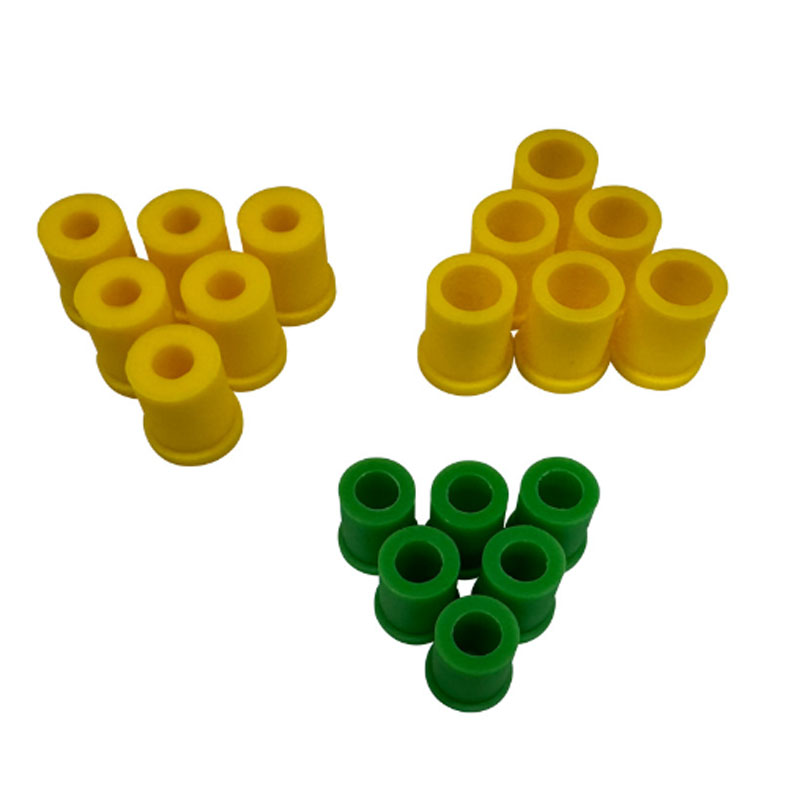

Polyurethane buffer springs

Polyurethane buffer springs

Polyurethane buffer springs are wonderful assistants in various mechanisms and systems. Imagine a soft, elastic pillow that can soften blows and vibrations. That's what, in fact, do these springs. They are used where smooth movement and protection against damage caused by sharp loads is important.

What are they and what are they used for?

Polyurethane is a special material that combines flexibility and strength. Boofer springs made from it are highly resistant to wear, the ability to absorb the energy of the blow and maintain their shape even with prolonged use. They are widely used in the automotive industry (for example, in suspension systems where they extinguish vibrations), in construction (for depreciation of structures and equipment), in household appliances (for example, in washing machines, where they provide a soft start and a drum stop) and even in sports goods (where they serve to protect). Simply put, they work as soft shock absorbers for different mechanisms.

Advantages of using polyurethane buffer springs

The main advantage is smoothness and safety. Polyurethane extinguishes the energy of the blows, preventing damage to the mechanisms and providing comfort in operation. In addition, they are usually durable and do not require frequent service. They are resistant to moisture, temperature changes and aggressive media, which makes them suitable for many conditions. Production from polyurethane allows you to get springs with various characteristics of stiffness and shape, which makes it possible to select the optimal solution for each specific task.

Disadvantages and restrictions

Like any material, polyurethane buffer springs have some restrictions. Despite the strength, they can be deformed at very large loads. Also, the choice of spring stiffness plays an important role, since too soft the spring cannot cope with the task, and too hard can create discomfort. Therefore, the correct selection depends on specific conditions of application. It is important to consider the loads, the frequency of work cycles and other factors to choose the best option.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

