Rollers for conveyor tape

Rollers for conveyor tape: types, application and choice

Rollers for conveyor tape are perhaps the most inconspicuous, but very important element of the entire conveyor system. They perform an indispensable function, providing smooth and reliable movement of goods. Imagine a long ribbon, which without rollers will simply fall under the weight of the cargo, or get stuck, which will lead to a slowdown in the whole process. That is why the choice of correct videos is critical for the effectiveness and durability of the conveyor.

Types of rollers for conveyor tape

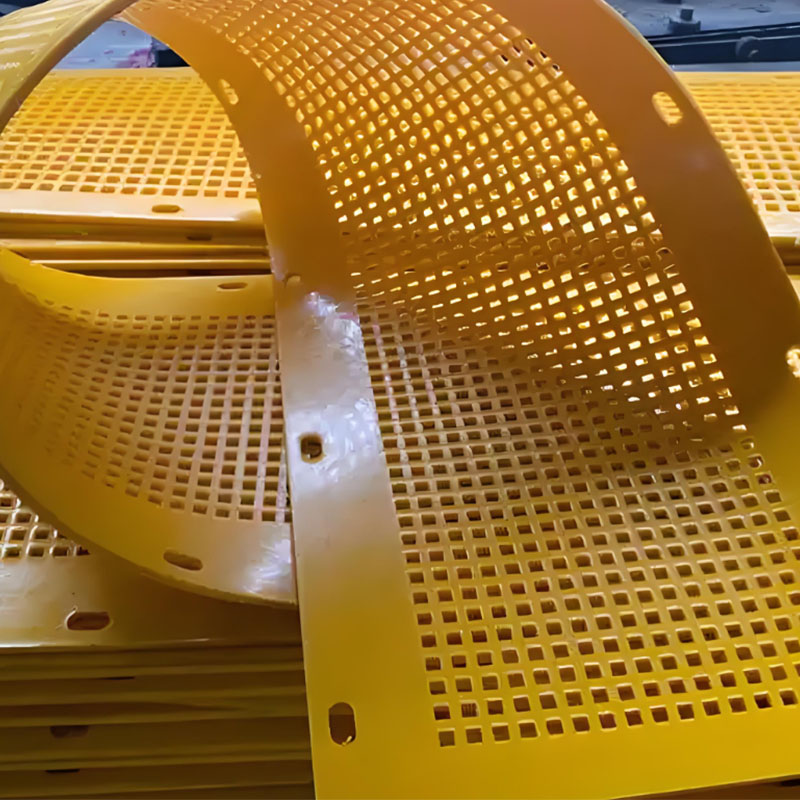

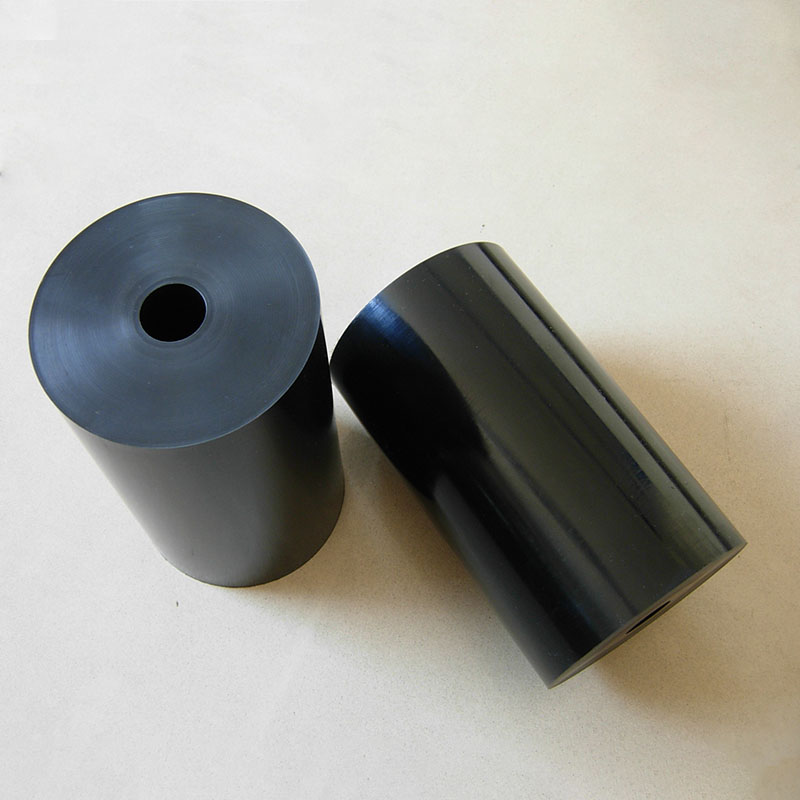

There are many types of videos, each of which is designed for specific tasks. Some are ideal for light cargo and low load, others for heavy industrial conditions. For example, videos with a metal case and hard bearings will cope perfectly with the transportation of bulk materials. For food or medicines, it is better to choose stainless steel clips to ensure maximum hygiene. There are also videos with various coatings that protect the tape from wear, and rollers with a variable height to adapt to various loads. The choice depends on the features of the cargo, the angle of inclination of the conveyor, and the total volume of work.

