First -level conveyor tape

First -level conveyor tape

Conveyor tapes are an indispensable tool in various production processes. But, like any car, they need to care and maintain cleanliness. The cleaner of the first -level conveyor tape is an important component of this process. He works as a reliable assistant, helping to maintain the uninterrupted operation of the entire conveyor complex.

Functionality and principle of action

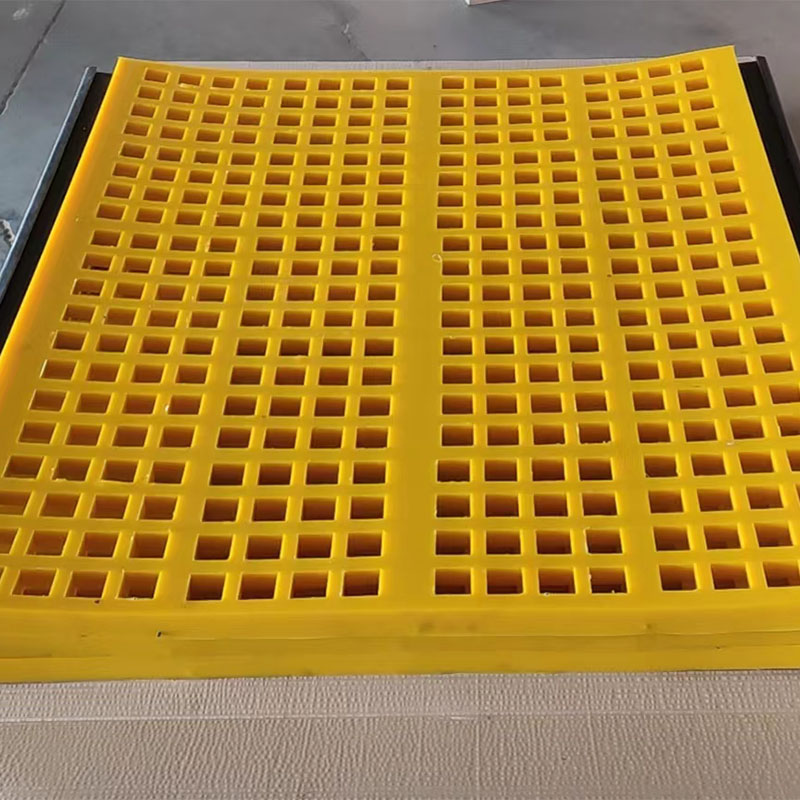

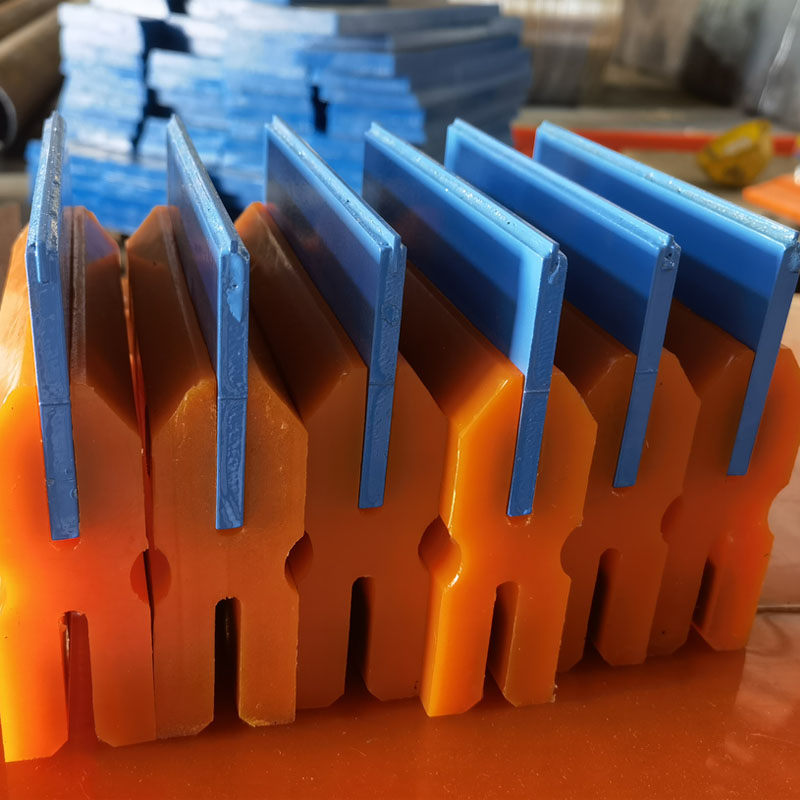

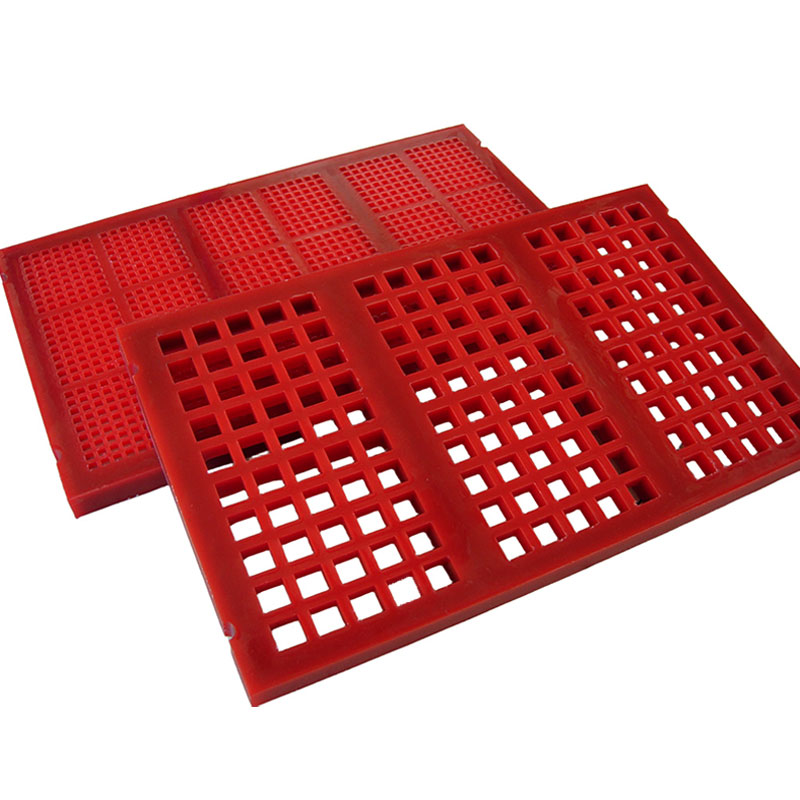

The main task of the cleaner is to remove various pollution from the tape: from small particles of dust to large waste. It can work differently, depending on the type of pollution and materials that the conveyor transports. Often this occurs through mechanical scraper or pneumatic effects that separates unnecessary elements from the tape. Imagine that the tape passes through a kind of sink - this is, in a simplified sense, the principle of action of the cleaner.

Advantages of use

The use of the first -level cleaner brings tangible advantages. Firstly, this is the preservation of the quality of the product. The absence of extraneous particles on the tape prevents pollution of the processed materials, which guarantees their quality. Secondly, this increases the productivity of the conveyor line. The lack of obstacles in the form of garbage and pollution contributes to faster