Products

-

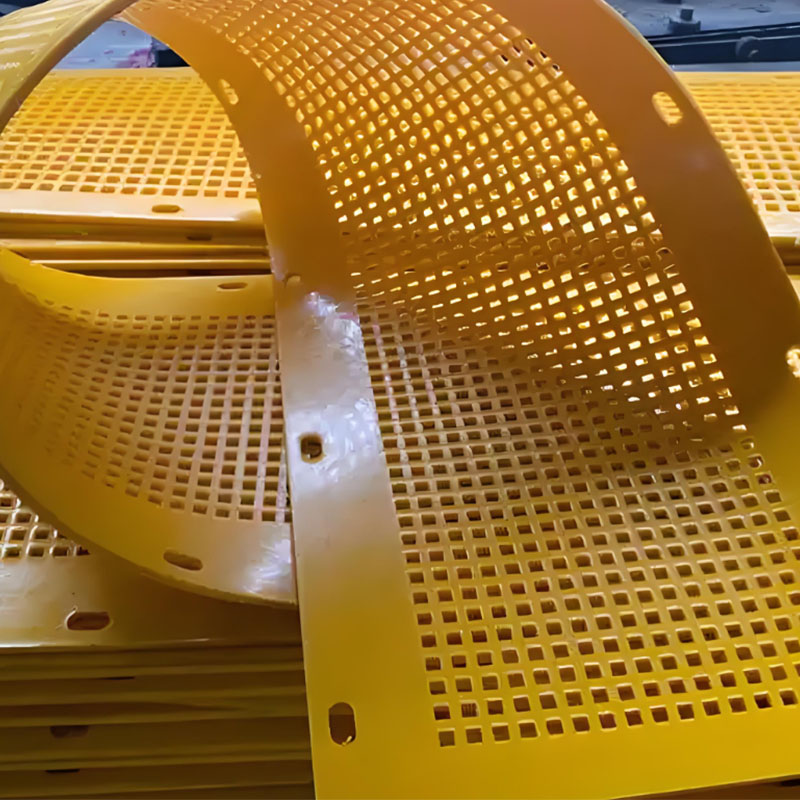

Type of fastening of the flange

-

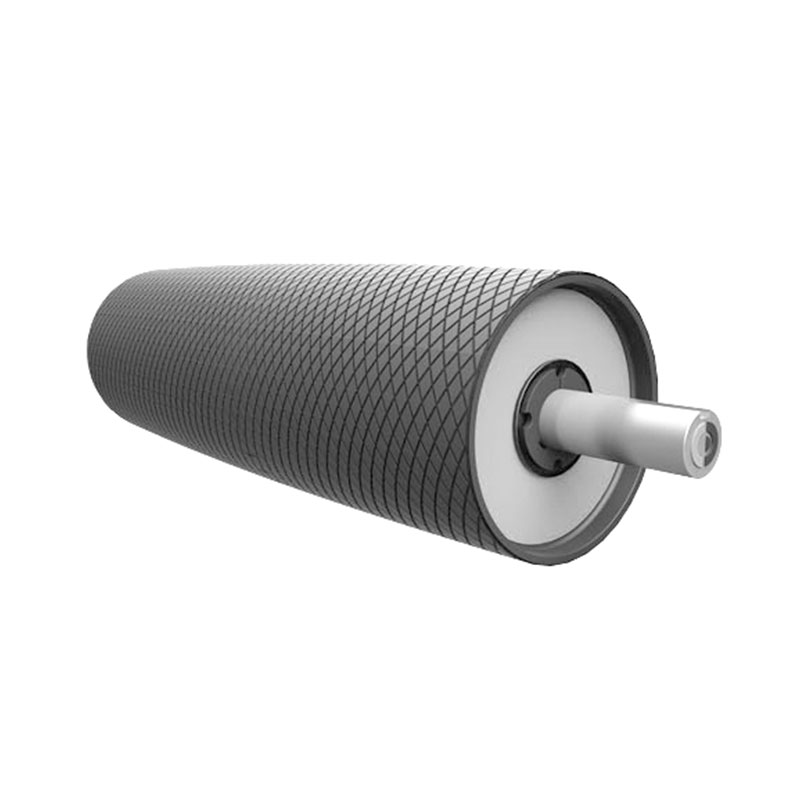

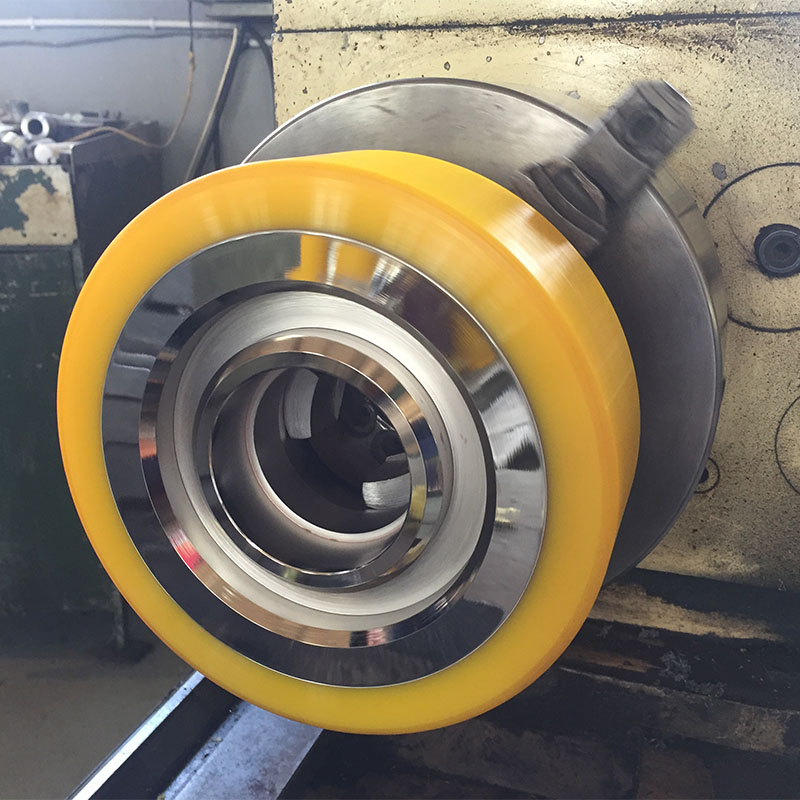

Polyurethane roller

-

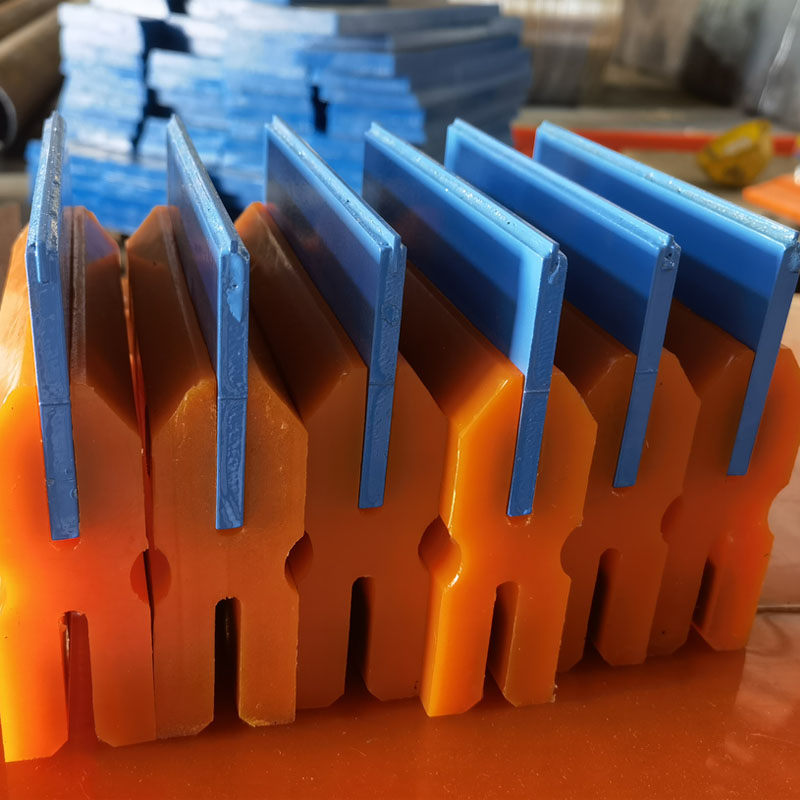

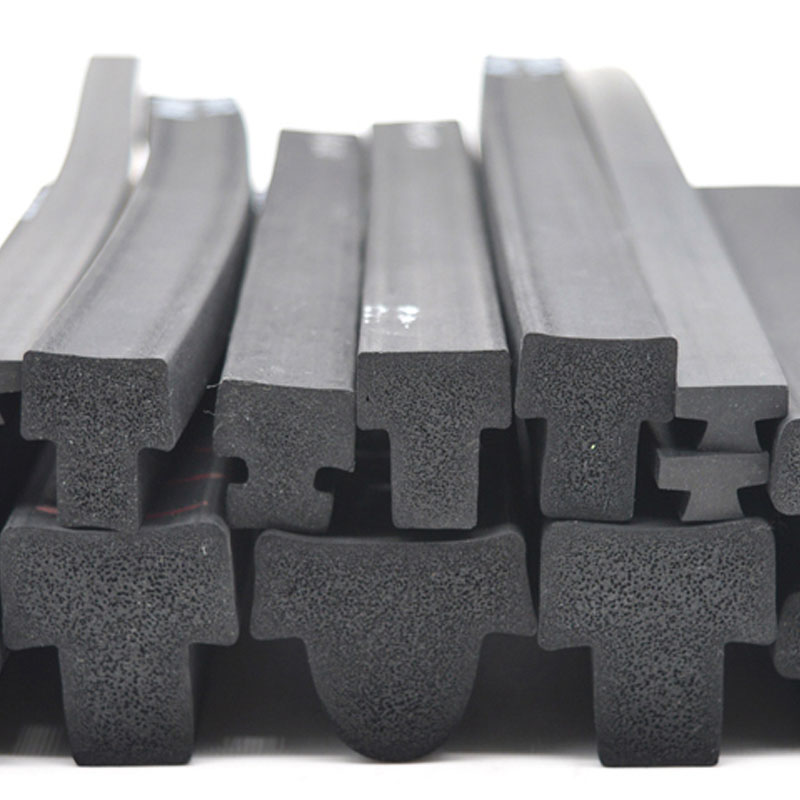

Polyurethane vibration gaskets

-

Polyurethane print shafts

-

Polyurethane shaped details

-

Polyurethane barrier from collisions

-

U-shaped seal

-

Wheels for robots

-

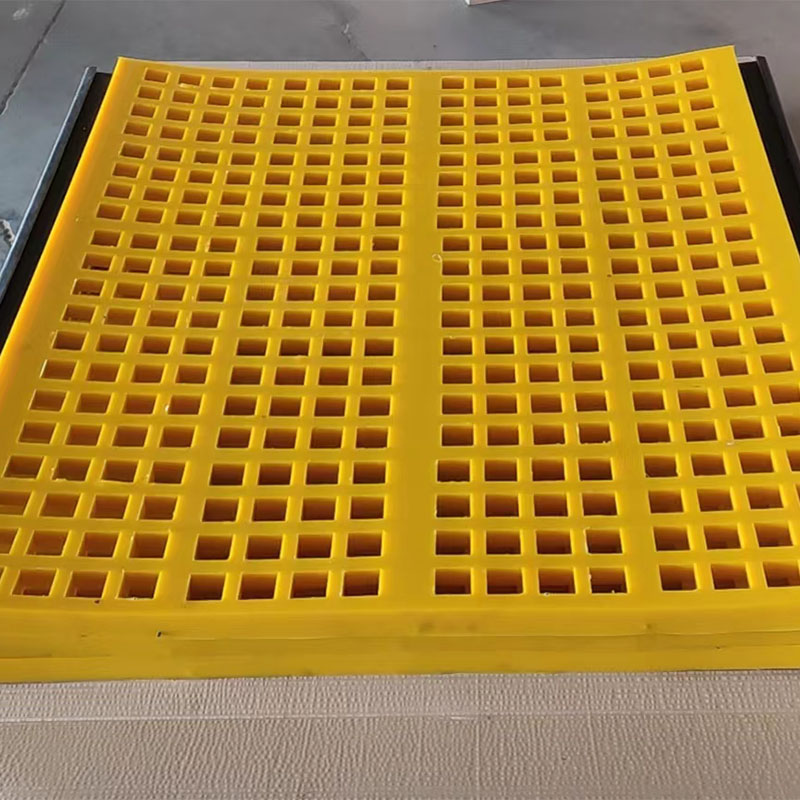

The rod is wicker mesh

-

Wheels for robots

-

Sita mesh with tension

-

Heavy wheel

-

T-shaped seal

-

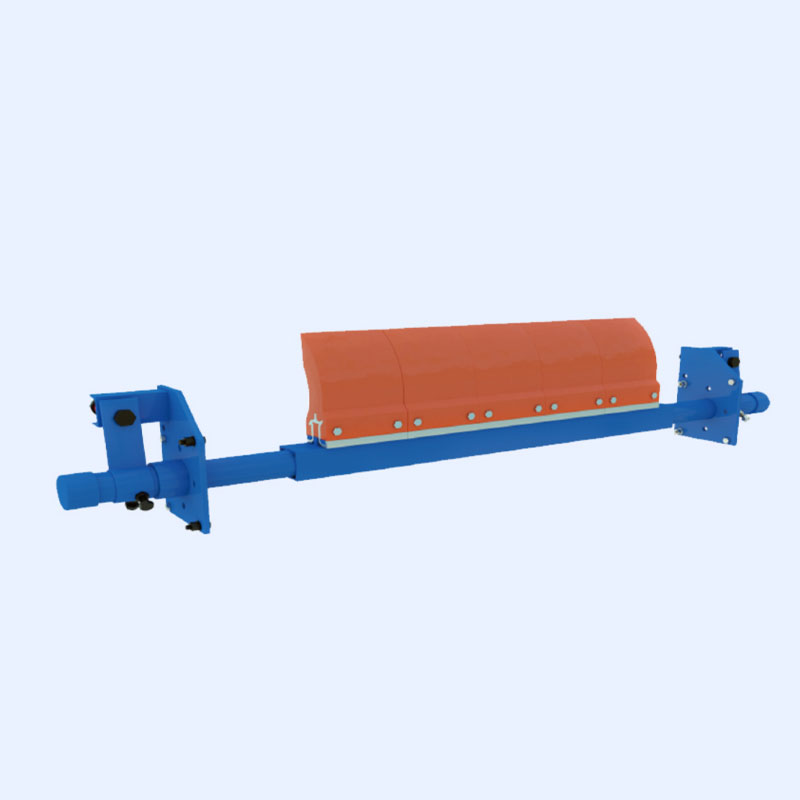

