Products

-

Sealing ring

-

Polyurethane shaped details

-

Rounds for attractions and fitness equipment

-

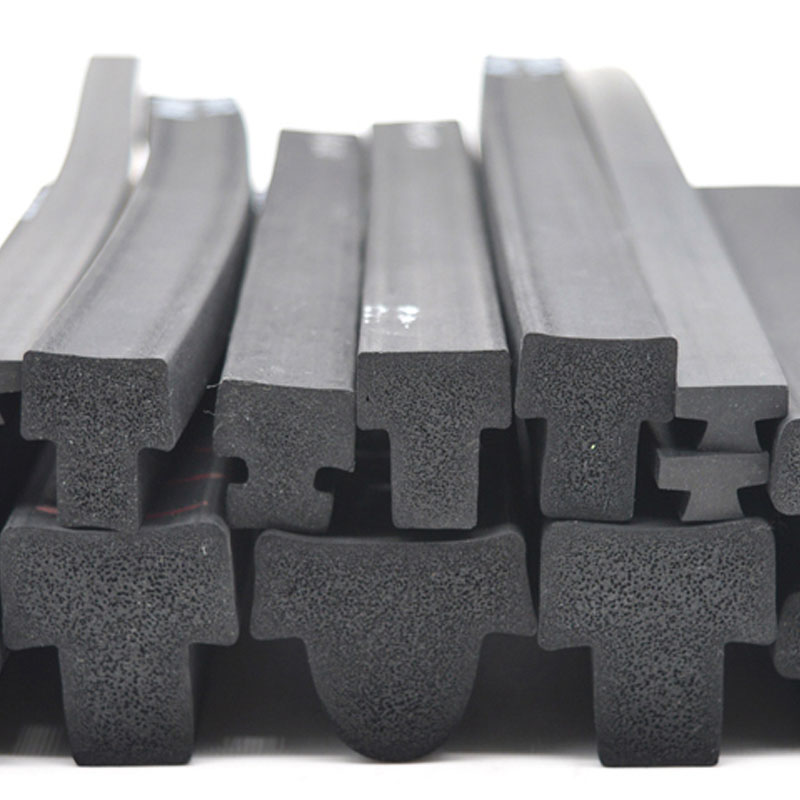

T-shaped seal

-

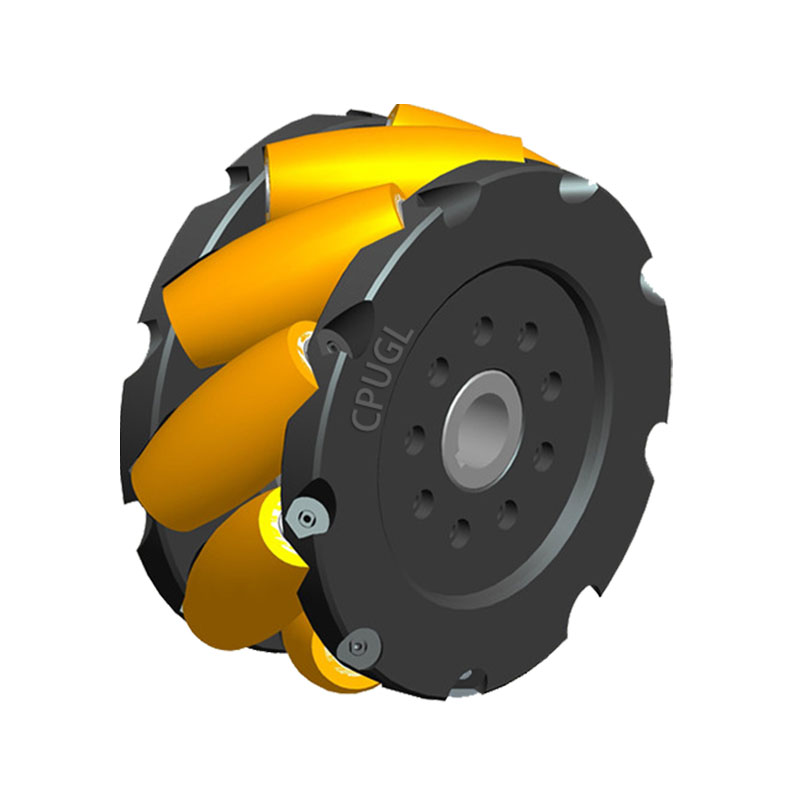

Wheels for robots

-

The video of the conveyor tape

-

Polyurethane V-shaped video

