Ring seals

Ring seals

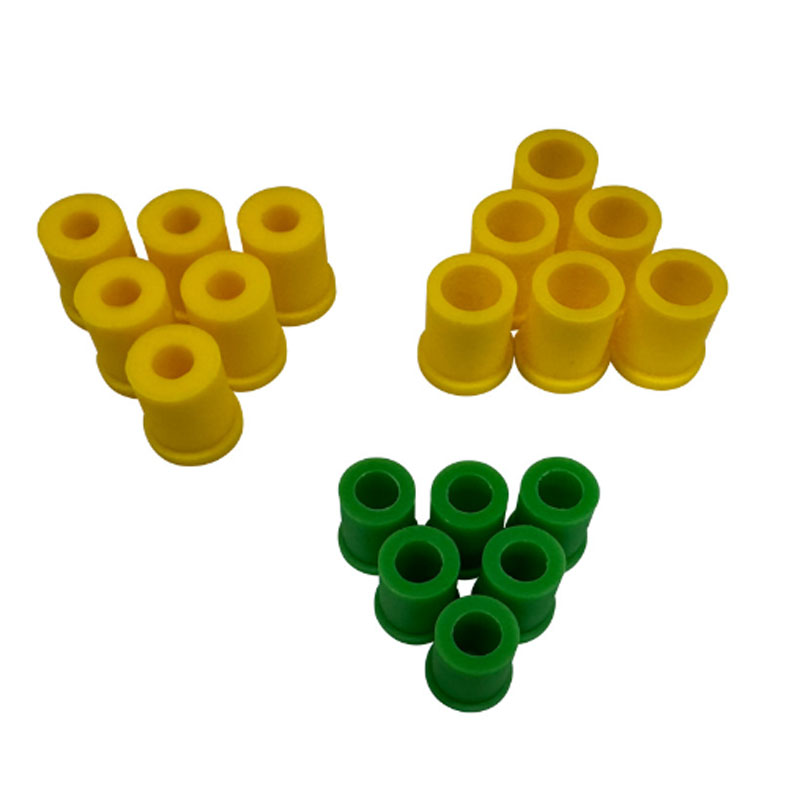

Ring seals are indispensable assistants in many mechanisms that surround us. Imagine that you need to close the gap between two parts to prevent a leakage of liquid or gas. It is here that these small but strong assistants come to the rescue.

Varieties and materials

There are many types of ring seals, each of which is suitable for certain tasks. From simple rubber rings to complex metal products, the choice depends on the working conditions. For example, for work in aggressive media (for example, chemical solvents), seals from special, resistant to corrosion of materials are used. For high temperatures - from heat -resistant alloys. Some seals are made of materials that flexibly adapt to the shape of the surface, others are strict, providing dense fit. When choosing a seal, it is important to consider not only the material, but also the size, shape and accurate correspondence to prevent leaks. Unfortunately, the wrong choice can lead to trouble.

Role in everyday life

Ring seals are indispensable in various fields. Imagine your refrigerator: they hold the cold inside and prevent it from leaving. In cars - they prevent leakage of oil and coolant. In pumps and compressors - they provide reliable tightness, preventing the working substance. Even in your computer, in complex ventilation and cooling systems where you need to maintain tightness, seals are used. Without them, many devices simply would not work.

How to choose the right seal

When choosing a suitable ring seal, several key factors must be taken into account. First of all, this is an environment in which the seal will work: temperature, pressure, chemical composition. Next, you should pay attention to the shape and size. Correctly selected seal is a guarantee of reliable and long operation of the mechanism. Feel free to contact specialists if you do not understand the subtleties of choice, because the wrong choice can lead to expensive problems and breakdowns. It is important to consider all conditions and details.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Suppliers PRP sealing from China

