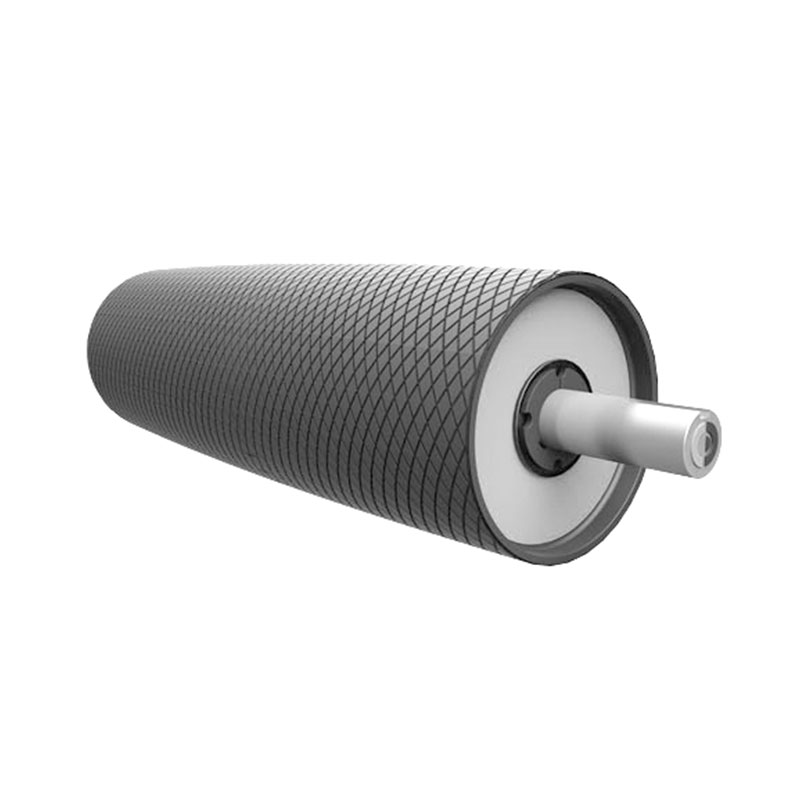

The driven pulley pulley is, in fact, the wheel that rotates, transmitting power from the leading pulley. It is like an inconspicuous, but very important assistant in mechanisms where the transmission of rotational movement and speed adjustment is needed. Imagine a system where you need to translate a quick rotation into a slow, and effort to increase. The driven pulley is a key element of this system. He assumes energy from the engine and transfers it, but with the required speed and power.

Design and purpose

The driven pulley is often made of durable metal, like its leading brother. Its diameter, as well as the number of teeth or grooves for the belt (depending on the type of drive) determines how quickly and strongly it can transmit rotation. The larger the diameter, the slower the rotation, and the greater the gear force, the greater the power. It is important that the pulley is well balanced, otherwise vibrations and damage to the mechanism may occur. It is also important that the material and design of the pulley comply with the requirements for the load and the rotational moment. The design should be reliable and durable.

Materials and their meaning

The choice of material for the driven pulley plays a key role. Usually these are steel, aluminum alloys, or other durable materials. Steel provides high strength, which is important at high loads. Aluminum alloys, albeit less durable, are easier and more economical. It is important to consider that when choosing the material, it is necessary to take into account not only strength, but also resistance to wear, corrosion and other influences that may occur during operation. For example, in aggressive environments, such as high humidity or the presence of chemicals, materials with increased resistance to corrosion are needed.

Selection and maintenance

When choosing a driven pulley, it is necessary to take into account the features of the reducer used and the required transmission parameters. If the parameters are not taken into account, then the pulley may not cope with the task. An incorrectly selected pulley can lead to a premature failure of the entire mechanism. Proper maintenance is the key to long and uninterrupted work. Regular verification for wear, cracks, and other damage, timely lubrication are important elements of prevention. This will avoid unexpected breakdowns and extend the service life of the gearbox.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