Polyurethane lining pipes

Polyurethane lining pipes -

Polyurethane vibration gaskets

Polyurethane vibration gaskets -

Bolt type of fastening

Bolt type of fastening -

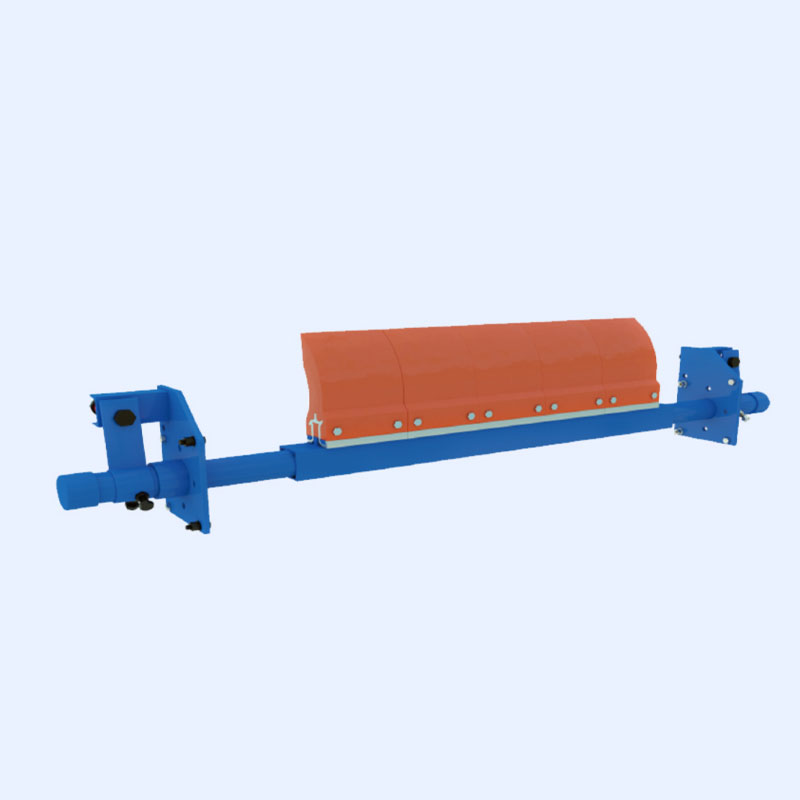

The video of the conveyor tape

The video of the conveyor tape -

Polyurethane buffer

Polyurethane buffer -

Highlighting cover

Highlighting cover -

Sealing tape

Sealing tape -

The video of the conveyor tape

The video of the conveyor tape -

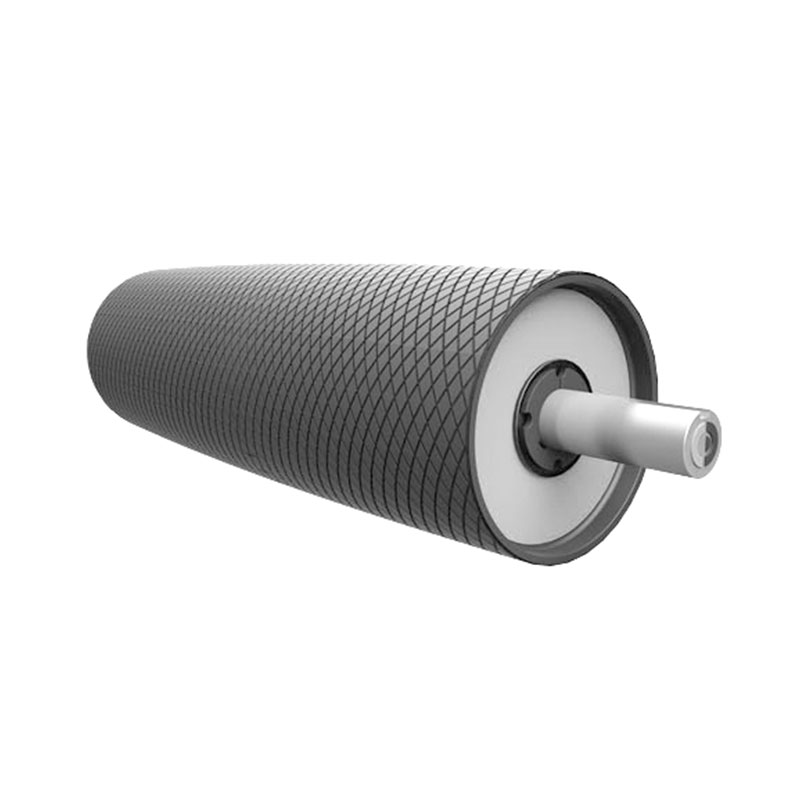

Polyurethane print shafts

Polyurethane print shafts -

Rounds for attractions and fitness equipment

Rounds for attractions and fitness equipment -