- Chinese suppliers of seals for mixers

- Suppliers Seal gasket PRP diameter 30 mm from China

- Chinese manufacturers of large drive pulleys

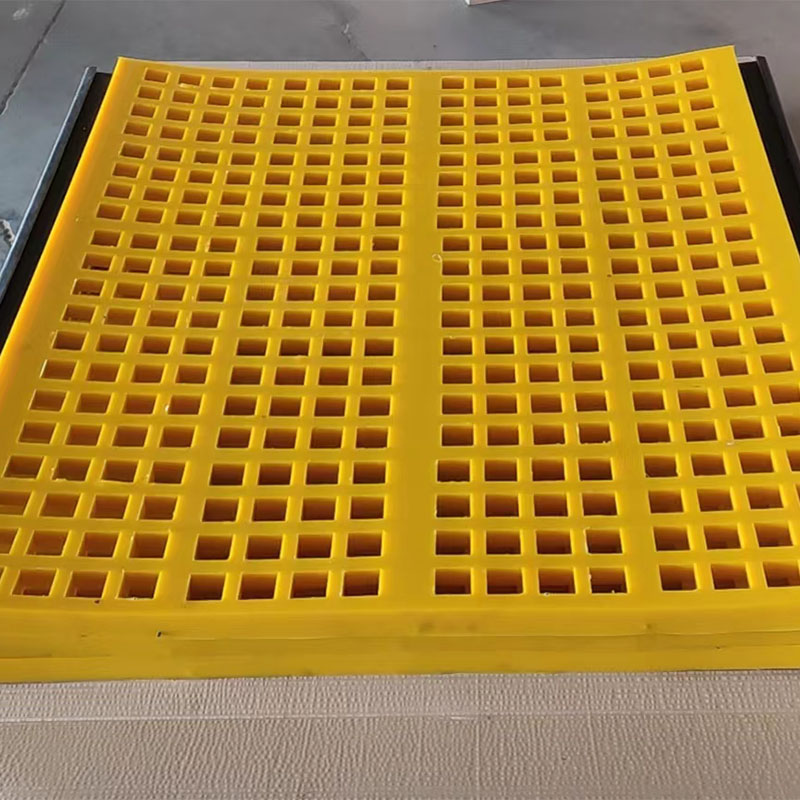

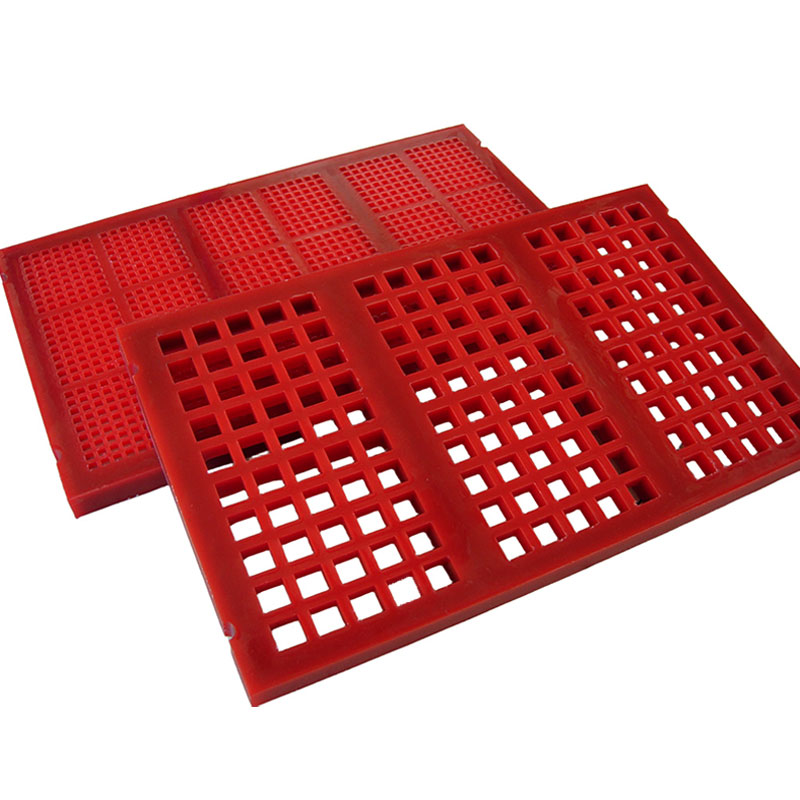

- Chinese producers of polyurethane sieves for roar

