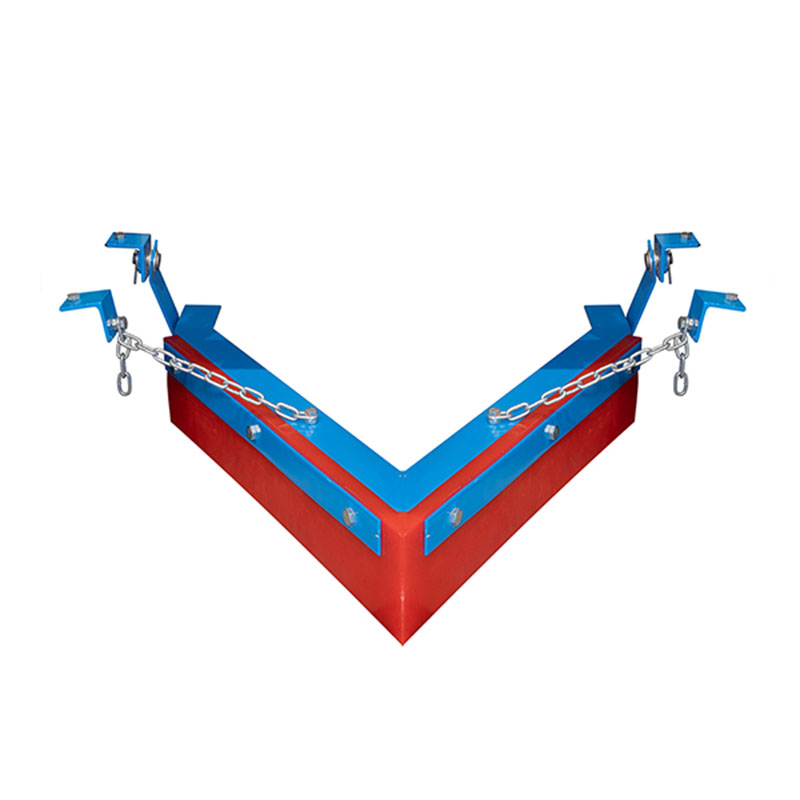

The pulley of the driven Neva

The pulley of the led Neva

The leading pulley is an important detail in the mechanisms, especially in systems where the transmission of rotational movement from one shaft to another is required. Imagine that you twist the pen, and from it the movement is transmitted, for example, to the pump that shakes water. In this process, the pulleys of Neva plays a key role, like an intermediary who intercepts the energy of rotation and transfers it further.

The principle of operation of the pulley of the led Neva

The work of the ledger is based on the principle of friction. The stretched belt attached to the leading pulley transfers rotational movement to the driven. The driven pulley, being attached? To the belt, forced to rotate synchronously with the host. It is important that the speed of rotation of the driven pulley will depend on the diameter of the leading and driven pulleys. The greater the difference in diameters, the different the speed of rotation will be. So, if the leading pulley is larger, then the led will rotate more slowly, and vice versa. Neva is most likely a trademark or the name of the manufacturer of such a pulley.

