Products

-

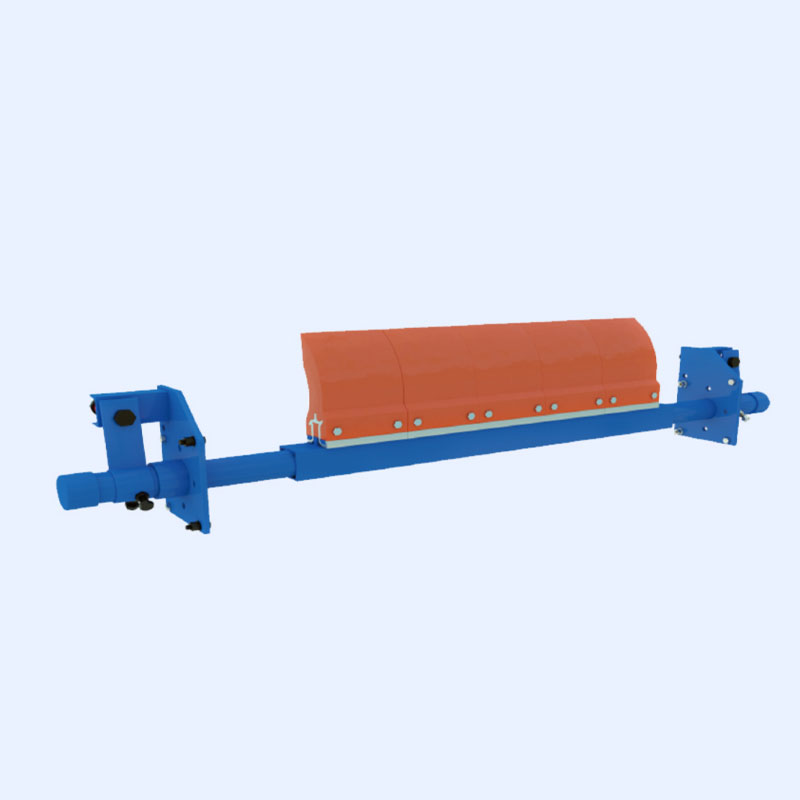

Polyurethane scraper

-

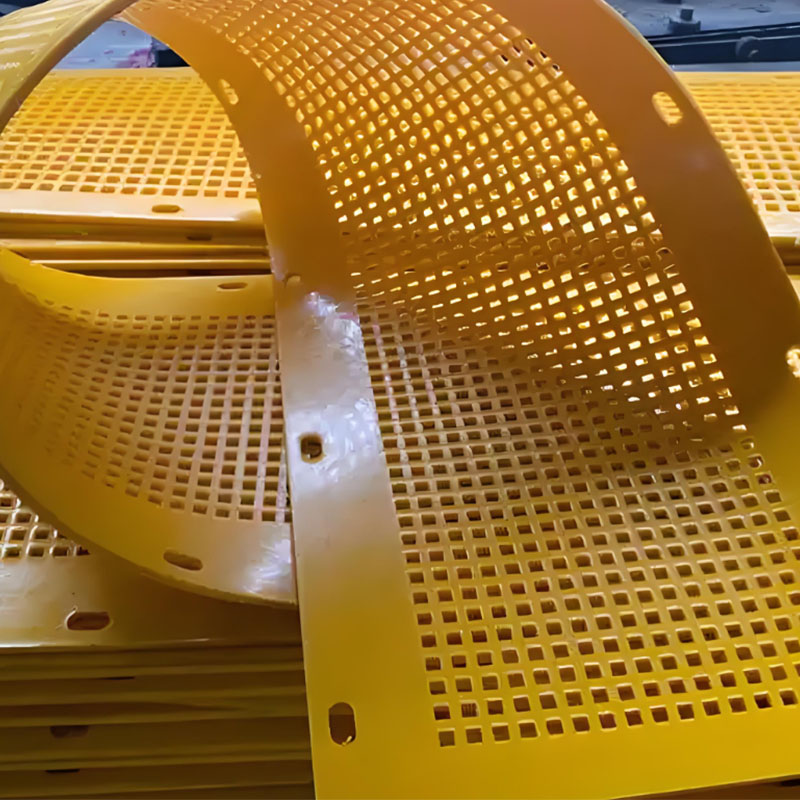

Drum screen

-

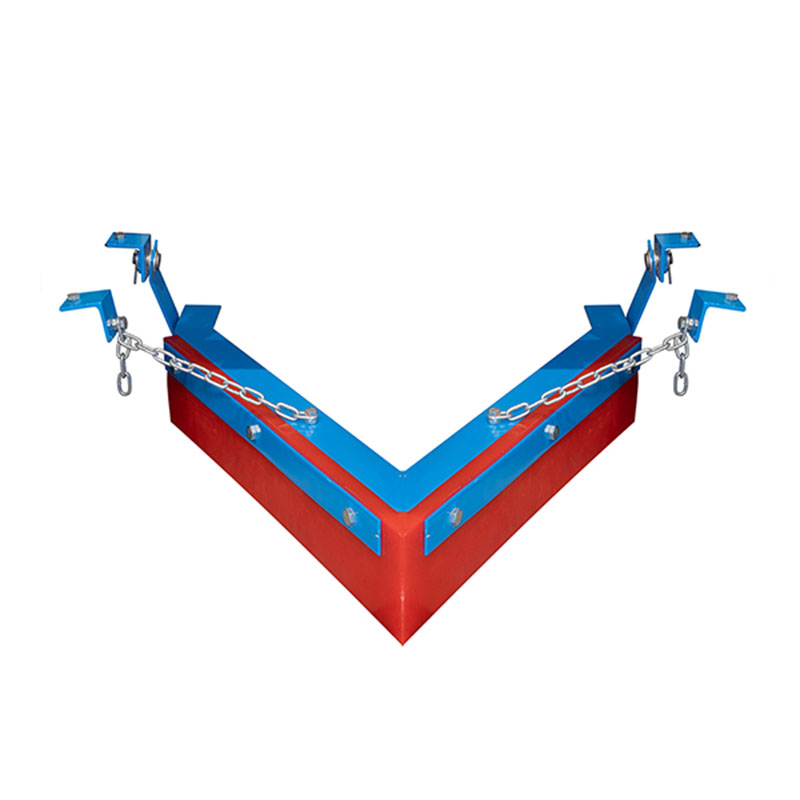

Y-shaped seal

-

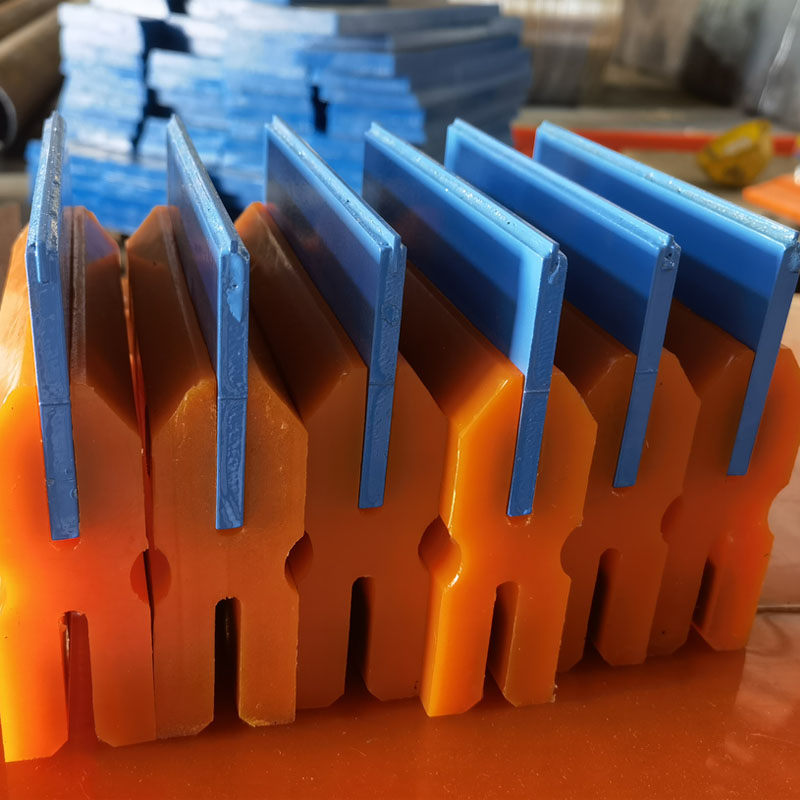

Polyurethane threaded videos

-

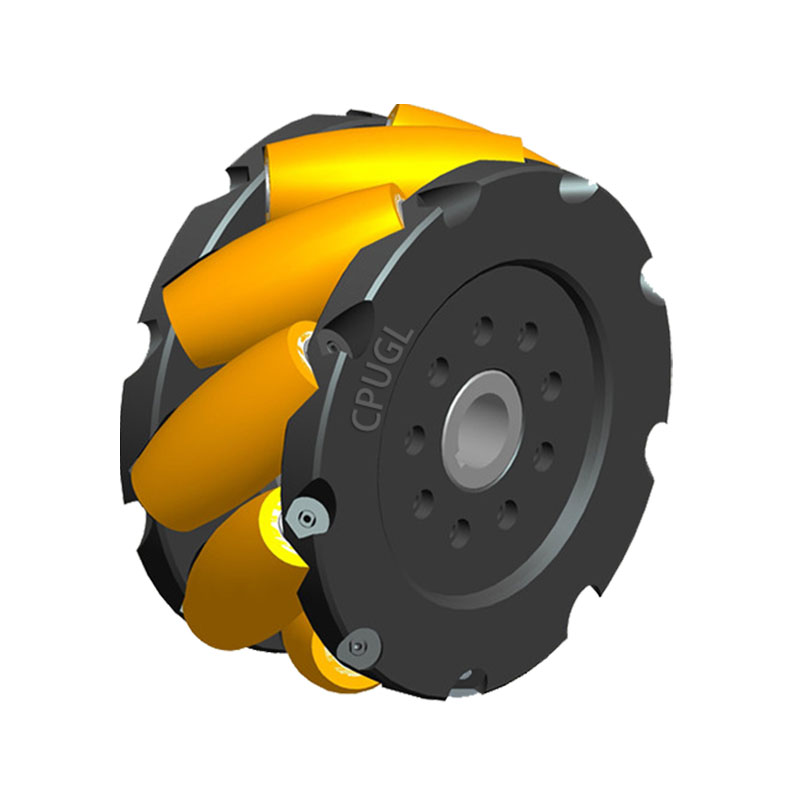

Mekanum Wheels

-

Sealing tape

-

The video of the conveyor tape

-

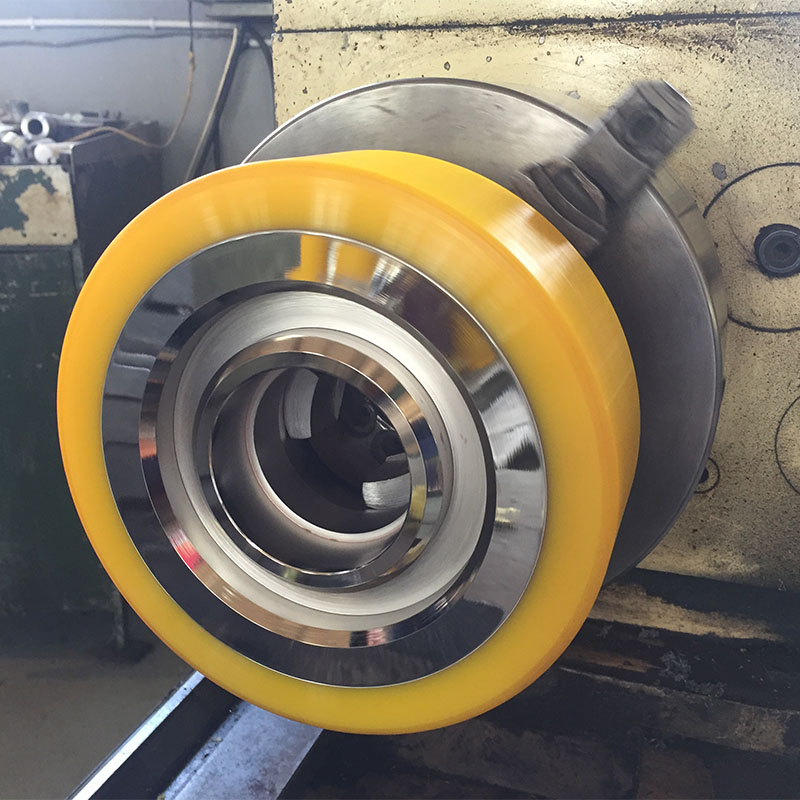

Heavy wheel

-

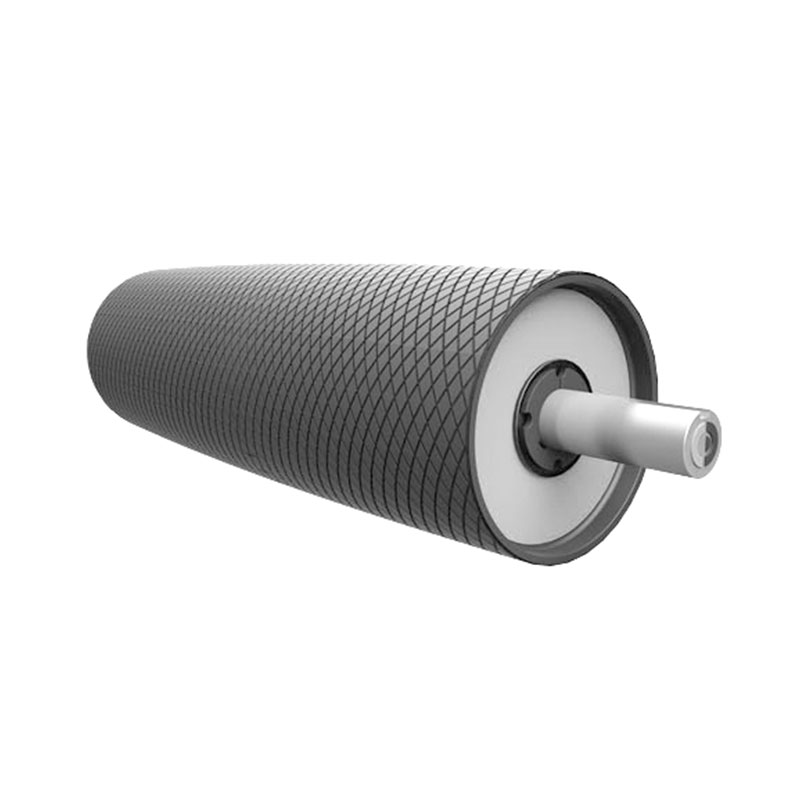

Polyurethane print shafts

-

Polyurethane V-shaped video

-

Wheels for robots

-

Polyurethane lining pipes

-

O-shaped seal

-

The rod is wicker mesh

-

Bolt type of fastening

-

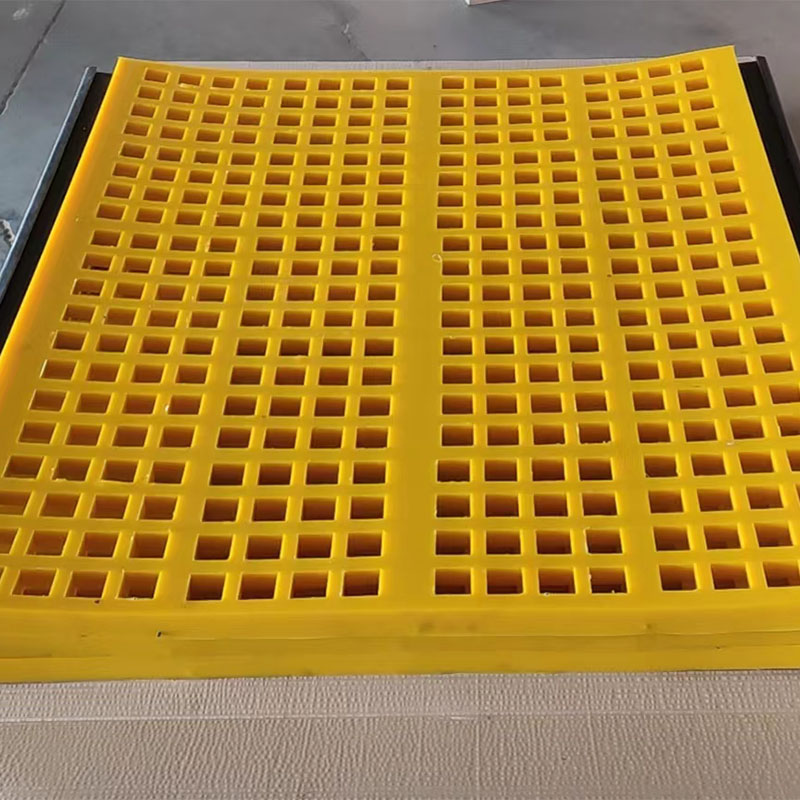

