Products

-

Cleaner of the reverse air section

-

O-shaped seal

-

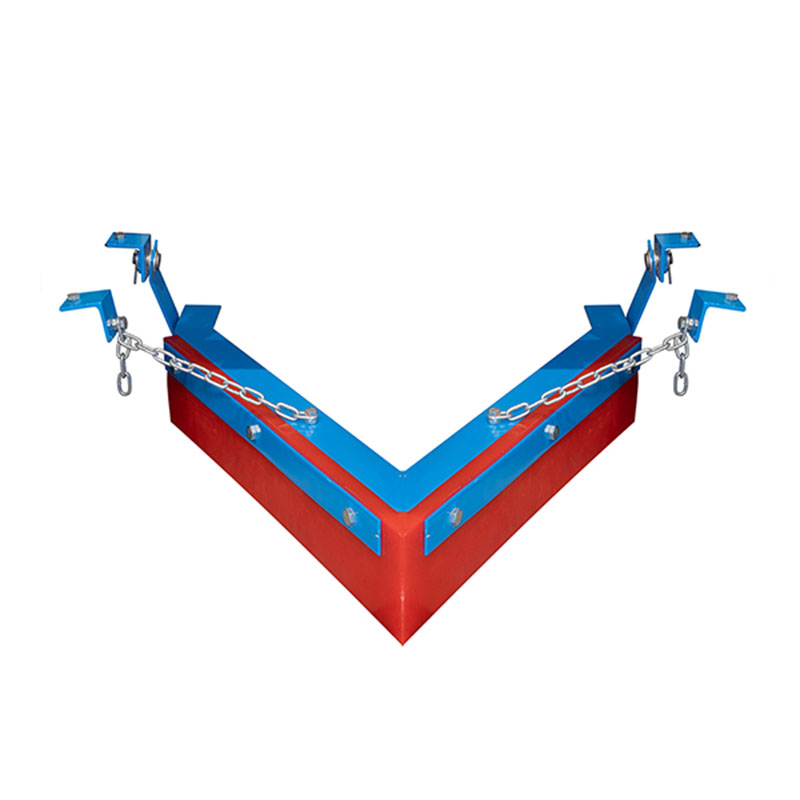

Polyurethane V-shaped video

-

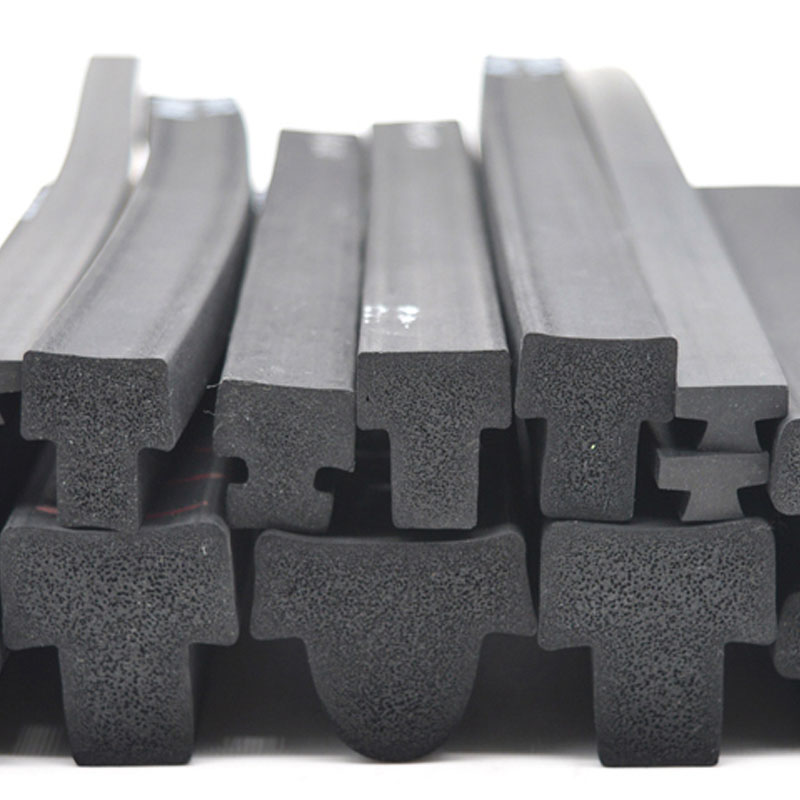

Sealing gasket

-

Bolt type of fastening

-

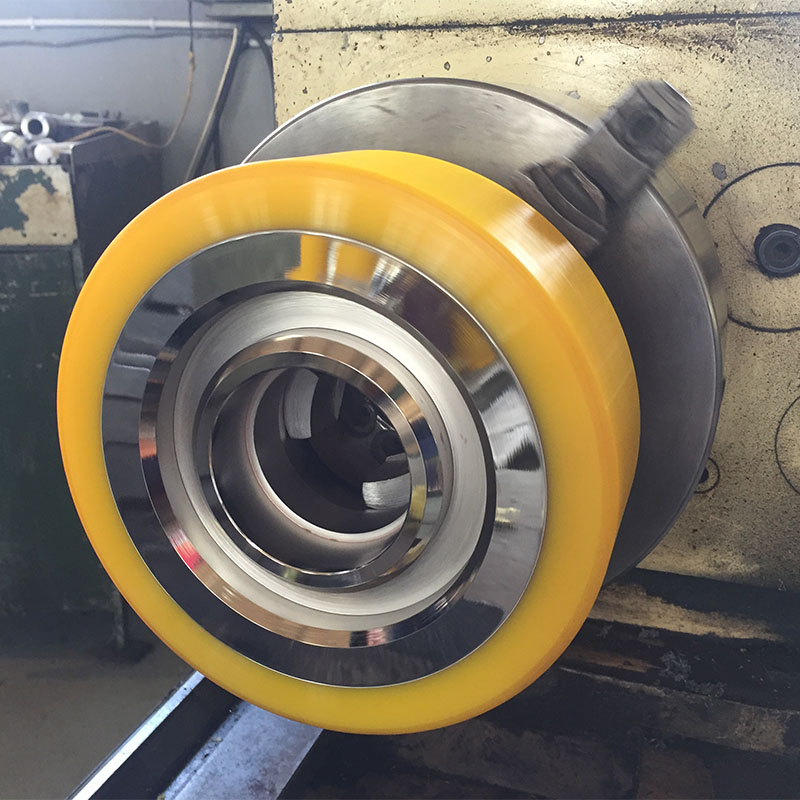

Railway transport wheel

-

Polyurethane threaded videos

-

T-shaped seal

-

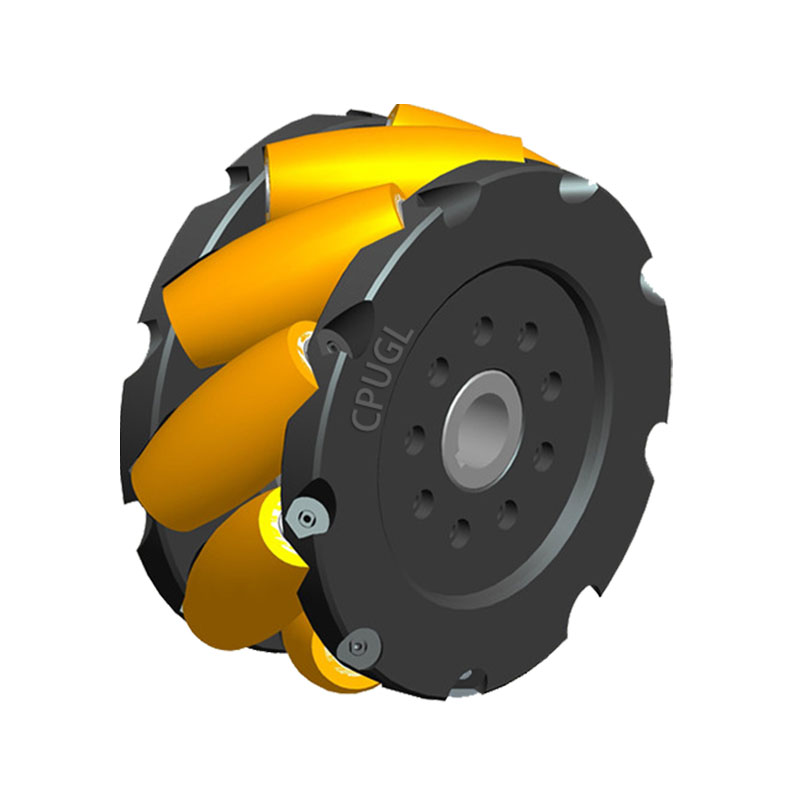

Wheels for robots

-

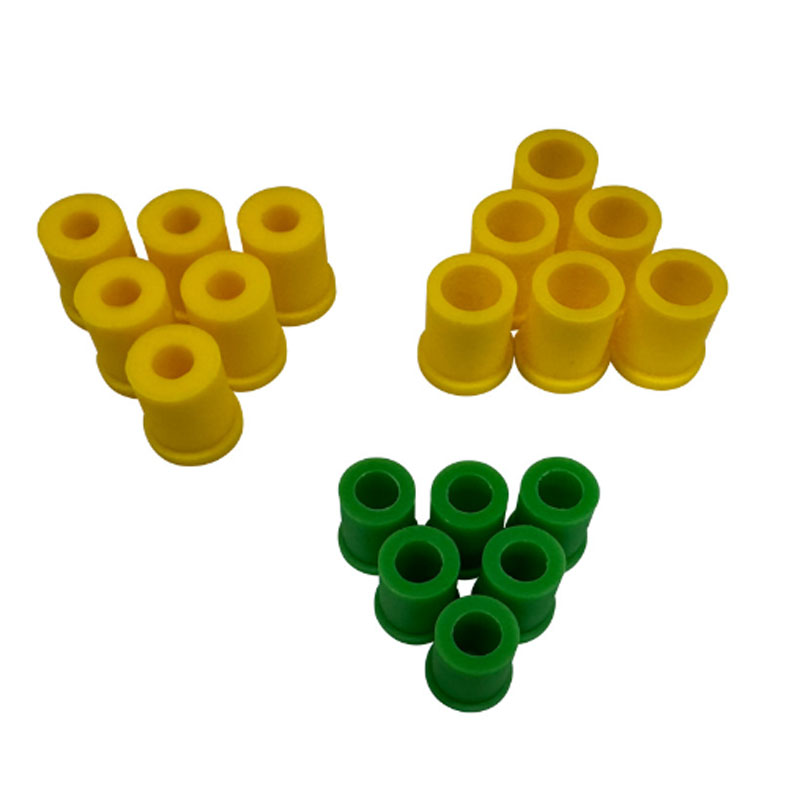

Sealing ring

-

Sealing tape

-

Polyurethane roller

-

Wheels for robots

-

The video of the conveyor tape

-

Type of fastening of the flange

-

Assault seal

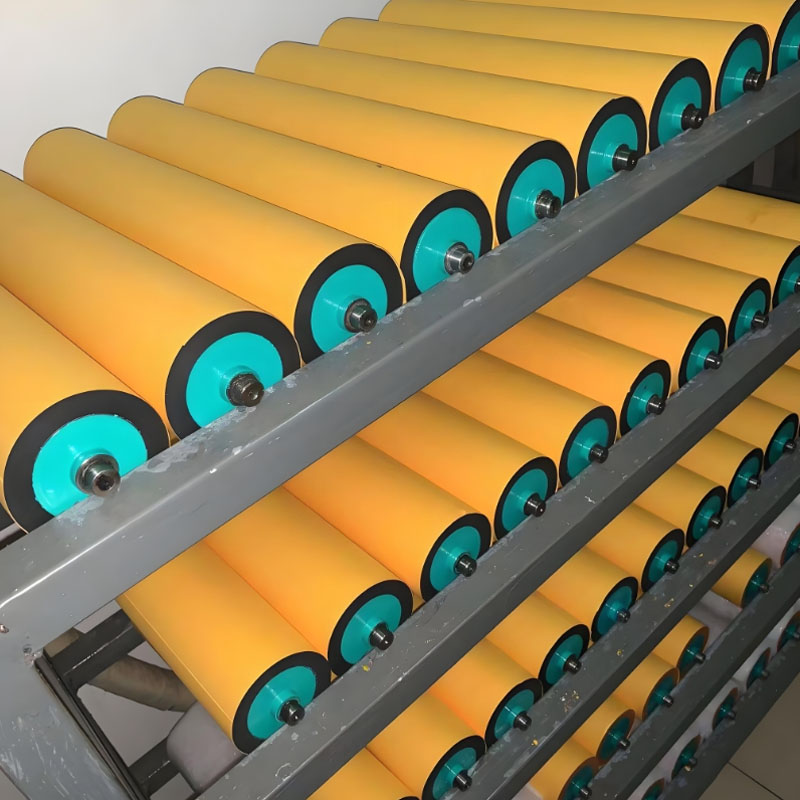

Polyurethane print shafts

