axes for polyurethane wheels

Axes for polyurethane wheels: choice and application

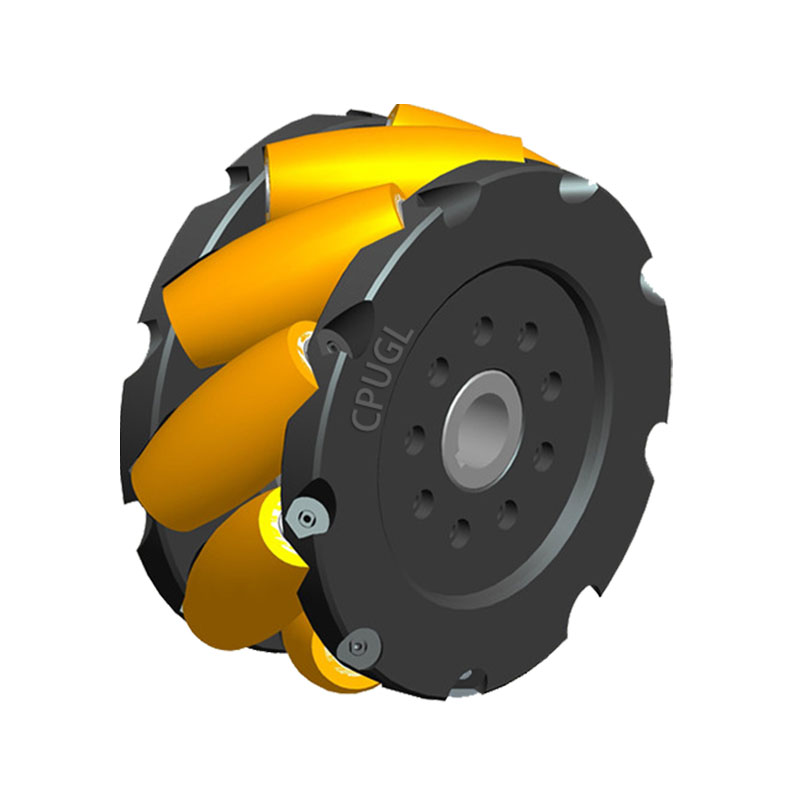

Polyurethane wheels are an indispensable element in various fields, from industrial equipment to children's toys. But in order for these wheels to function effectively and for a long time, it is extremely important to choose the right and install the axis. Let's figure out what you need to pay attention to when choosing.

Oses materials

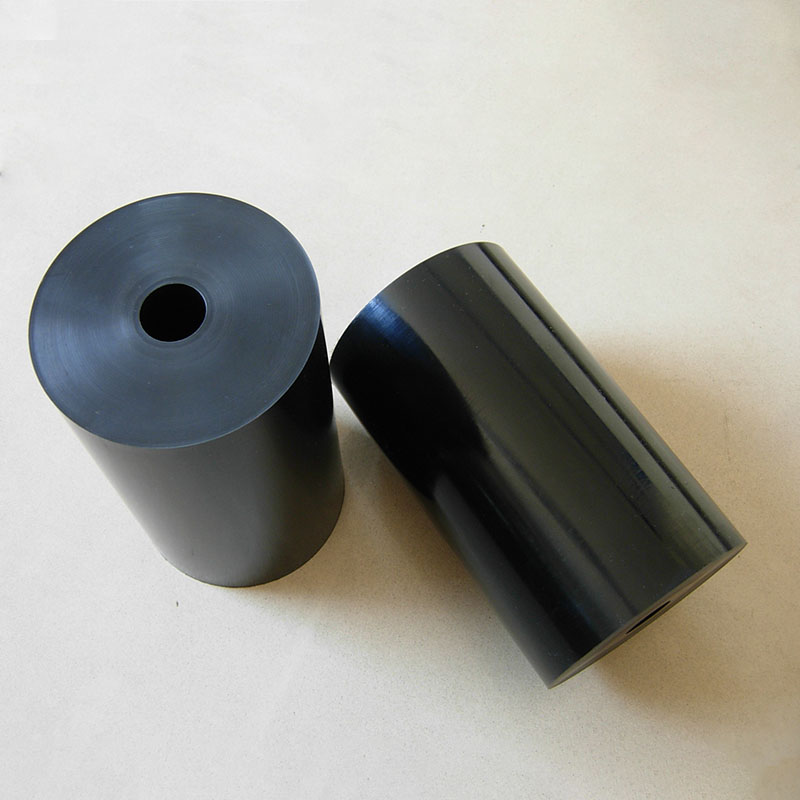

The quality of the axis directly affects the life of the entire product. The most common materials for the axes of polyurethane wheels are steel, stainless steel and aluminum. Steel is a strong and reliable option, but heavy. Stainless steel, as the name implies, is resistant to corrosion, which makes it preferable for use in moist conditions. Aluminum, although easier, can be less durable than steel. The choice depends on the specific task and the alleged loads. For example, an aluminum axis is quite suitable for light baby strollers, and for industrial equipment - steel.

