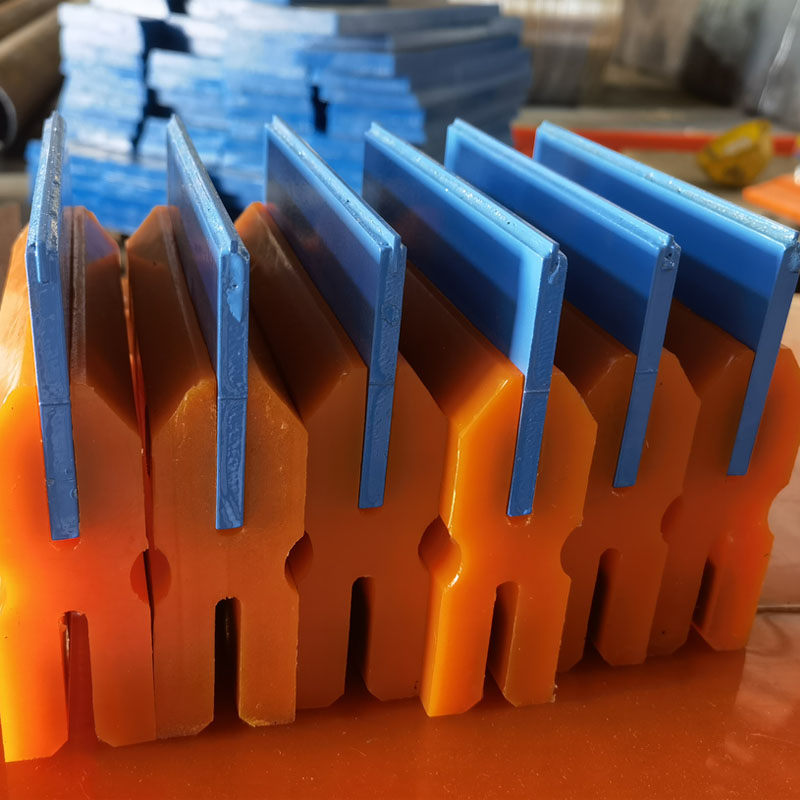

Polyurethane scraps for conveyor tapes

Polyurethane scraps for conveyor tapes

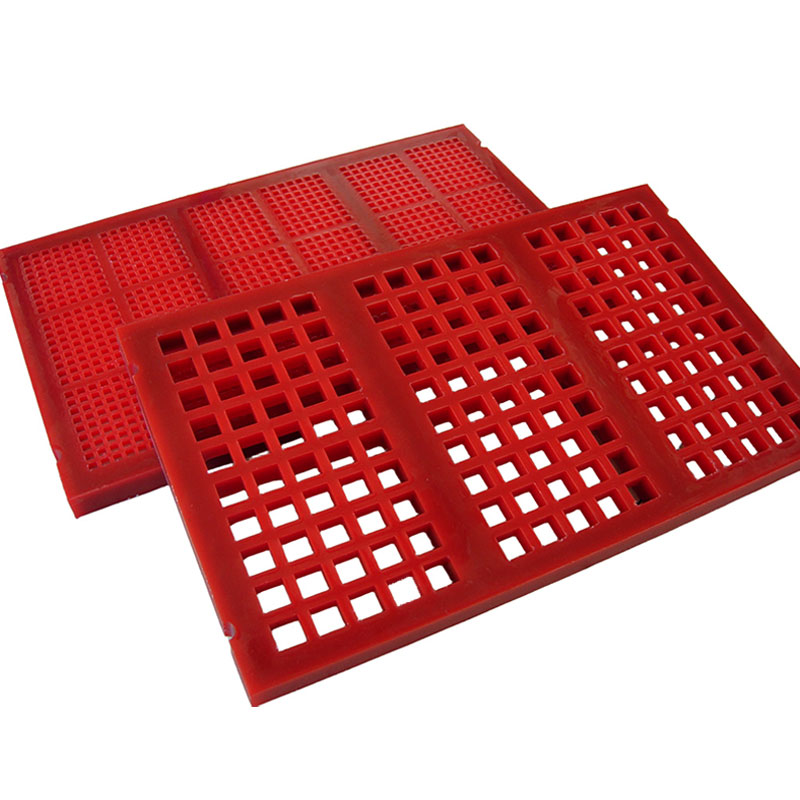

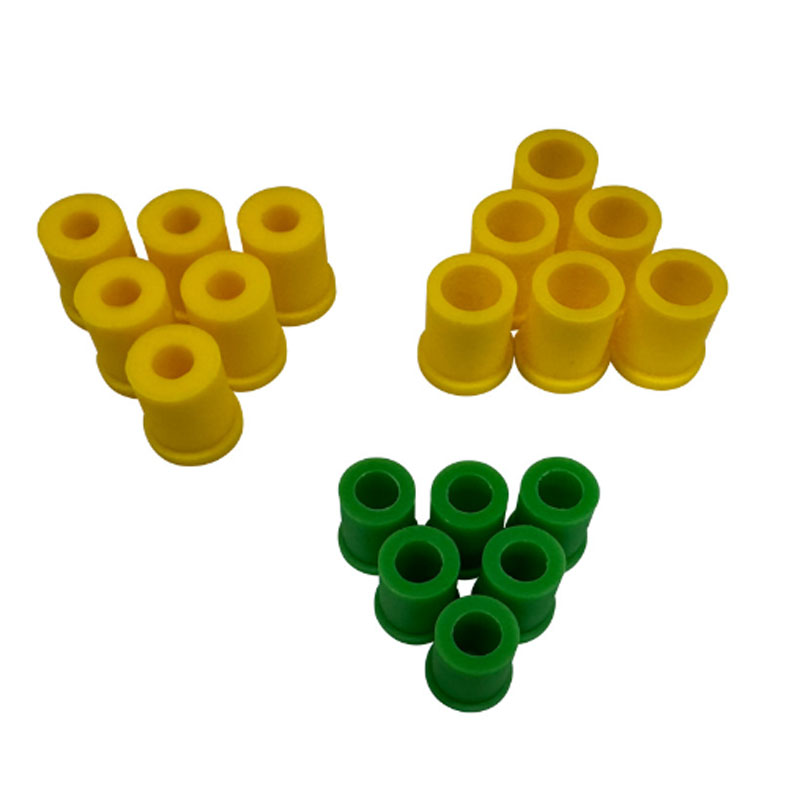

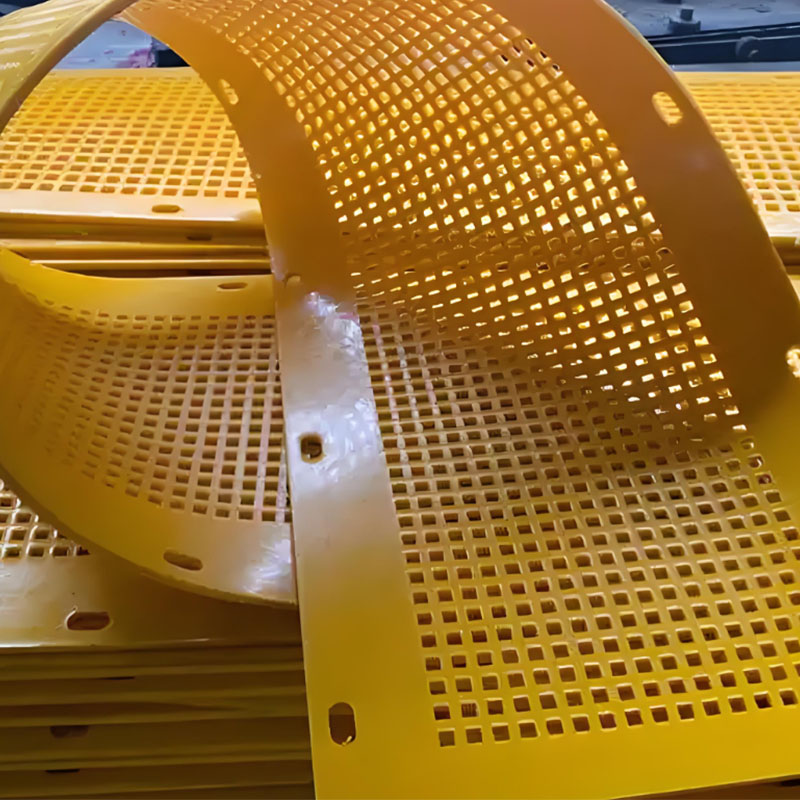

Polyurethane scrapers are indispensable assistants in the work of conveyor systems. They ensure the effective removal of the remnants of materials, preventing their accumulation and pollution of the conveyor. Imagine a long tape on which the products are constantly moving. In order for this tape to work uninterruptedly and efficiently, you need to remove all the excess. It is for this purpose that polyurethane scrapers are used.

Advantages of polyurethane scrapers

Polyurethane is an amazing material with high wear resistance, elasticity and chemical resistance. This means that scrapers from it can withstand significant loads without deforming and not destroying when contacting a variety of materials. They also gently but effectively clean the conveyor tape, preventing premature equipment wear. In addition, polyurethane has excellent resistance to various aggressive environments, which makes it an ideal choice for working with chemically active substances.

A variety of application

Polyurethane scrapers are used in a wide range of industries, where conveyor equipment is used. This can be the production of food products where hygiene is important, or metals processing, where scrapers should withstand high temperatures and loads. When choosing a scraper, it is important to take into account the type of product that moves along the tape, and the specifics of production. For some types of cargo, for example, grain, a more aggressive scraper may be needed, and for thin products, for example, powders, a scraper with a softer coating.