and more effective transportation. And finally, this extends the service life of the conveyor tape itself. Regular cleaning prevents the accumulation of pollution that could damage its structure. As a result, we get saving resources and time, and also avoid possible stops of the conveyor.

Choice and installation

The choice of a specific cleaner depends on the features of the conveyor tape, the type of transported materials and production tasks. It is important to take into account the technical characteristics of the cleaner and its compatibility with other components of the conveyor. For successful work, high -quality design and installation is necessary. The correct installation of the cleaner guarantees that it performs its function without problems and as efficiently as possible. As a result, a competent selection and installation of the cleaner is the key to uninterrupted and high -quality work of the entire production.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- spaces for springs to increase clearance

- Rod filters factories in China

- Cultivator pulley

- Spring spacer

- Supply a safety wheel supplier

- Front springs of the Niva

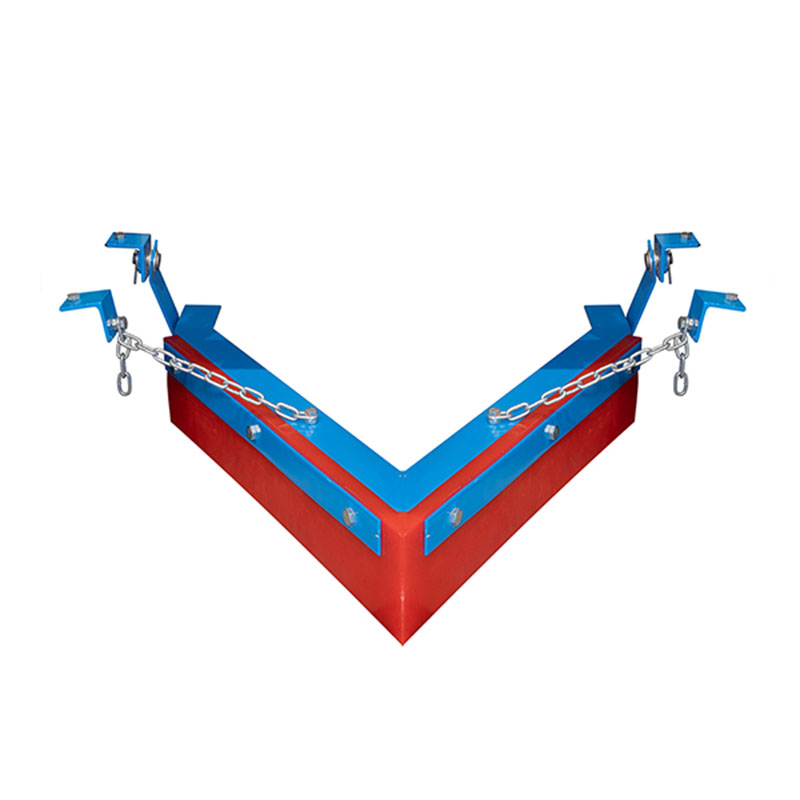

- Cleaner of the ribbon conveyor of the return empty section of the V-shaped wholesale

- Manufacturers of spring goals kia in China

- polyurethane wheel with a bearing manufacturer

- Prices for polyurethane buffers for cranes in China