Oses characteristics

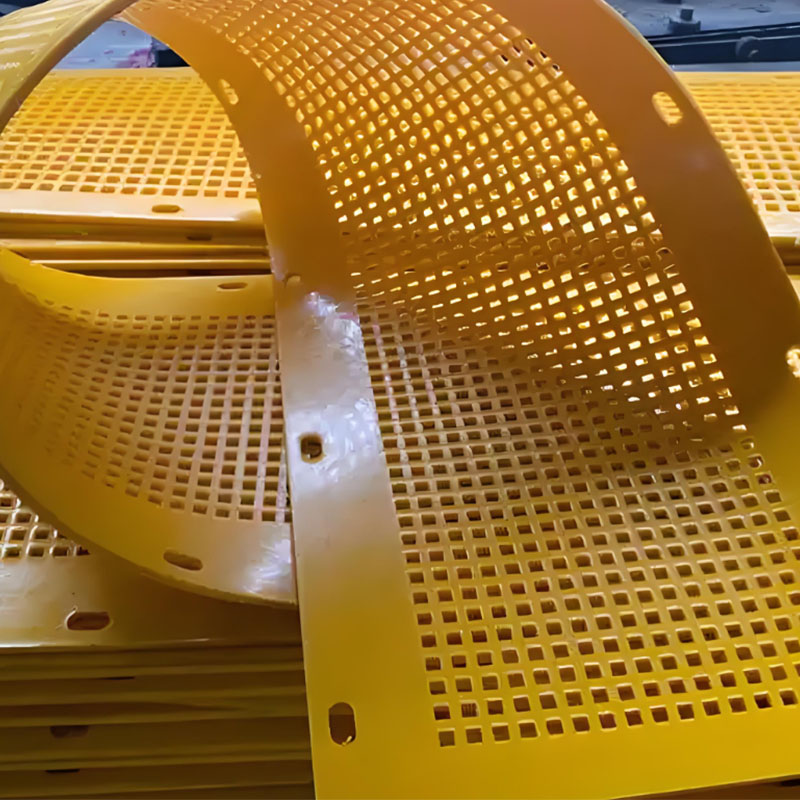

It is important to consider not only the material, but also the geometric sizes of the axis. Diameter and thickness are important for ensuring strength and resistance to bending and twisting. An incorrectly selected diameter can lead to premature wear of both the axis and the wheels. You also need to pay attention to the type of connection of the axis with the wheel - it can be a key, thread or another type of connection, which will provide reliable fixation. Check that this connection corresponds to your equipment and the alleged load. The way of attaching the axes to the main design is also important - it should be such as to guarantee stability and prevent spontaneous movement during operation.

Selection of axes for specific tasks

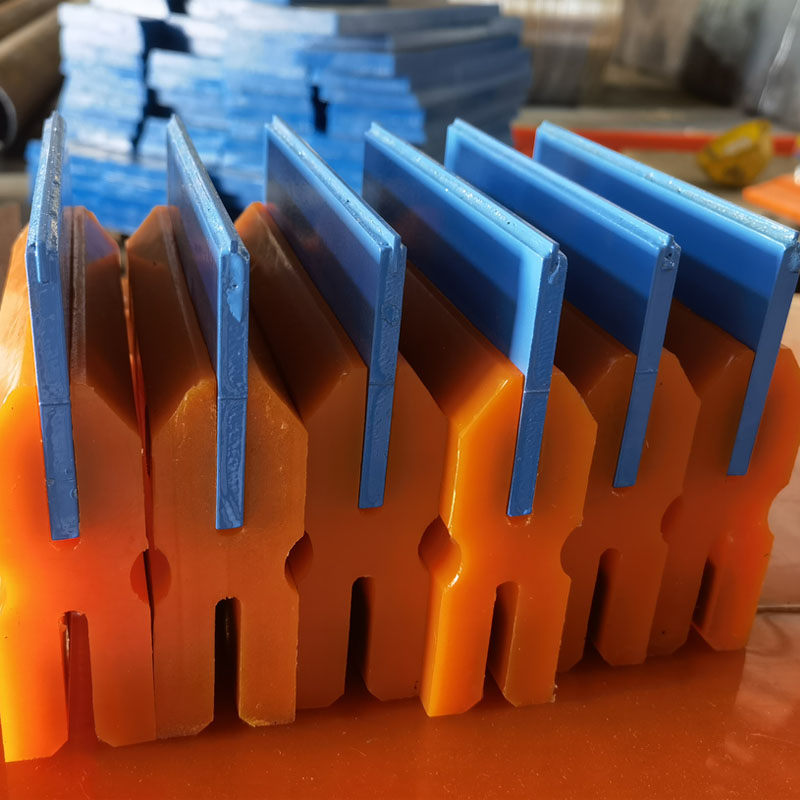

The correct selection of the axis is not just a matter of choice of material. Each case needs an individual approach. For example, the axis for a toy machine should be light and strong to withstand small loads. At the same time, the axis for the conveyor tape should be much stronger, can withstand significant loads, and be resistant to vibration. In any case, before buying, be sure to take into account the maximum carrying capacity, type of material, and the characteristics of the alleged working conditions. Only in this way can you ensure the durability and reliability of your equipment.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Suppliers of stands in China

- U-shaped seal factory

- Polyurethane videos

- Suppliers of sealing gaskets in China

- Vedic pulley of the rele of an eye in China

- Prices for polyurethane spiral videos in China

- Rubber Round Grounds

- Prices for polyurethane blades from China

- Leading buyer of polyurethane drums in China

- The price of the production of conveyor rollers in China