Sita for the roar of polyurethane

Sealing ring

The elasticity of the sealing ring allows you to create a certain pressure between it and the sealing surface, thus forming a sealing interface. In practice, adjusting the thickness of the sealing ring, the shape of the cross section and other parameters, you can achieve different with ...

Description

marker

The elasticity of the sealing ring allows you to create a certain pressure between it and the sealing surface, thus forming a sealing interface. In practice, regulating the thickness of the sealing ring, the transverse section and other parameters, you can achieve various degrees of compression deformation for adaptation to various compaction requirements.

Firstly, a POLLETARAN RUSSIAN RIGHT RING Pu: the mechanical properties of polyurethane rubber are very good, abrasion resistance, high pressure resistance is much better than that of other rubber. Resistance to aging, ozone resistance, oil resistance is also quite good, but high temperature is easily hydrolyzed.

Secondly, a nitril-based nitrile tire ring: suitable for an oil-based hydraulic oil, glycol-based hydraulic oil, two-epir lubricants, gasoline, water, silicone lubricant, silicone oil and other media. It is the most widely used, the lowest cost of rubber seals.

Sil -tires sealing ring SIL: it has excellent resistance to heat, cold, ozone and atmospheric aging. They have good insulating properties. But the strength of the gap is worse than that of ordinary rubber, and does not have oil resistance. Fourth, Viton fluent of the fluorine: high heat resistance is better than silicone rubber, excellent weather resistance, ozone resistance and chemical resistance, cold resistance is low.

FLS fluorinated rubber ring: its performance has the advantages of fluorine -containing rubber and silicone rubber, oil resistance, resistance to solvents, stability to fuel oil, high and low heat resistance.

Six, EPDM EPDM rubber sealing ring: has very good weather resistance, ozone resistance, water resistance and chemical resistance.