Application of rollers in various industries

Rollers for conveyor tape are widely used in various industries. From the food industry to the production of metal rolling, from logistics centers to warehouses of building materials - wherever it is necessary to transport goods, conveyors with correctly selected rollers are irreplaceable. For example, in the food industry it is important that the rollers are made of food steel, ensuring the safety of products. In the workshops for the production of metal rolling, where the load can be very heavy, videos with increased carrying capacity are used. The selection of rollers is not just a matter of savings, it is the key to the smooth operation of the entire production.

How to choose the right videos?

When choosing videos, several factors must be taken into account. The carrying capacity is important - the rollers should withstand the weight of the transported goods. The material from which the rollers are made should comply with the requirements of a particular application (hygienicity, resistance to corrosion, resistance to abrasion). Their strength and durability are also important to minimize the cost of maintenance. It is necessary to carefully study the technical characteristics of each type of rollers in order to ensure the optimal choice. Pay attention to the recommendations of the manufacturer of the conveyor tape to avoid damage and problems.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Prices for round rubber seals in China

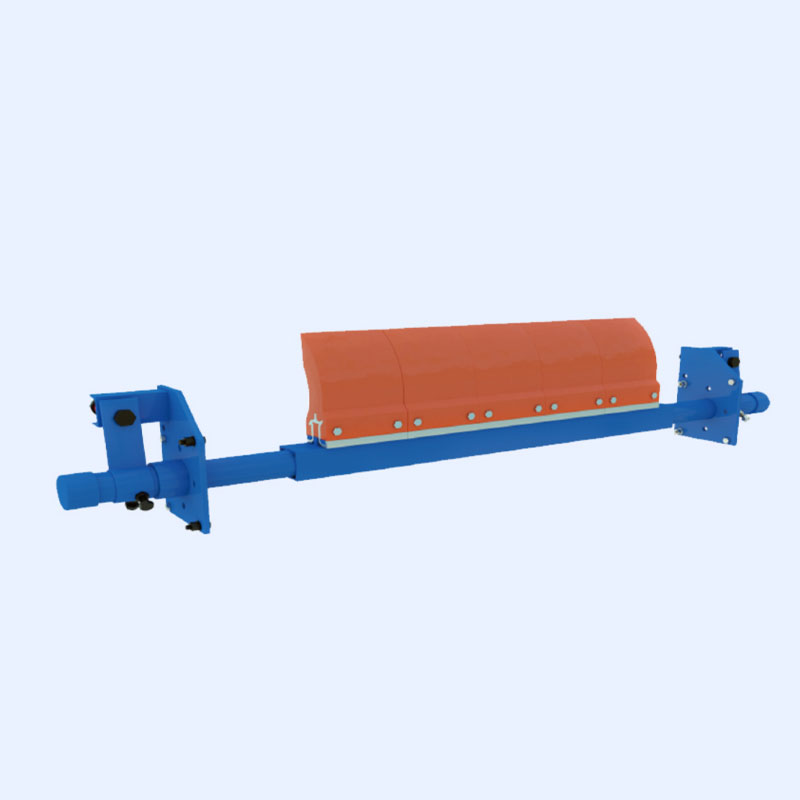

- Cleaner of the ribbon conveyor of the return, empty section of the V-shaped supplier

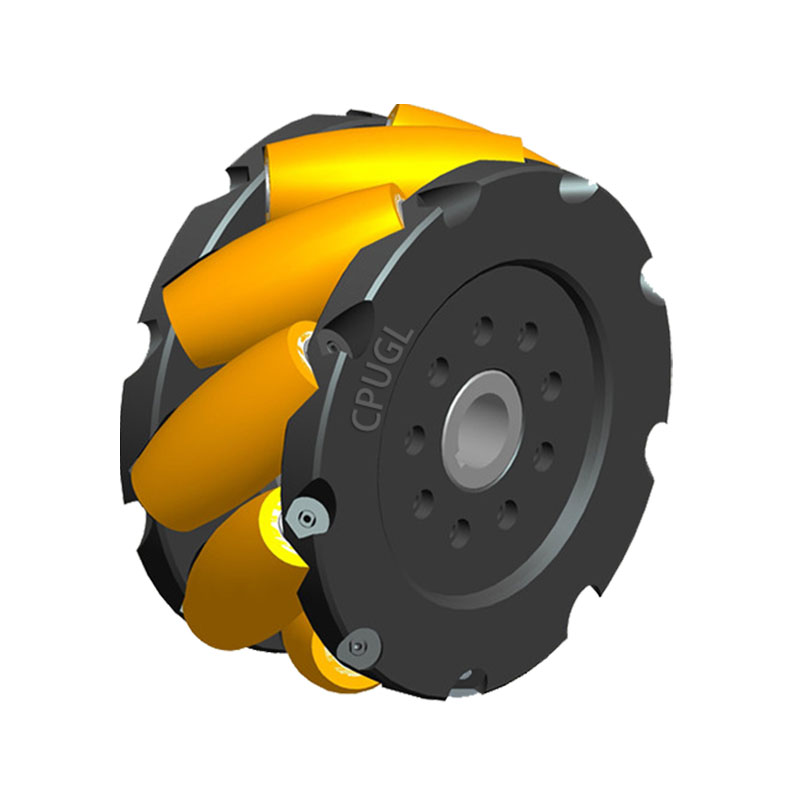

- Certy wheel

- Polyurethane wheel buyers with a bearing in China

- Rubber Rings Round Round

- Prices for the lower spring spacers in China

- A whole -lit wheel of polyurethane

- Polyuretan Prutok wholesale

- Chinese suppliers Utthane wheels of bison

- Chinese manufacturers spring profiles VAZ 2107