Products

-

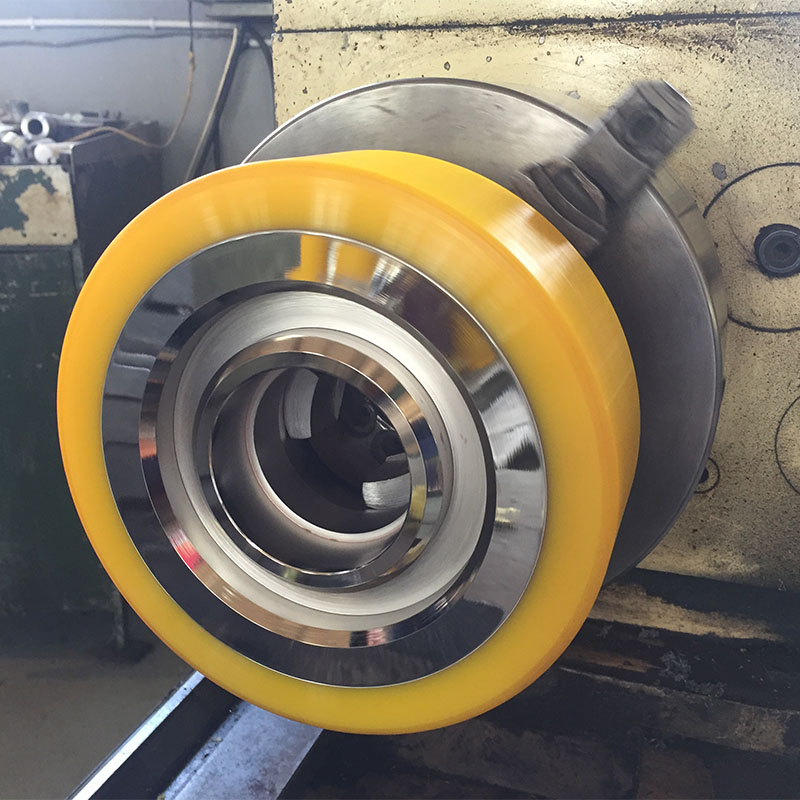

Wheels for robots

-

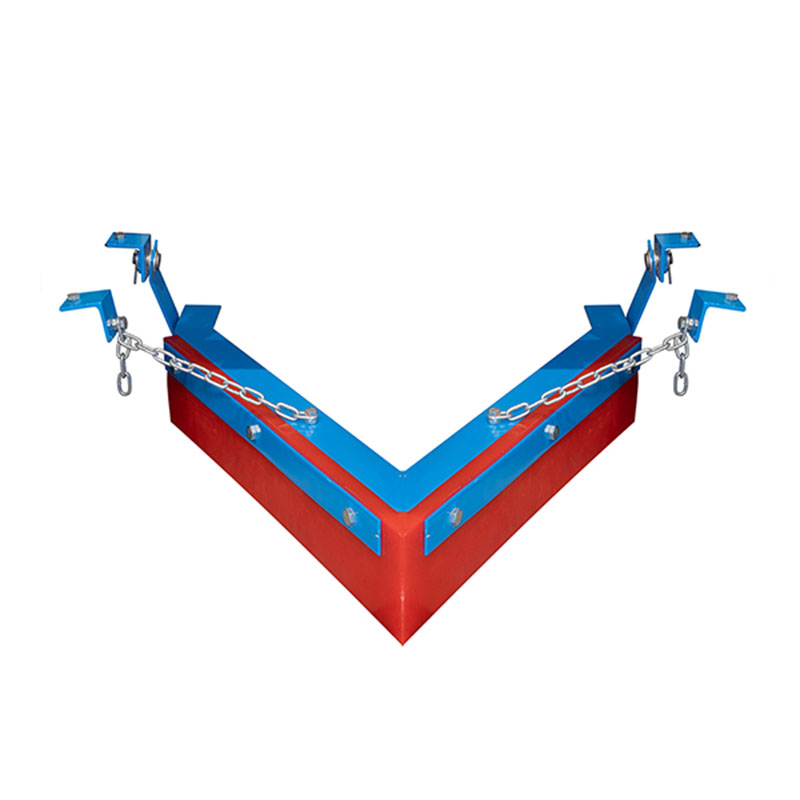

Polyurethane V-shaped video

-

Drum screen

-

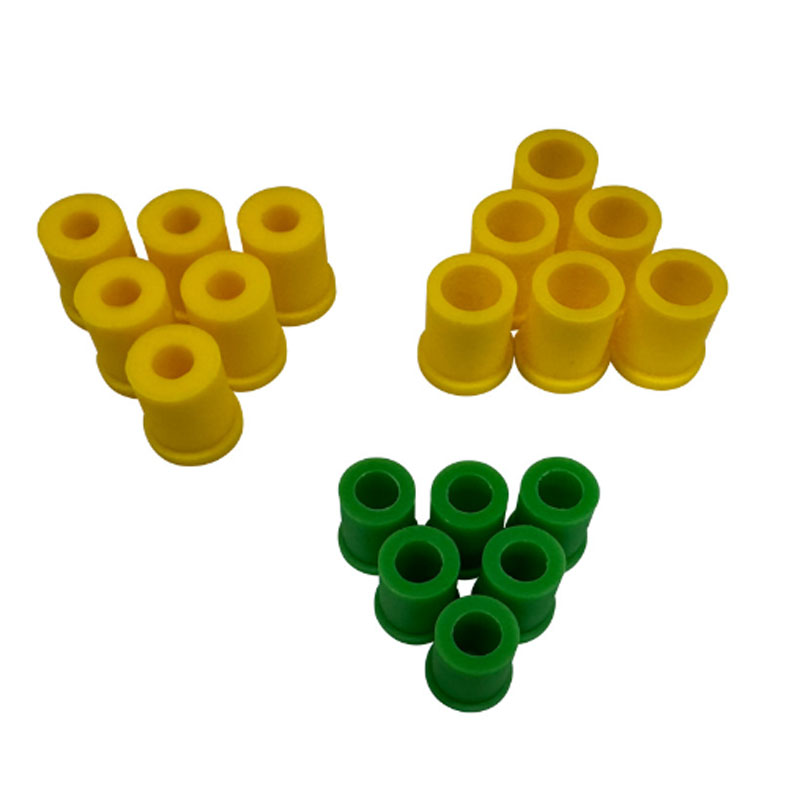

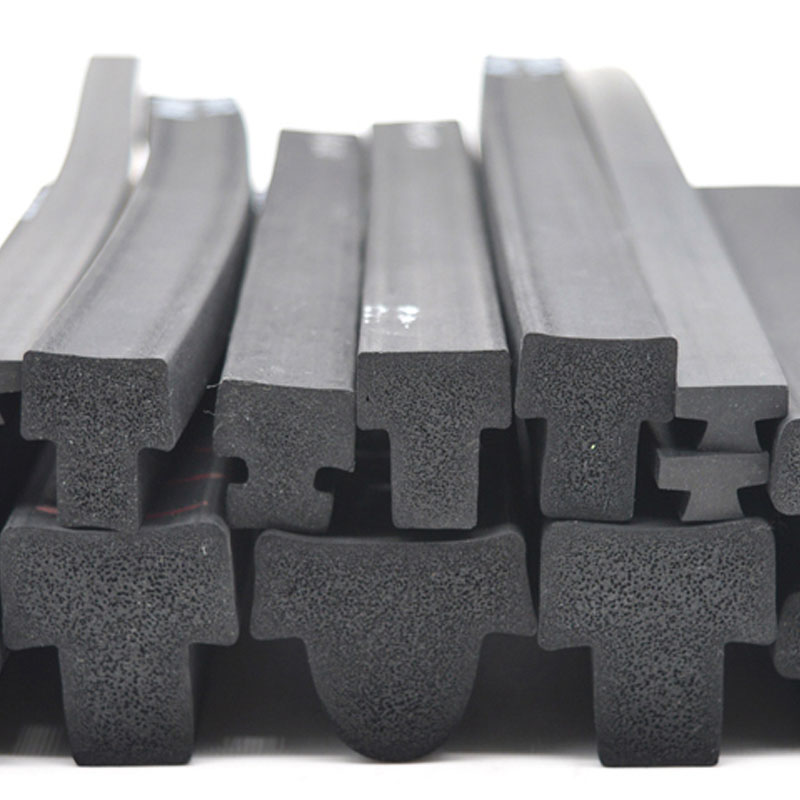

T-shaped seal

-

The video of the conveyor tape

-

Rounds for attractions and fitness equipment

-

Polyurethane buffer

-

Sealing tape

-

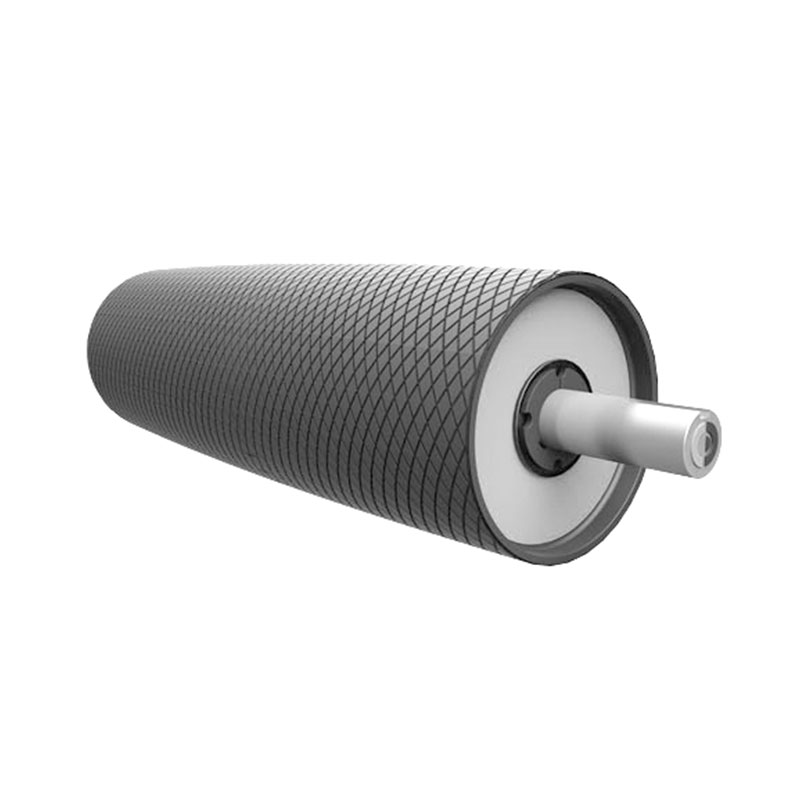

Polyurethane roller

-

Y-shaped seal

-

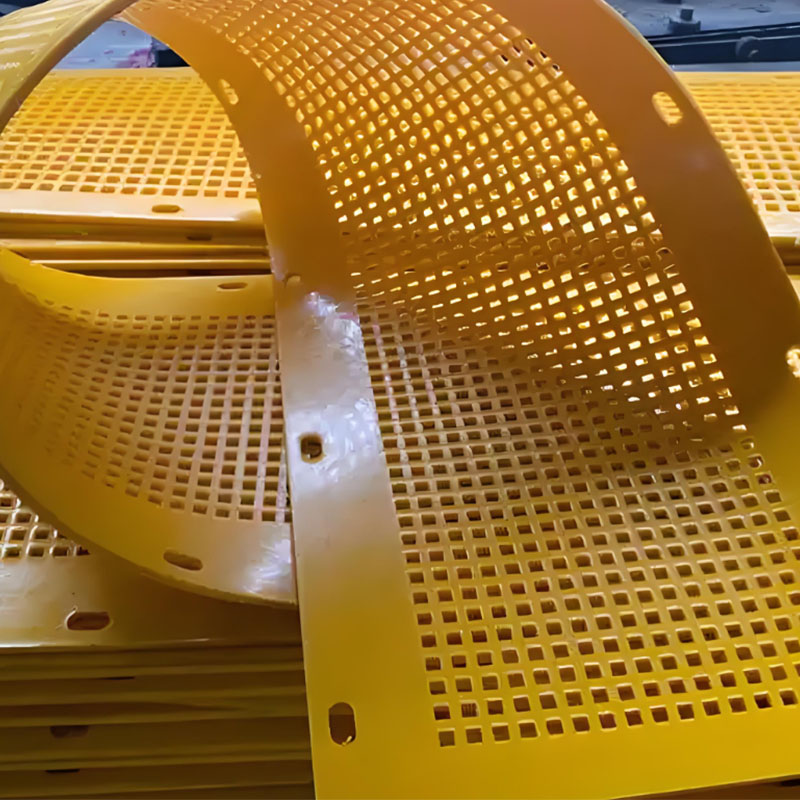