- Polyurethane sieve manufacturers in China

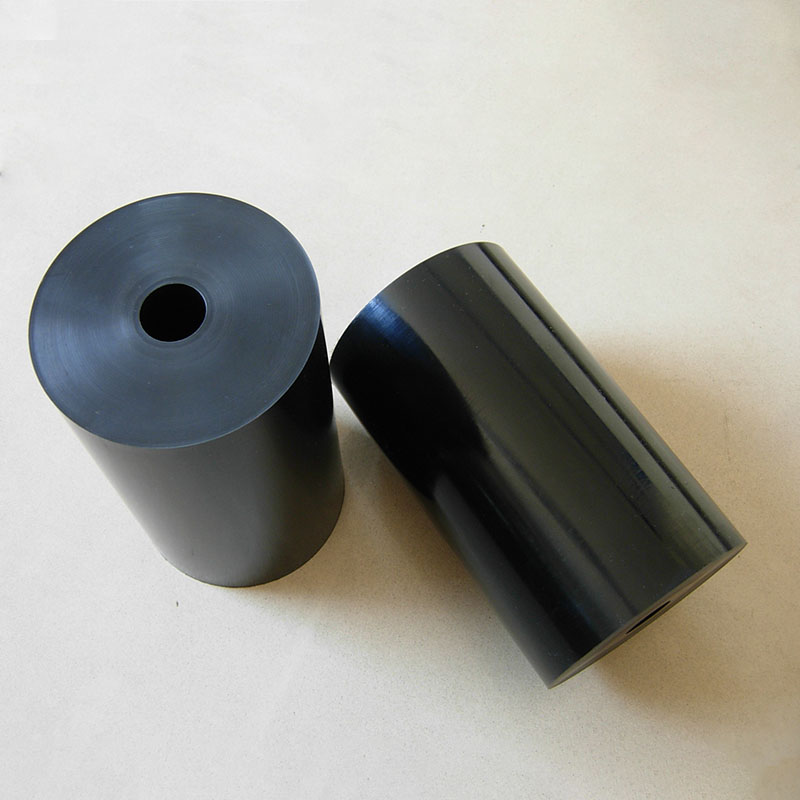

- The best suppliers of polyurethane rods from China

- Suppliers of the production of conveyor rollers in China

- Ward wheels from China

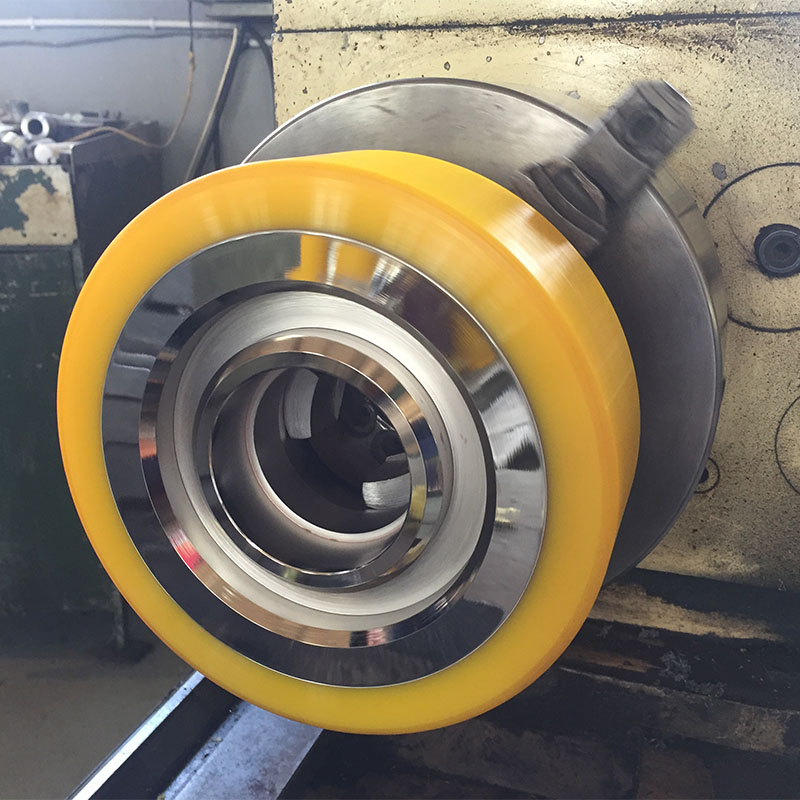

- polyurethane wheel with a bearing in bulk