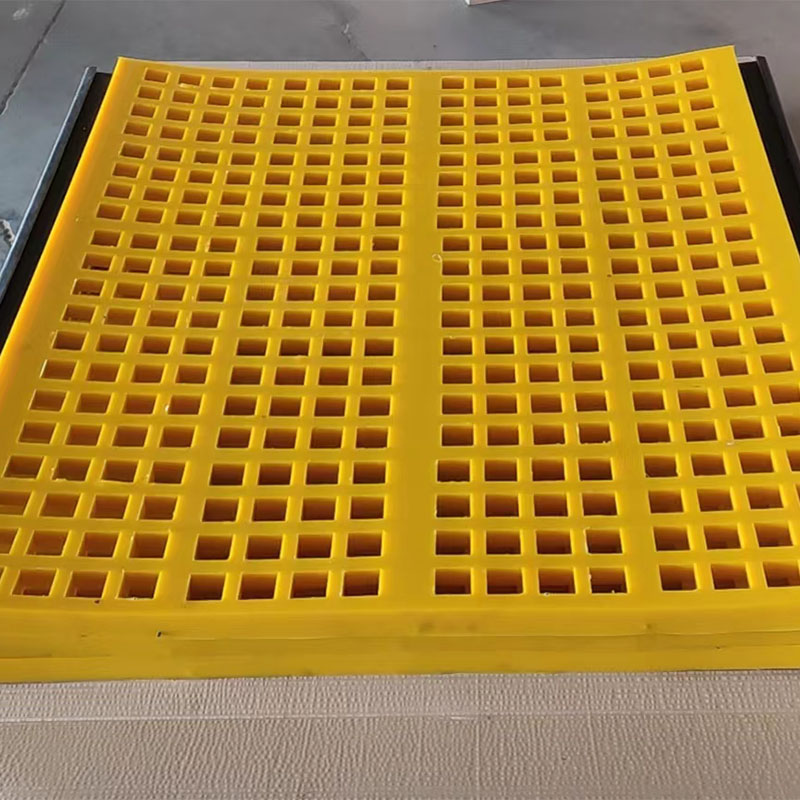

Features of the pulleys of the led Neva

The pulleys of the led Neva, like any others, are made from various materials, such as metal, plastic. The choice of material depends on operating conditions. To work in aggressive environments (for example, with chemically active substances), materials more resistant to exposure can be used. Strength and durability are also important, because the pulley should withstand significant loads without breakdowns. In addition, it is important that the belt tightly fit the pulley, without backlash and gaps, which will avoid energy losses and provide smooth, stable rotation.

The choice of pulley of the led Neva

When choosing the pulley of the led Neva, several factors must be taken into account. First of all, it is important to choose a pulley with the desired diameter in order to provide the required rotation speed. You also need to pay attention to the material of manufacture so that the pulley corresponds to the operating conditions. An additional factor is its strength, which guarantees long and uninterrupted operation of the mechanism. It is important to check the compatibility of the pulley with the belt to avoid damage. And, of course, you should turn to the technical characteristics and recommendations of the pulley manufacturer.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Leading customers of tension screens in China

- China Walking Tractor of the Label of the Factory

- Cleaner of the conveyor tape from the alloy in China

- Grits of sealing prp 30 mm in bulk

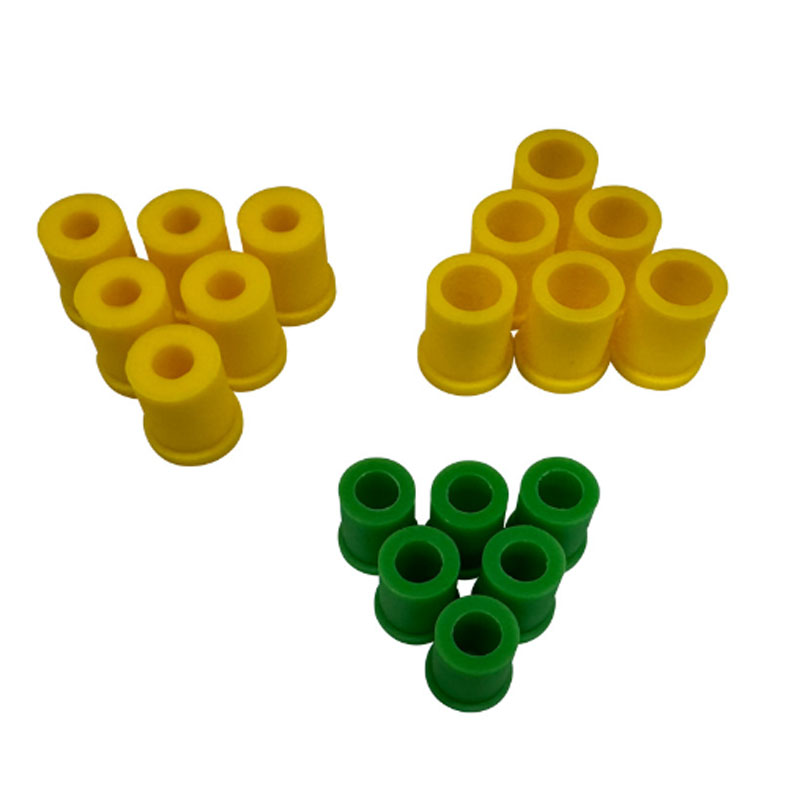

- spacers under the Niva springs

- Manufacturers sealing gasket 1 1 4 in China

- Prices for Niva Front spring washers in China

- Manufacturers of conveyor tapes from alloy in China

- Polyurethane buffer springs plant

- Prices for polyurethane printing videos in China