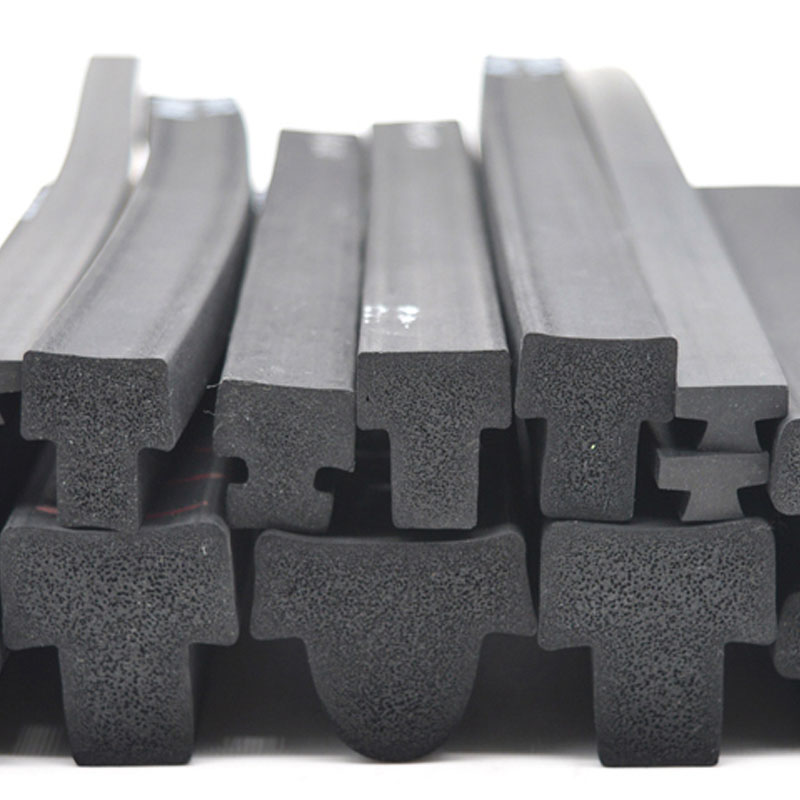

The rings are sealing oil

Highlighting rings: a reliable heart of your technique

Oil sealing rings are inconspicuous, but extremely important details that play a decisive role in the work of many mechanisms. Imagine them as small, but powerful guards that prevent oil leaks and providing a long life of your technique. They are like an invisible obstacle that protects against losses of a valuable resource - oil, which is vital for the lubrication and cooling of moving parts.

Types of oil sealing rings

There are many types of oil rings, each of which is designed for certain tasks. Some rings are ideal for work in high temperatures, others for complex loads. The choice depends on the features of a particular machine. There are rings with various forms and materials that affect their resistance to wear and ability to withstand high pressure. Understanding these differences will help you choose the right ring for your task. Different rings can have different thicknesses, diameter and material, allowing you to choose the most effective solution for the specifics of your technique.

How to choose the right oil sealing rings

When choosing oil rings, it is important to consider several key factors. First of all, pay attention to the diameter of the shaft on which the ring is installed. An incorrectly selected ring will not be effectively compacted and can cause leaks. An important factor is also the operating temperature and pressure. Choose the material of the ring corresponding to these parameters so that it does not deform and does not collapse. Do not forget about the lubricants that will be used in your system. It is important that it is compatible with the material of the ring.

Care and replacement of oil sealing rings

Regular inspection and timely replacement of worn or damaged rings is the key to the long and uninterrupted operation of your technique. Do not neglect this, because the loss of oil can lead to expensive breakdowns and simple equipment. Pay attention to any visible damage: cracks, deformation or unevenness. If you notice signs of wear, immediately replace the ring. Also, when working with equipment, always follow the manufacturer's instructions to avoid possible damage. This will help save your equipment in excellent condition and save money on repairs.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Manufacturers of sealing caps in China

- The main countries of the departure of caterpillar wheels from China

- The pulley of the snowman is driven

- conveyor rollers supplier

- Leading buyers of cushioning materials from China

- front springs

- spacers under the Niva springs

- Chinese factories for the production of drive rollers for conveyors

- Cleaner of the ribbon conveyor of the return, empty section of the V-shaped in China

- Polyurethane scraps for conveyor tapes in China