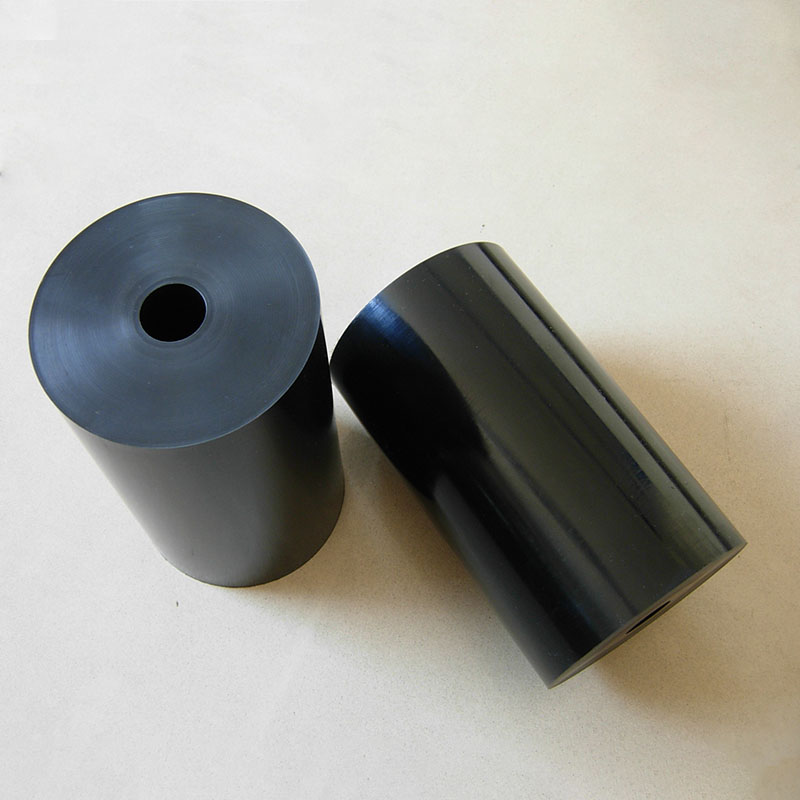

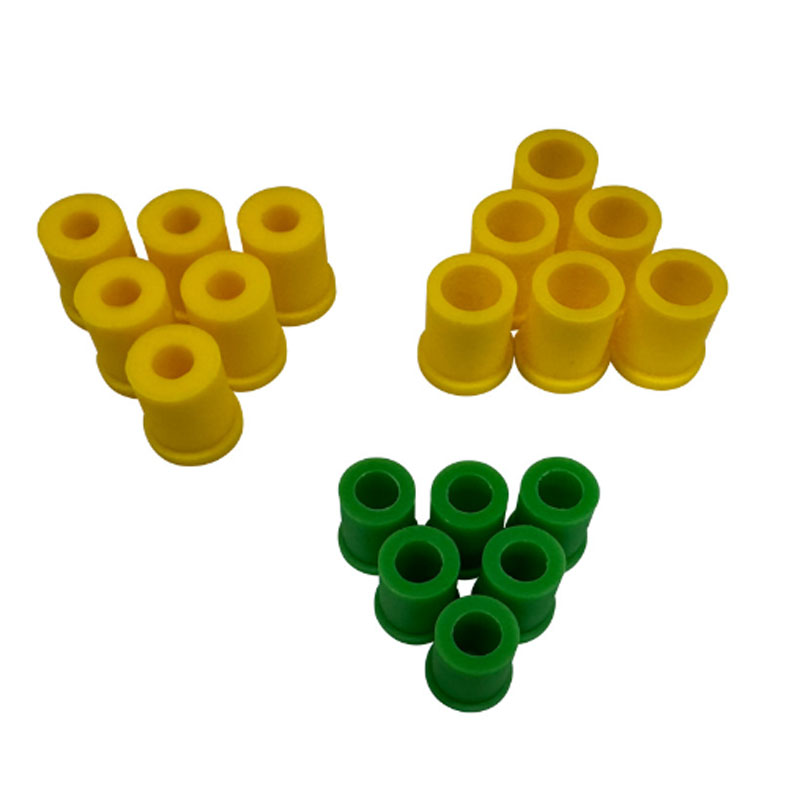

manufacturer of polyurethane buffer for cranes

Manufacturer of polyurethane buffers for cranes

Polyurethane buffers for cranes are indispensable assistants in ensuring smooth and safe work. Imagine a mechanism that will avoid shocks, creaks and breakdowns that occur in contact of various parts of the equipment. It is for this that these buffers are created.

How do polyurethane buffers work?