Choosing a scraper: Buyer tips

Before buying a polyurethane scrap, pay attention to several important parameters. First, decide on the type of conveyor and the features of the work. The next step will be the determination of the characteristics of the product that will be transported by the conveyor. Then it is necessary to evaluate the intensity of work and operating conditions. Pay attention to the thickness and composition of polyurethane, as well as the features of fastening the scraper to the conveyor. Professional consultations of the supplier will help in choosing the most suitable scraper for specific tasks. It is important to remember that the correct selection of a scrap is a contribution to the long -term and uninterrupted operation of your conveyor.

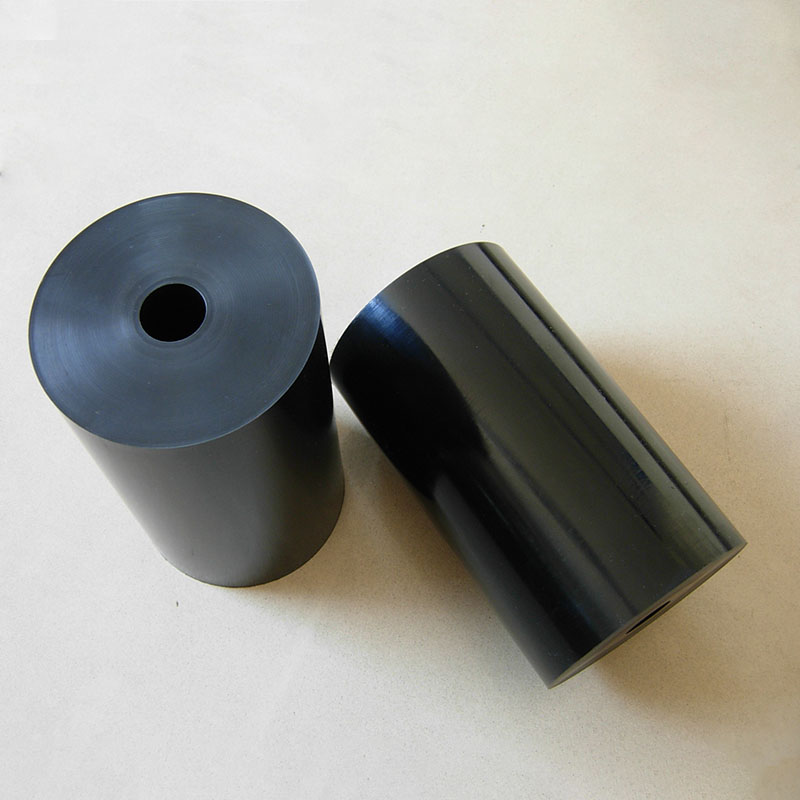

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

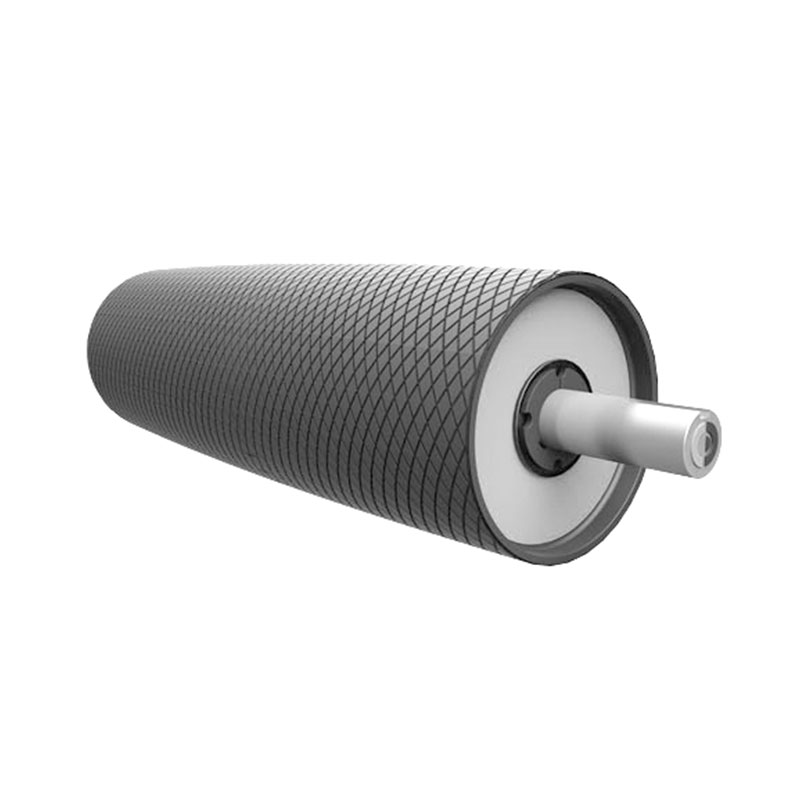

Related search- The rollers are conveyor smooth

- Laying chipped filter

- Sealing plants in China

- Grocery laying 3 4 in China

- Front springs of the Niva

- Polyurethane wheels rubber supplier

- polyurethane wheel with a bearing in China

- Manufacturers of spring clamping planks for Niva in China

- The main countries of searching for brake polyurethane universal wheels from China

- Suppliers Seal gasket PRP diameter 30 mm from China