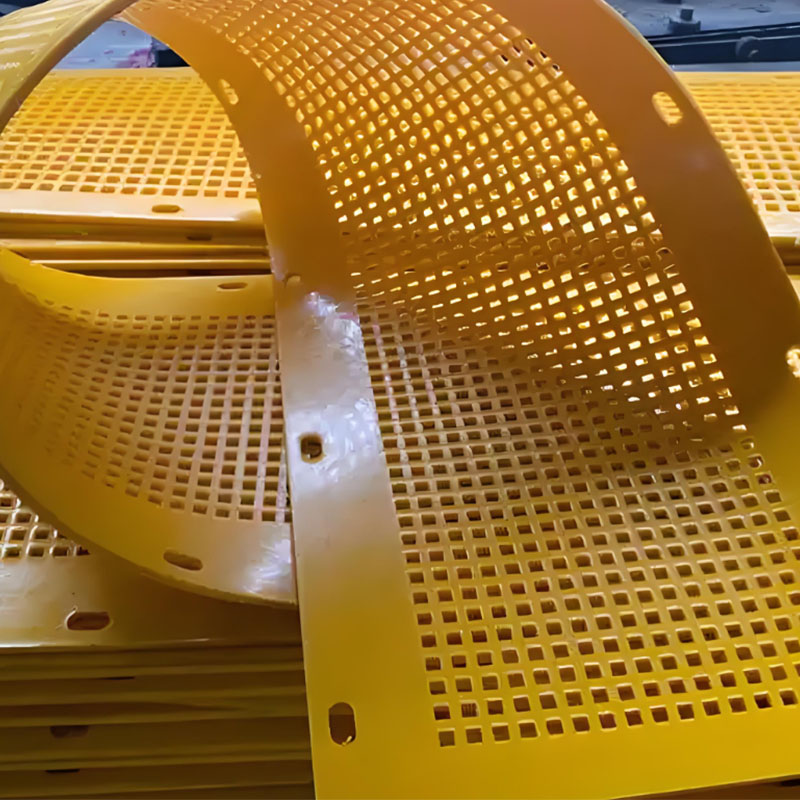

Related search- Chinese suppliers of polyurethane sieves for roar

- China Polyurethane Wheel Factory 200 mm

- Chinese main buyers of gaskets of heating elements

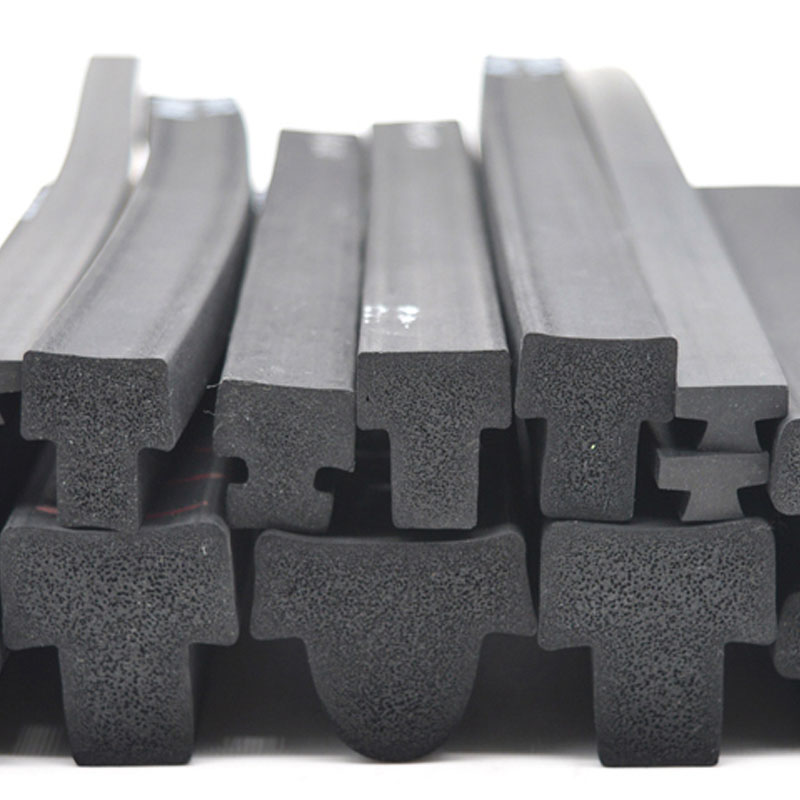

- Ten sealing in China

- Rubber Wheel Supplier

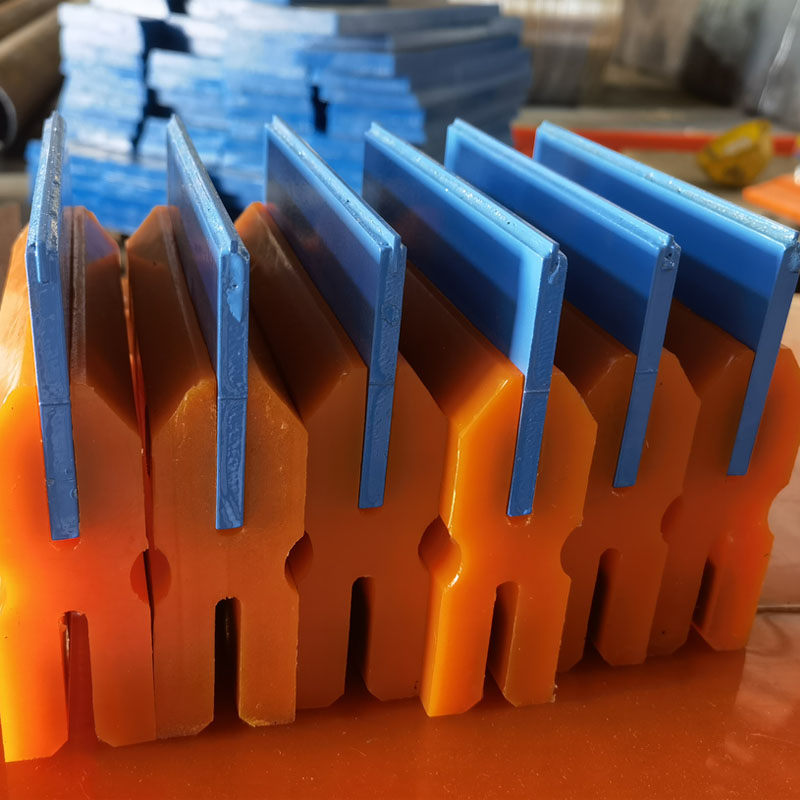

- Polyurethane anti -suggestion block manufacturer

- Conveyor bearing rollers

- conveyor strip is secondary

- Polyurethane sieve plate in bulk

- Chinese manufacturers of Reynolds spring gaskets