Products

-

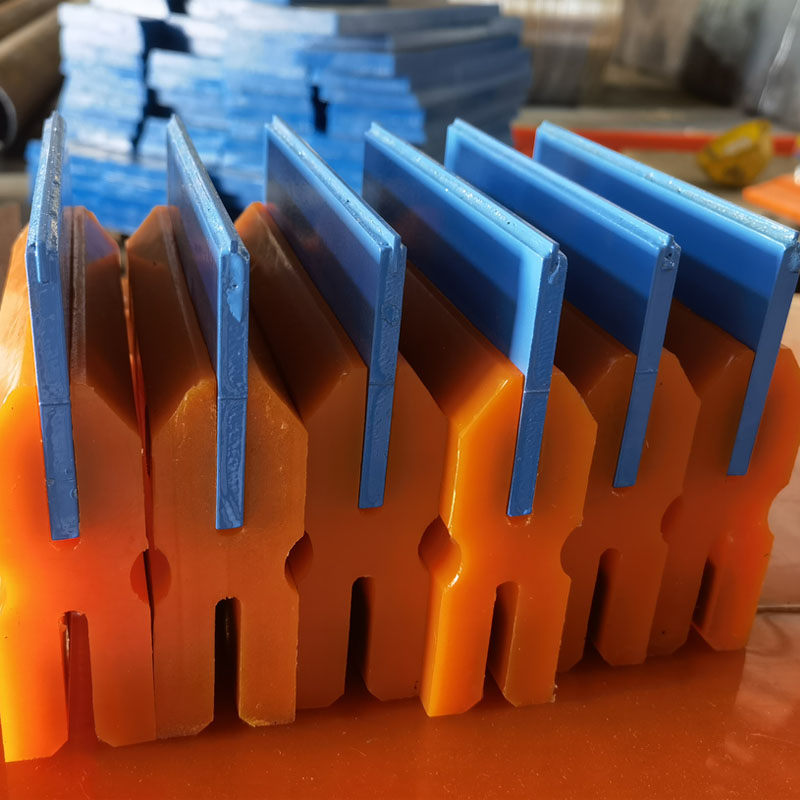

Y-shaped seal

-

The video of the conveyor tape

-

Sealing gasket

-

Type of fastening of the flange

-

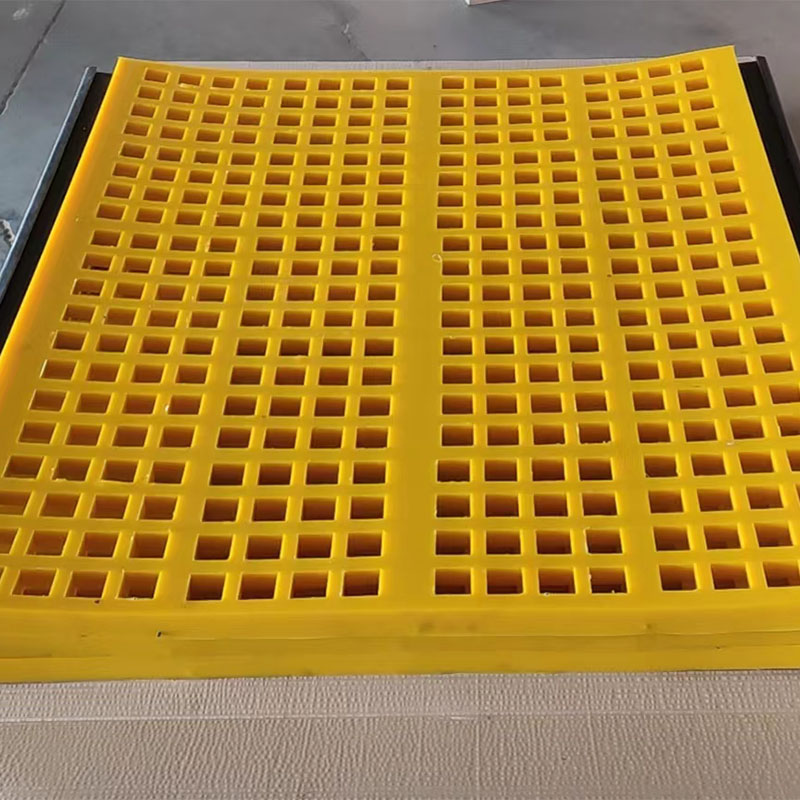

Sita mesh with tension

-

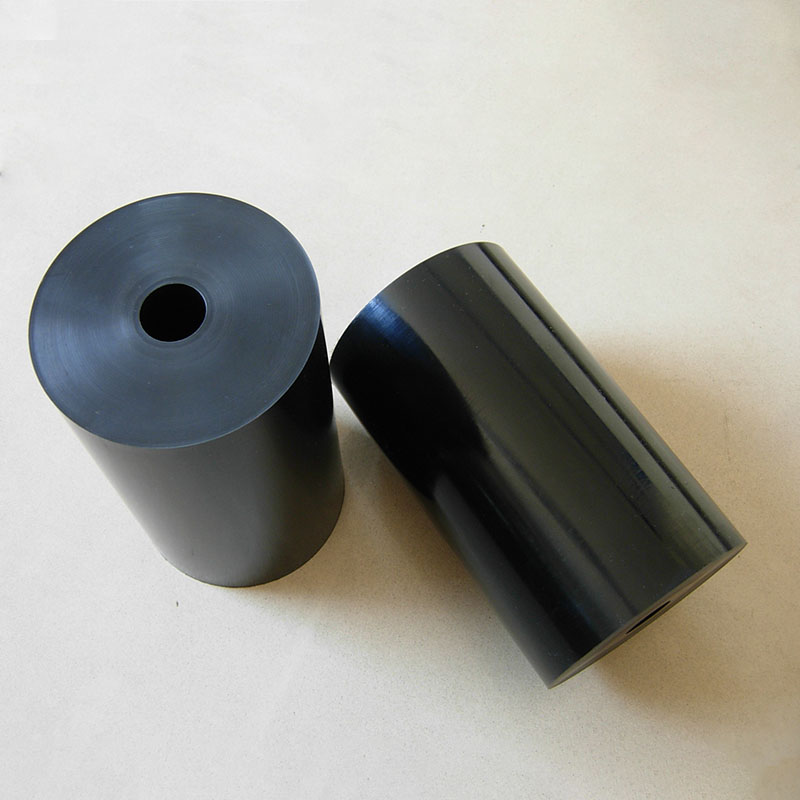

Polyurethane buffer

-

Drum screen

-

Polyurethane scraper

-

Sealing ring

-

The rod is wicker mesh

-

Polyurethane threaded videos

-

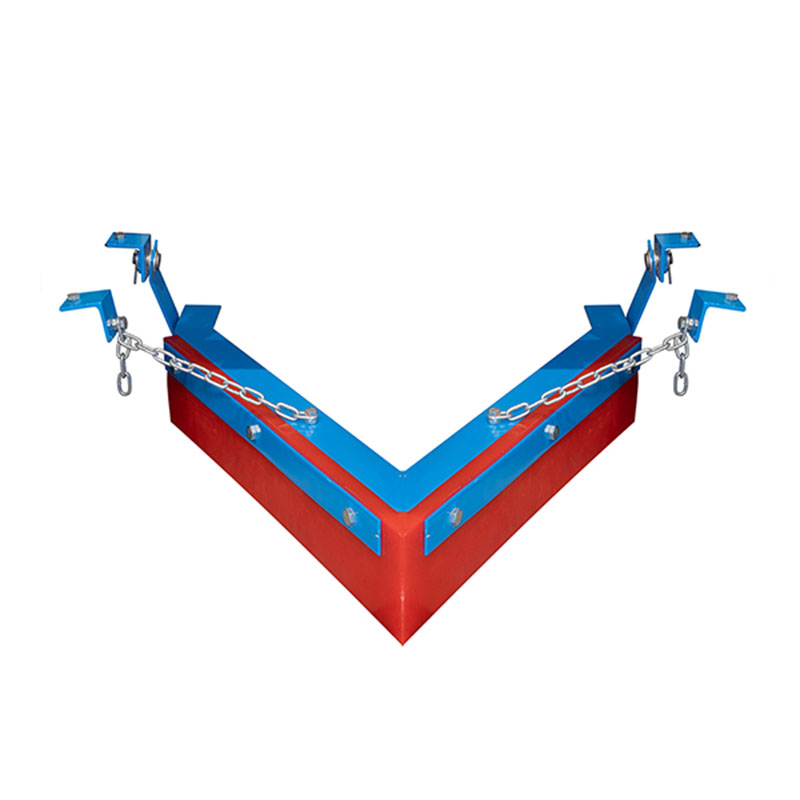

Polyurethane V-shaped video

-

Highlighting cover

-

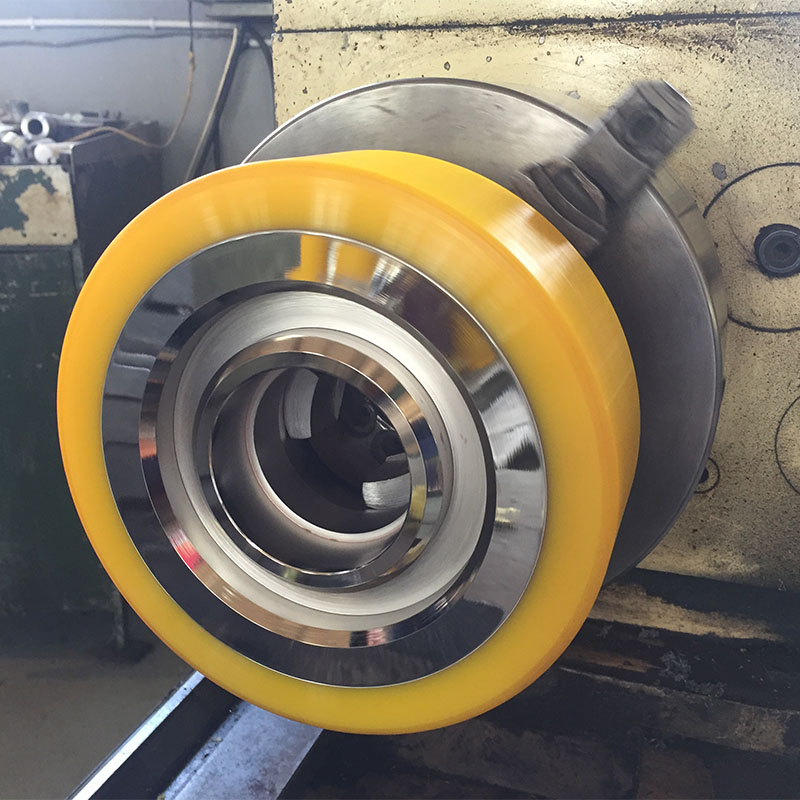

Heavy wheel

-

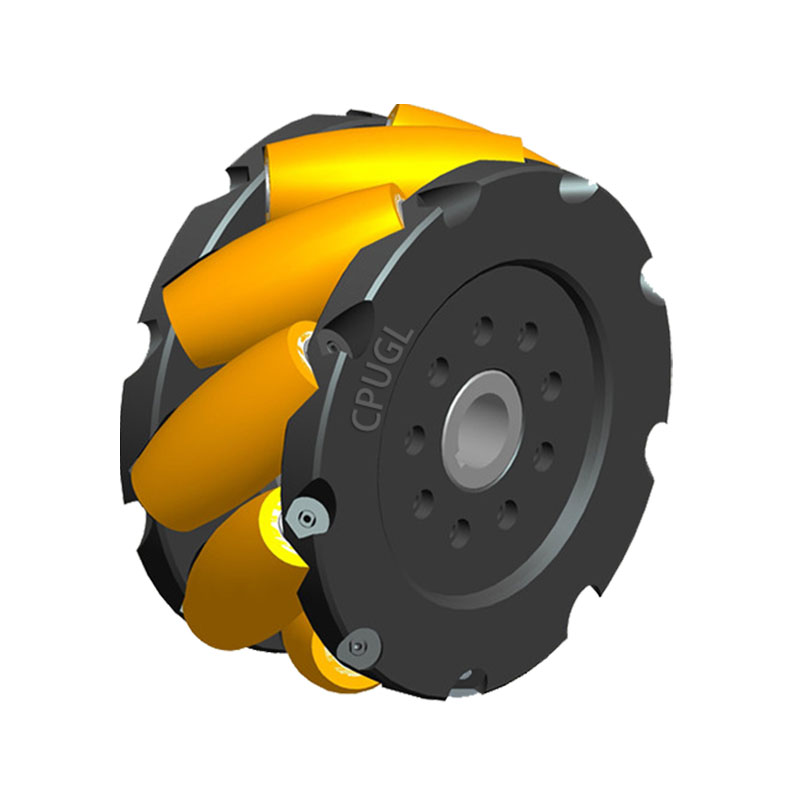

Mekanum Wheels

-

Polyurethane wear -resistant liner

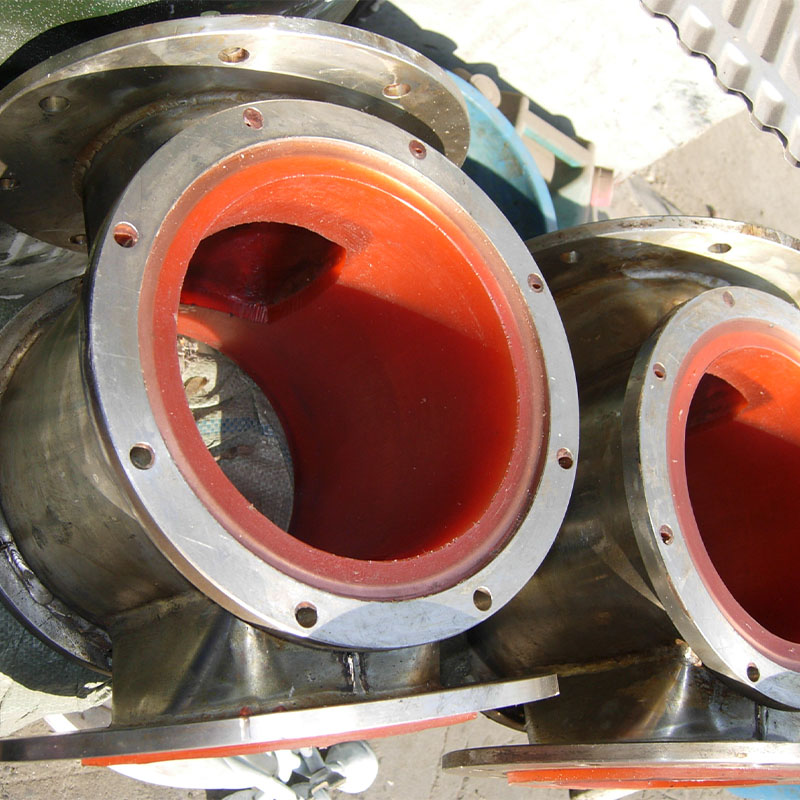

Polyurethane lining pipes

Operational characteristics 1. Coorful resistance to abrasion due to the fact that polyurethane lining has good elasticity, when exposed to the medium, polyurethane is forced to contract under the influence of external power, after the disappearance of external power, the polyurethane returns to the original state ...

Description

marker

Operational characteristics

1. Khurous resistance to abrasion

