Service ring 4

Service ring 4

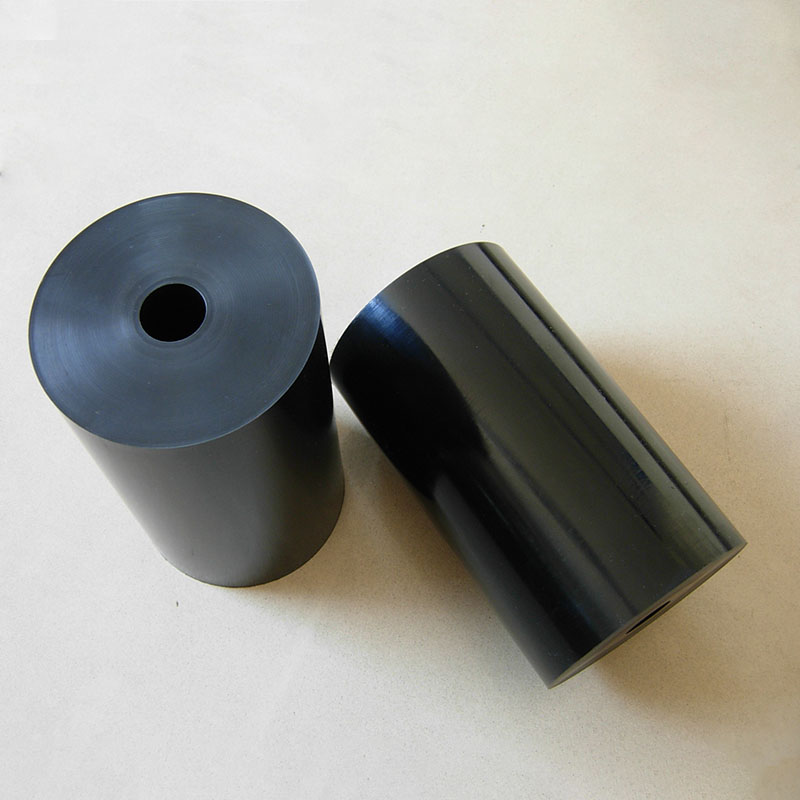

Sealing rings - inconspicuous, but very important details in a variety of mechanisms. Imagine that you are trying to close the gap between the two parts so that any liquid or gas does not flow. The sealing ring 4 is like a small but reliable hero who stands on the guard of tightness.

Types and materials

The sealing ring 4 can be of different sizes, shapes and made from various materials. For example, silicone rings are good for working with chemically active environments, and fluoroplastic ones for high -temperature applications. Metal rings - for more stringent conditions. The choice of material depends on a specific task: does the seal need when working with water, oil, gas or chemicals? It is important to take into account how aggressive the environment will be, at what temperatures the design will work and what level of pressure needs to be kept.

Installation and application

The correct installation of the ring is the key to its effective work. An incorrectly inserted ring may not provide the proper seal and lead to leaks. It is important to follow the manufacturer's instructions, especially when using special tools. The sealing ring 4 can be used in pumps, compressors, reinforcement and much more. Imagine how important it is that the liquid does not proceed, for example, from the pipe, or so that the pressure in the system works stably. In each of these examples, the ring plays an important role.

Care and service life

To extend the service life of the ring, it is important to monitor the cleanliness of the working environment and observe temperature conditions. Periodic check for damage and replacement if necessary - a guarantee of long and uninterrupted work. If the sealing ring is exposed to strong exposure or abrasives, its service life can be reduced. Understanding the characteristics of the material and operating conditions helps to optimally choose and use the sealing ring 4 to achieve maximum efficiency and durability.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- The main suppliers of sealing rings 8 from China

- polyurethane wheel with a bearing in bulk

- Suppliers Silicone sealing gaskets in China

- Chinese suppliers of conveyor videos Moscow

- Half -laying for the toilet toilet in bulk

- Wheels for a car Polyurethane sound factory

- Rubber shaft factories in China

- The best countries-buyers of whole polyurethane wheels for single-wheeled bicycles in China

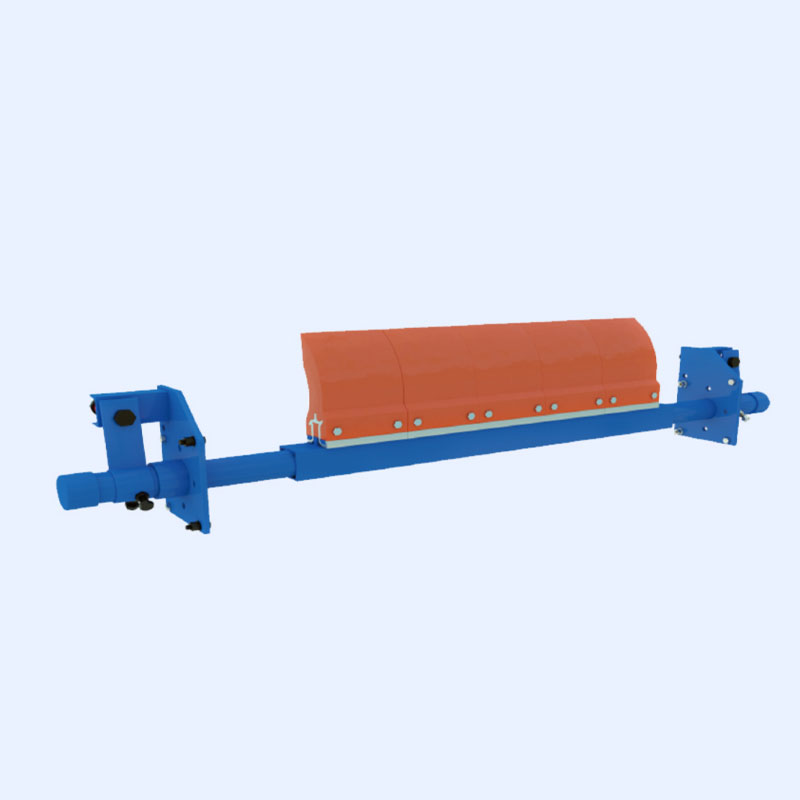

- Use cleaning device manufacturer

- Wheel for a car Polyurethane all -liter buy in China