Rubbed shafts

Rubberized shafts: a reliable solution for various tasks

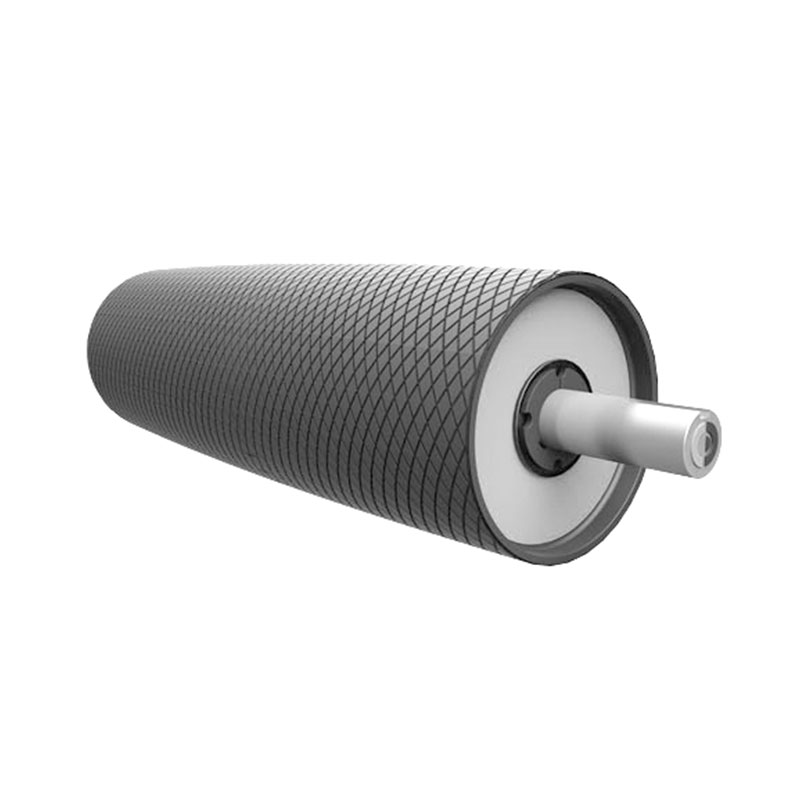

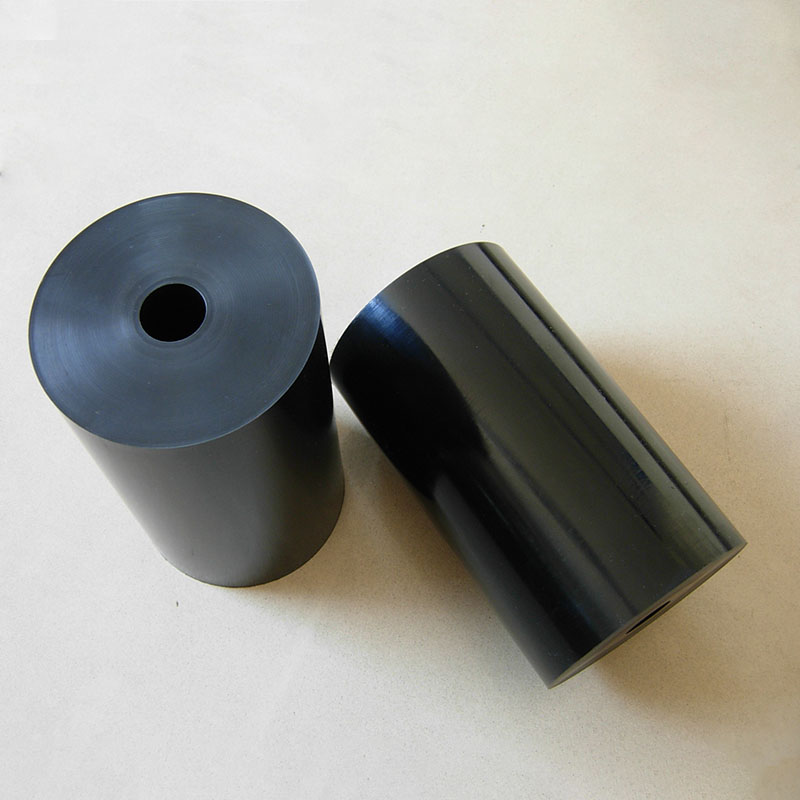

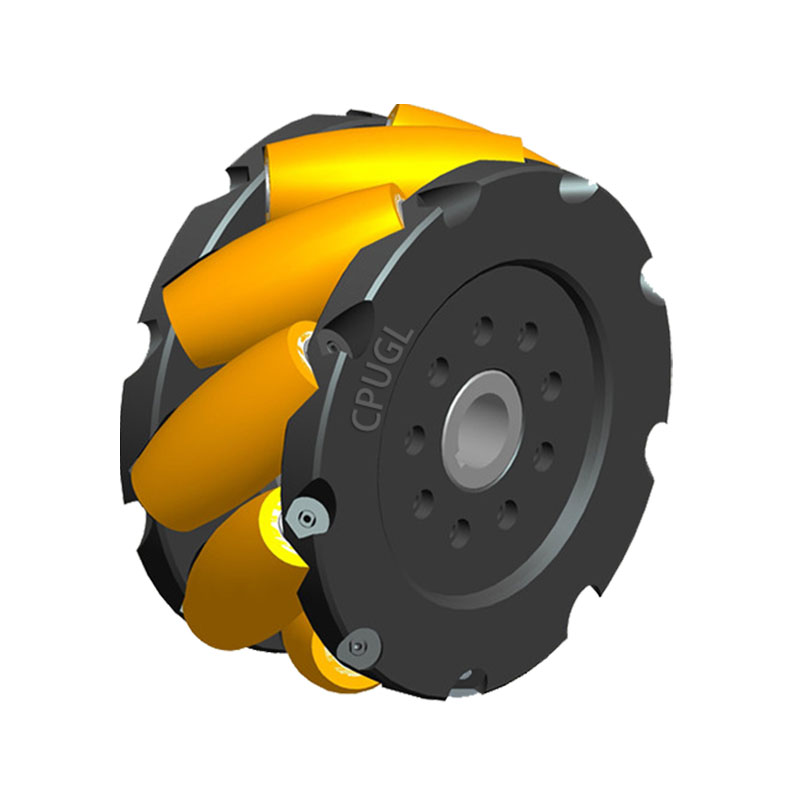

Rubbed shafts are shafts covered with a layer of rubber. At first glance, it may seem that this is just a layering, but in fact it has a significant impact on the work of mechanisms. Rubber, thanks to its properties, prevents the wear of parts, reduces vibration and noise, and, importantly, ensures uninterrupted operation. Imagine: instead of the metal parts of the rubbing against each other, we get smooth and elastic interaction, as if two surfaces gently hug each other.

Advantages of rubberized shafts

The main advantage is a decrease in friction. Due to the elasticity of rubber, the shaft becomes softer, which significantly reduces the wear of both the shaft and other details with which it interacts. This, in turn, leads to lower costs for repair and replacement. In addition, the rubberized shafts perfectly extinguish vibration and noise, which makes the operation of the mechanism more comfortable and quiet. Imagine how pleasant it is to work with a tool that does not vibrate and does not make noise! This is important, especially in the conditions of production. Finally, rubber often has excellent resistance to various aggressive environments, protecting the corrosion shaft and prolonging its service life.

Area of application of rubberized shafts

Rubbed shafts are used in a very wide range of areas. From the food industry and pharmaceuticals to machine tools and engineering. For example, they can be used in conveyor ribbons, printing mechanisms, food rollers. Due to its flexibility and resistance to various conditions, the rubberized shafts become an indispensable component in many machines and mechanisms, where reliability and durability are needed. In the food industry, for example, rubberized shafts guarantee the safety of the product, preventing metal particles.

The choice of rubberized shafts

When choosing a rubberized shaft, it is important to consider several factors. It is necessary to choose the right type of rubber, given the specifics of the future load and the effects of the medium. The thickness of the rubber layer is also important. A variety of types of rubber and parameters allows you to select the best option for a specific task. Pay attention to the manufacturer and quality certificates - this is a guarantee of the reliability and durability of the product. Use the recommendations of specialists if you have doubts.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