The video of the conveyor tape

-

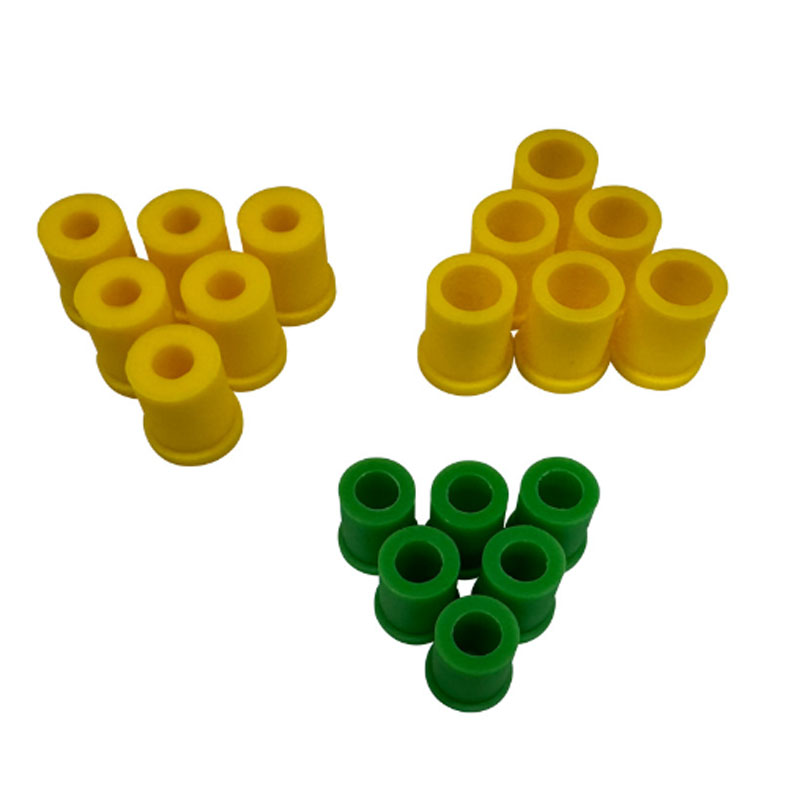

A sealed plug

-

Sealing ring

Highlighting cover

Sealing covers can be made in accordance with various conditions and compaction requirements. During use, it plays the role of insulation of the external environment and internal devices, and also prevents the leakage of liquid and gas. Polyurethane sealing materials widely sprout ...

Description

marker

Sealing covers can be made in accordance with various conditions and compaction requirements. During use, it plays the role of insulation of the external environment and internal devices, and also prevents the leakage of liquid and gas.

Polyurethane sealing materials are widely used in various seals, mainly due to their unique properties:

High wear resistance: the wear resistance of polyurethane is several times higher than that of rubber, and even exceeds the wear resistance of metal materials under certain extreme working conditions.

Good elasticity: polyurethane material has excellent elasticity, can quickly recover to its original state after exposure to external forces, maintaining tightness.

High strength and rigidity: polyurethane materials have high strength and impact strength, suitable for high loads and frequent movements.

Resistance to the effects of oil and chemicals: polyurethane has good resistance to oil, aliphatic hydrocarbons, salted water, etc., does not corrode and does not dissolve.

Adjustable hardness: adjusting the ratio of isocyanate and polyol, you can get polyurethane materials with different hardness for various areas of application.

Resistance to low temperatures: polyurethane materials can remain good elasticity and flexibility at low temperatures and do not become fragile.

Good anti -aging characteristics: polyurethane materials have good anti -aging characteristics in the conditions of exposure to ultraviolet rays and ozone.