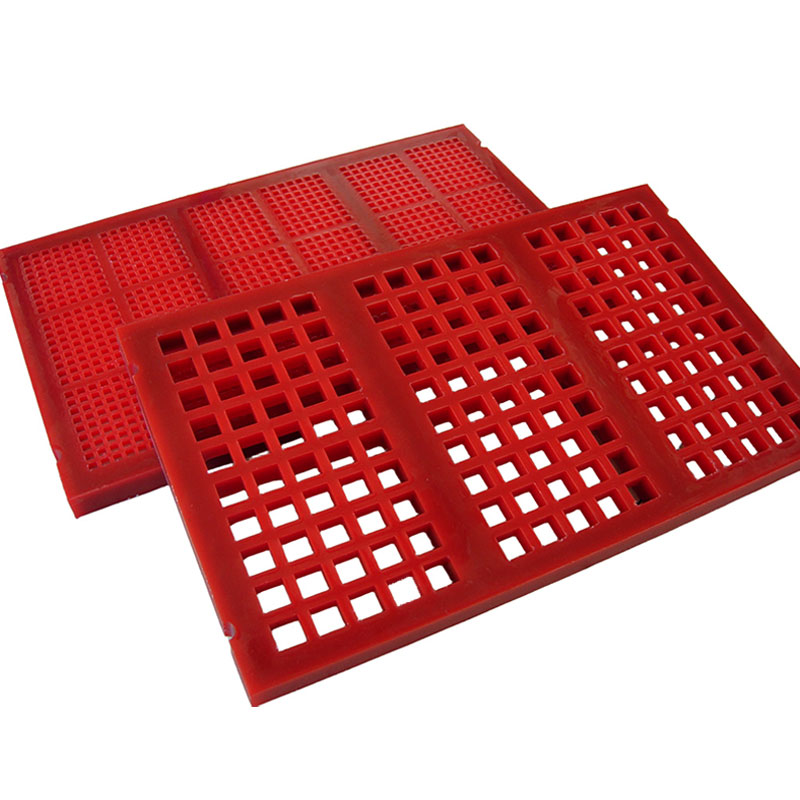

Polyurethane sieve for roar

-

Polyurethane print shafts

-

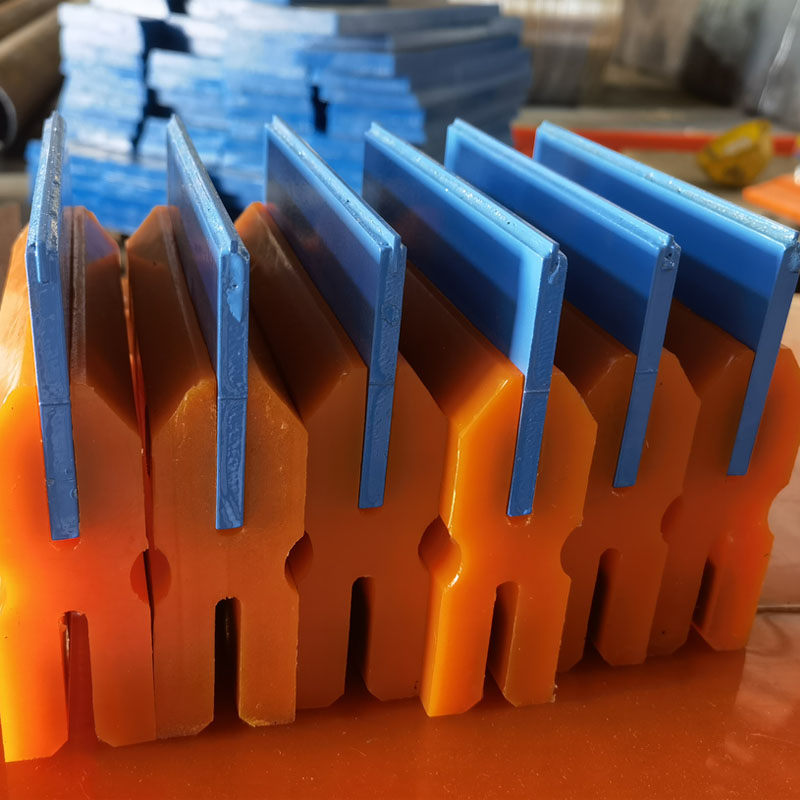

Polyurethane scraper

-

Polyurethane lining pipes

-

Highlighting cover

-

Polyurethane threaded videos

Assault seal

The principle of operation of the sealing sleeve is based on compression and elastic deformation. Placed in the gap between the components and applies pressure, it effectively stops the leakage of liquid or gas. Basic requirements for compaction: good tightness, safety and reliability, long -term Wed ...

Description

marker

The principle of operation of the sealing sleeve is based on compression and elastic deformation. Placed in the gap between the components and applies pressure, it effectively stops the leakage of liquid or gas.

The basic requirements for compaction: good tightness, safety and reliability, a long service life, while striving for a compact structure, simplicity of changes, ease of manufacture and maintenance, and low cost. Most of the seals are fast -digesting details, they should ensure interchangeability, standardization.

Usually used rubber sealing materials are mainly consisted of nitrile rubber, polyurethane rubber, fluerolastomer, silicone rubber, acrylate rubber, ethylene-protopylene rubber. Like more synthetic types of rubber, and their corresponding properties differ. For the right choice, you should rely on the characteristics of various types of rubber and the scope of application, taking into account the conditions of operation of the seals.