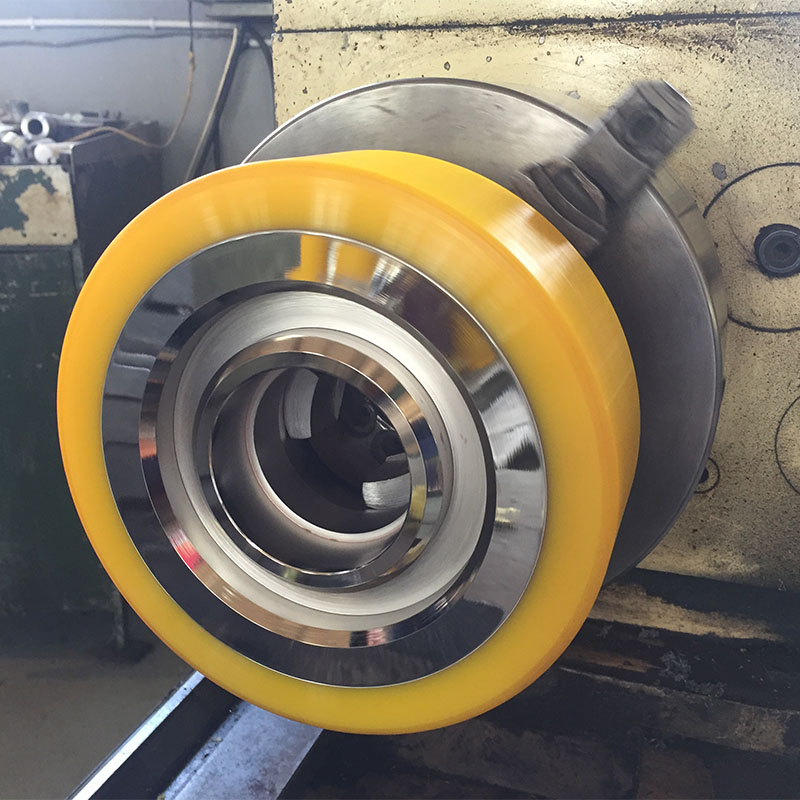

Boofers made of polyurethane have unique properties. They are able to absorb shock loads that occur during movement and reduce vibrations. Polyurethane is a rather strong and elastic material that provides reliable protection against damage, preventing collision and wear of the crane parts. It is like a soft shock absorber that carefully carries out the mechanism through all the stages of work. Thanks to this absorption, the buffers extend the service life of the crane and reduce the risk of damage. Their work is based on the ability of the material to deform under the influence of the load and return to the initial state, without losing its properties.

Advantages of using polyurethane buffers

The advantages of using polyurethane buffers are obvious. Firstly, this is safety. They exclude sharp blows and potential injuries associated with the operation of mechanisms. Secondly, this is an increase in efficiency. The smooth movement of the mechanism, without unnecessary noise and vibrations, contributes to better and productive work. Thirdly, this is durability. Polyurethane is a durable material that is able to withstand significant loads and long -term work cycles, minimizing the need for frequent replacement. And finally, polyurethane buffers are savings. A decrease in the frequency of breakdowns and the need to carry out repairs lead to significant savings of resources spent on maintenance and repair of equipment.

Choosing a buffer manufacturer is an important stage

When choosing a manufacturer of polyurethane buffers for cranes, it is important to pay attention to the quality of the material used, the accuracy of manufacture and warranty. A reliable manufacturer will make sure that the buffers correspond to the specifics of your equipment, ensuring its safe and uninterrupted operation. Pay attention to the reputation of the manufacturer and reviews of other customers - this will help make the right choice and get a quality product. It is important that the buffer element is not only strong, but also corresponded to your specific needs, and is produced in compliance with all safety standards.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Shock -absorbing bolts in China