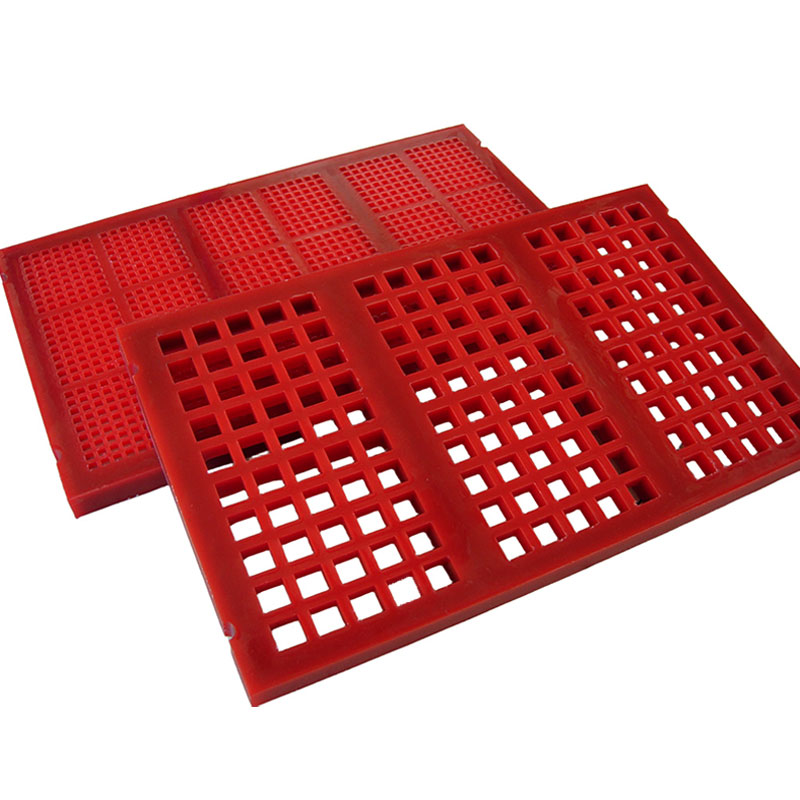

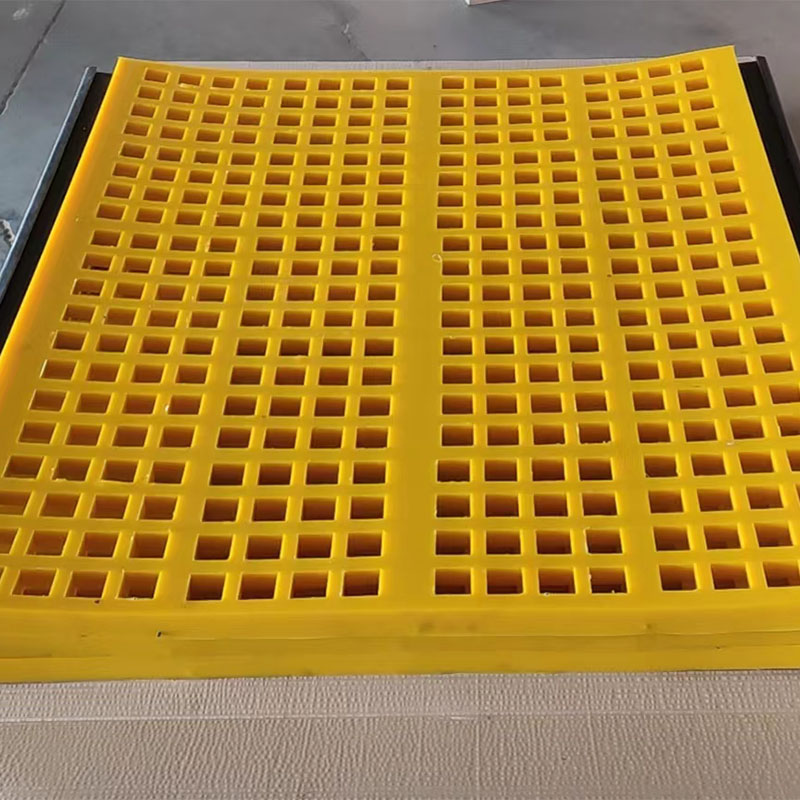

Sita mesh with tension

Sita mesh with tension -

Polyurethane rods

Polyurethane rods

Connectedsearch

Related search- All -lit wheel from polyurethane factory factory

- Rollers for conveyor tape Supplier

- Plants for the production of sealing rings in China

- Rubber Round Grounds Half Seal Manufacturer

- The best buyers of polyurethane V-shaped videos in China

- China of leading countries of the drive snowplifier of the pulleys

- Ring of the round section 6 factories in China

- Polyurethane sieve for roar supplier

- Chinese factories for the production of rubber round gaskets

- pulley