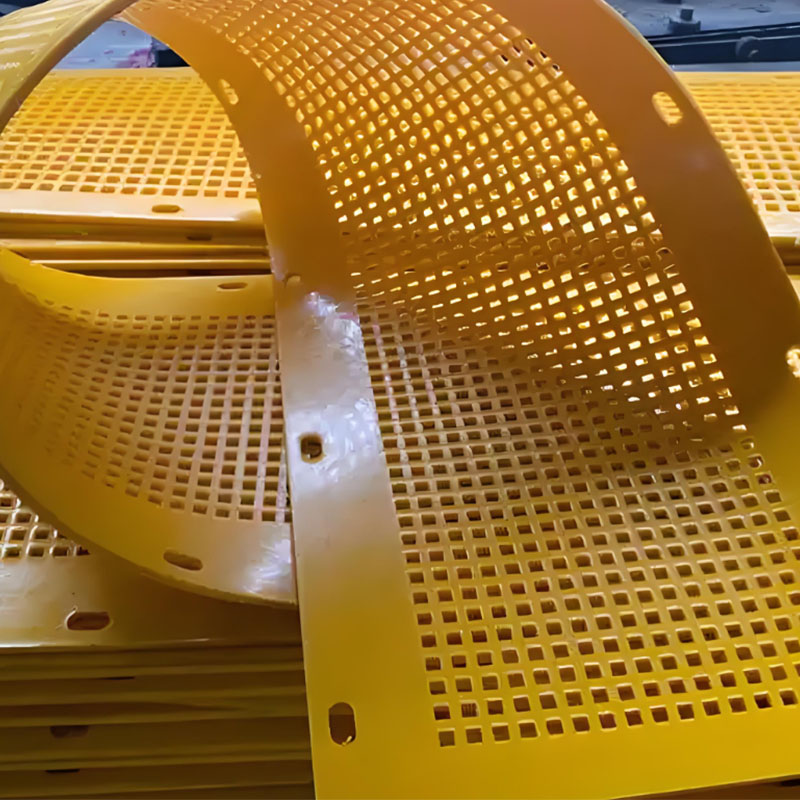

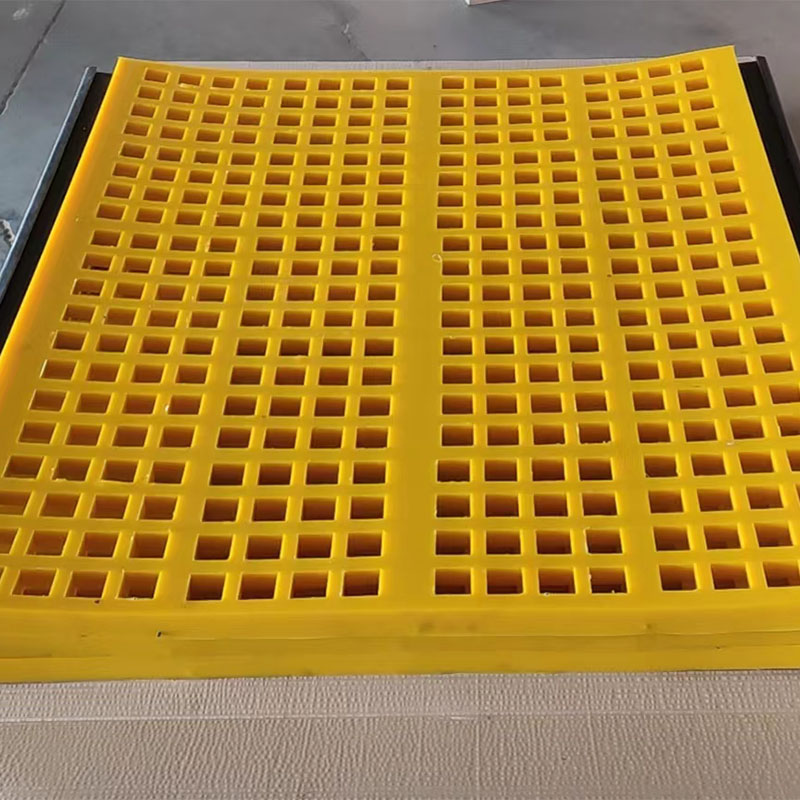

Related search- Polyurethane inserts

- Sita for the roar of polyurethane in China

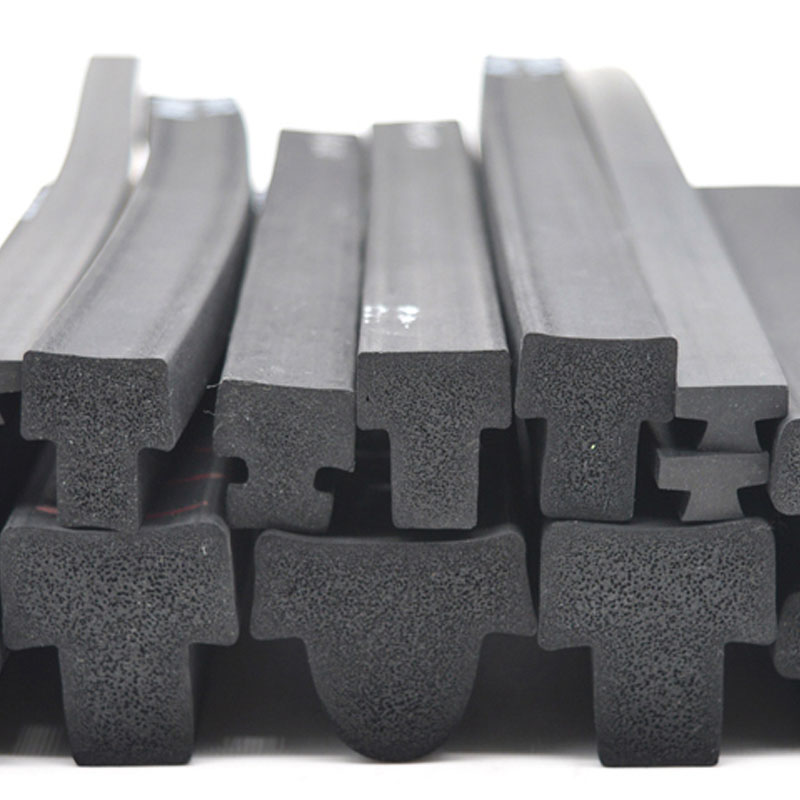

- Claiming

- Polyurethane scraper buyers for conveyor ribbons in China

- The best countries-buyers of seals for mixers in China

- Chinese suppliers of filter gaskets

- Buy thermocles of the rod

- Lining sear filter manufacturer

- conveyor bearing rollers in China

- Wheel for a car polyurethane all -liter buy