- The main countries of the sealing rings for draining from China

- Pucks of the pucks of the rear springs of the VAZ in China

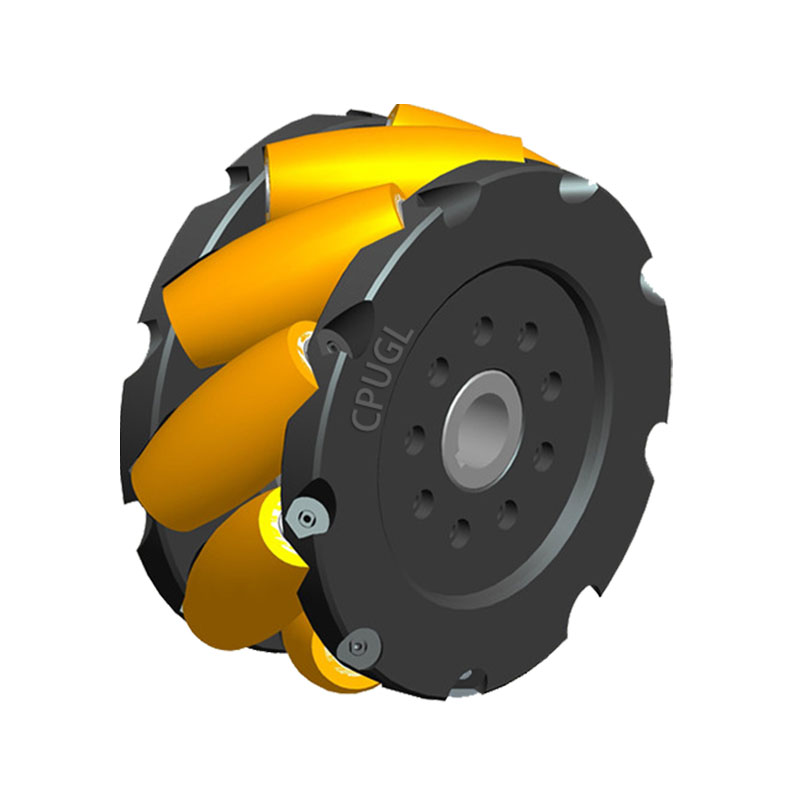

- Gumming of the wheels

- Prices for spring washers Kia in China

- Suppliers of seals in China

- Wheel for a car Polyurethane all -liter buy a manufacturer

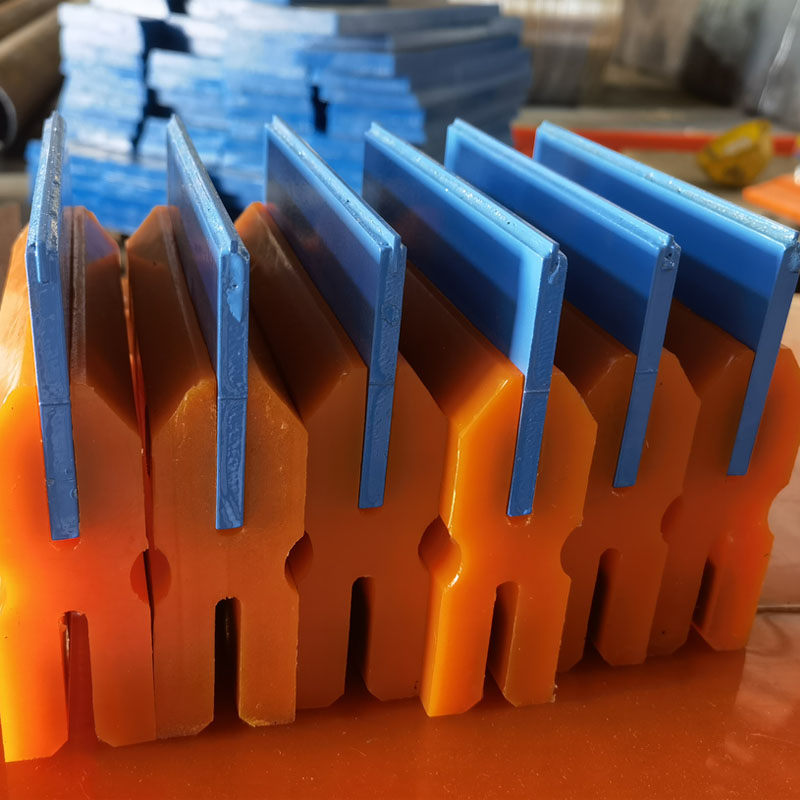

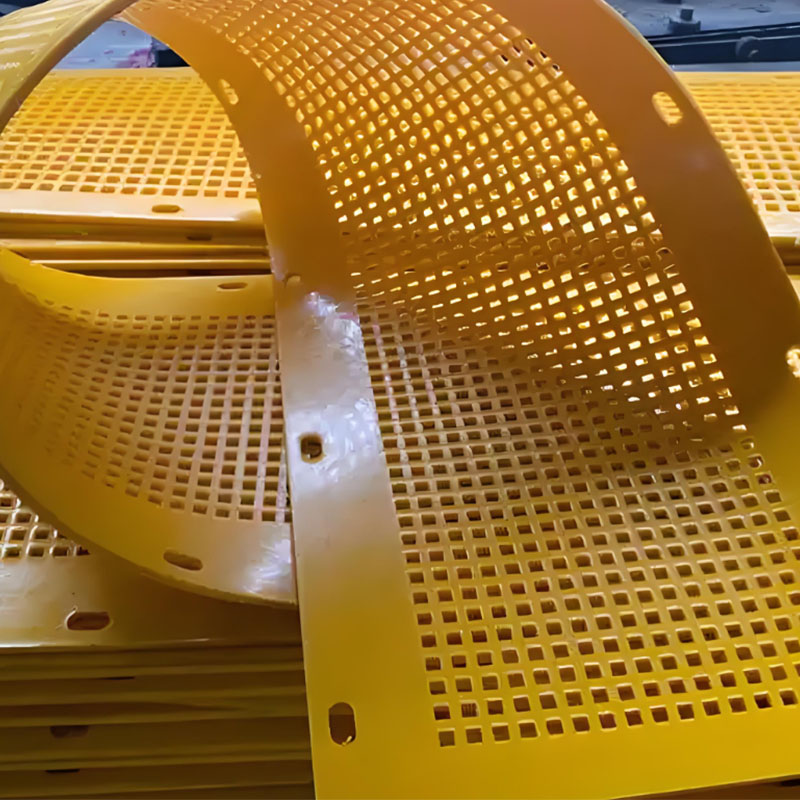

- Suppliers of Polyurethane Sit Panels from China

- Polyurethane wheel 3.00 8

- Y-shaped seal in bulk