Due to the fact that the polyurethane lining has good elasticity, when exposed to the medium, polyurethane is forced to compress under the influence of external power, after the disappearance of external power, the polyurethane returns to the original state, this is “soft into hard”, significantly reducing the environment of the internal wall of the pipeline, directly caused by strong abrasion, and the wear resistance of a ten times exceeds the service life of the steel pipe.

2. Protection from scale.

The elastomer lined with polyurethane has a symmetrical molecular structure, external in the non-polar state, the formation of CA2+, CO32-, HCO3-, OH-ions in the adsorption suspension, and the shape of the scale layer. And the inner surface is smooth and elastic, which can prevent sticking the layer of scale, so it has the best characteristics to prevent and slow down the formation of scale.

3. Nice resistance

The surface of the lining is smooth and transparent, and the absolute roughness of the inner wall is 0.082, which allows reducing operational costs.

4. Khorous stability of water resistance and resistance to aging

This will not be like rubber products in the water will occur and will affect the use of performance.

5. A good combination

Polyurethane lining is closely combined with a steel pipe, using a unique process, cast polyurethane elastomer and a steel pipe reach a 100% combination, a unique overall sewing process, there will be no strait, dehollow and local phenomena of the gap.

6. lightweight, simple installation

Since a thin -walled pipe is used as a case, its weight is relatively small, and the connection method can be accepted during installation: flange connection, flexible pipe connection, welding connection.

The main application

Polyurethane composite steel pipe has excellent wear resistance, acid resistance, alkalinity, anti -nacquesiness, radiation resistance, resistance to hydrolysis aging, high elasticity, resistance to mechanical stress and other complex characteristics. It can be widely used in the electric power industry, coal, mining, the production of building materials, chemical industries and other industries for the transportation of coal dust, ash, mineral powder, aluminum fluid, suspension and other granular materials and aggressive media.

Energy industry: a pipe of ash, the gold pipeline, the recirculation pipeline of the gray water of the thermal power plant, for the fresh water of the power plant, the system of removing the ash of sea water and the transportation of acidic media using a polyurethane composite steel pipe can better reflect its superiority.

Coal industry: selection of heavy media on carbon installation and pipeline system for transporting coal over long distances. Pilling of deposits during coal mining.

Mining industry: iron ore slopes, mine concentrate, tail transportation system, a closed cycle of the shaft of the shaft of the mine, transporting water and sand during gold mining.

Building materials, chemical industry: transportation of coke particles at a metallurgical plant, transportation of dirt in the athumine factory basin, transportation of coal dust at a cement plant, transportation of aggressive acids, alkali, salts and corrosion hard and liquid substances, for example, transportation of pipelines in oil production, Dnieving work, the city water supply system, a pipe for transporting aluminum fluid, all this has an obvious effect.