A printed roller - a rubber roller used in printing equipment for printing, adjusting and transferring paint. Depending on the use of it, it can be divided into: ink roller, a roller for the distribution of ink, a clamping roller for paper, a roller for sucking paper, etc. ...

Description

marker

A printed roller is a rubber roller used in printing equipment for printing, adjusting and transferring paint. Depending on the use of it, it can be divided into: ink roller, an ink distribution roller, paper crush roller, paper suck, etc. colorful rollers are used to transport colorful coatings and require oil resistance, high elasticity and homogeneity of paint. The roller for the distribution of ink plays the role of mixing ink to make them homogeneous, and the rubber roller must have wear resistance, oil resistance, chemical resistance and high surface quality, and clamping paper troops are used to print on paper; It is understood that the suction roller is used to transport paper for printing. Polyurethane elastomer is a highly optically active polymer compound, which has a small affinity with neoptically active mineral oils and practically non -corroding in light fuel oils and mechanical lubricants.

Various printing requirements require different mechanical and chemical standards for rubber rollers. Excessive hardness can increase its corrosion resistance, but its ability to endure water and ink will decrease, and the breakdown of the printing machine and the wear of graphics and text in the PS version will increase. If the hardness is too small, the service life of a rubber roller can be too short due to poor resistance to pressure and corrosion. The range of polyurethane elastomers is the A10-D80 of the Schora.