-

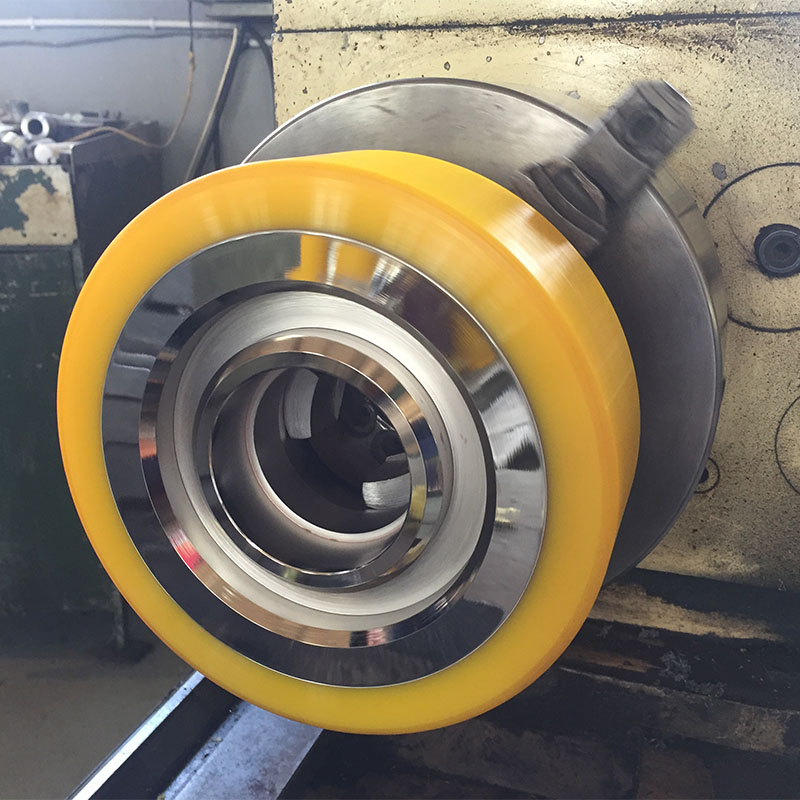

Railway transport wheel

-

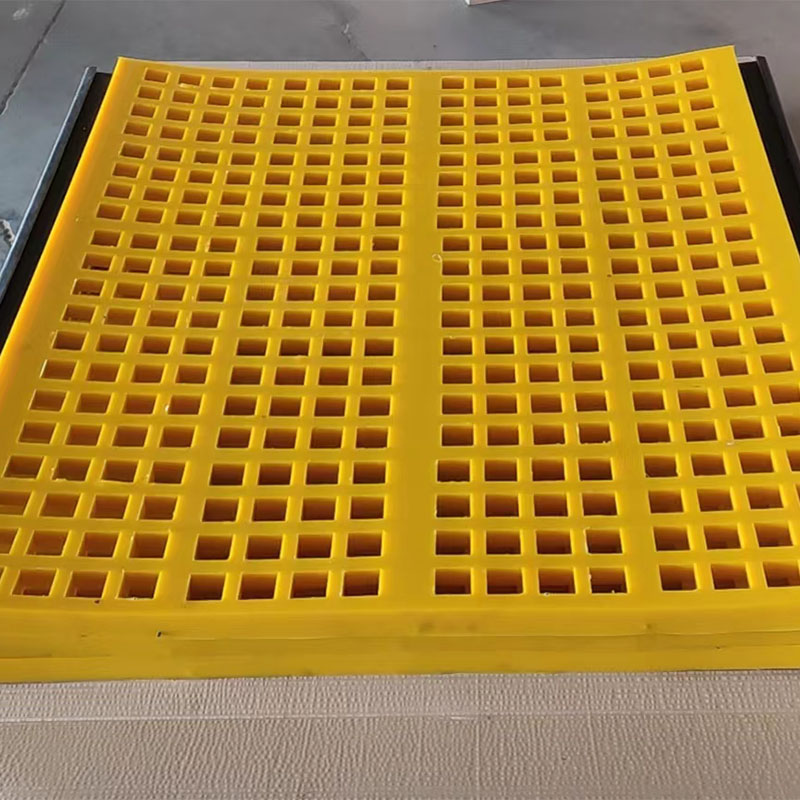

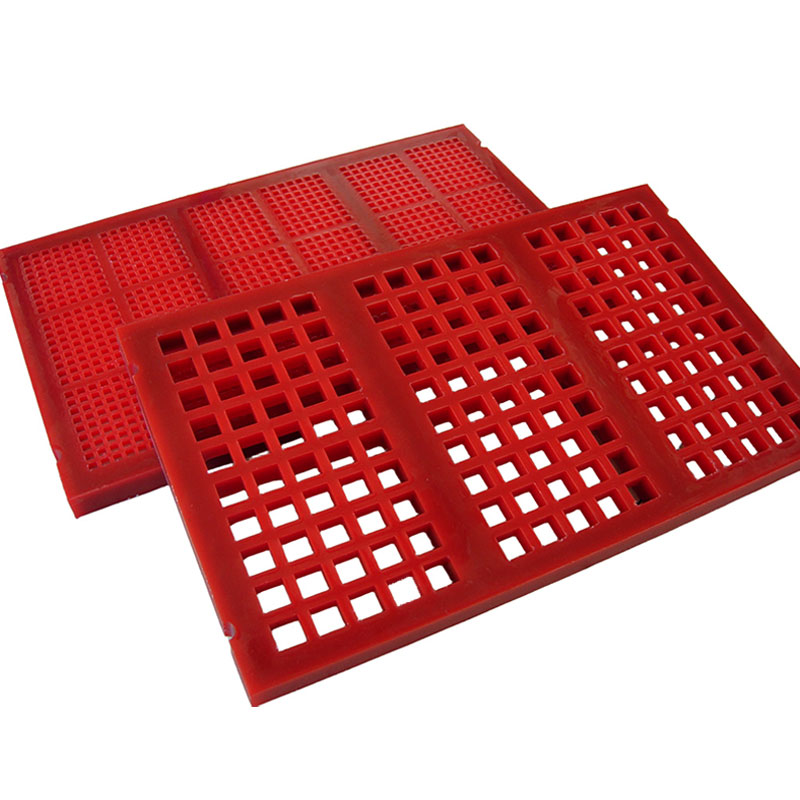

Sita mesh with tension

-

Highlighting cover

-

Polyurethane sieve for roar

-

A sealed plug

-

Type of fastening of the flange

-

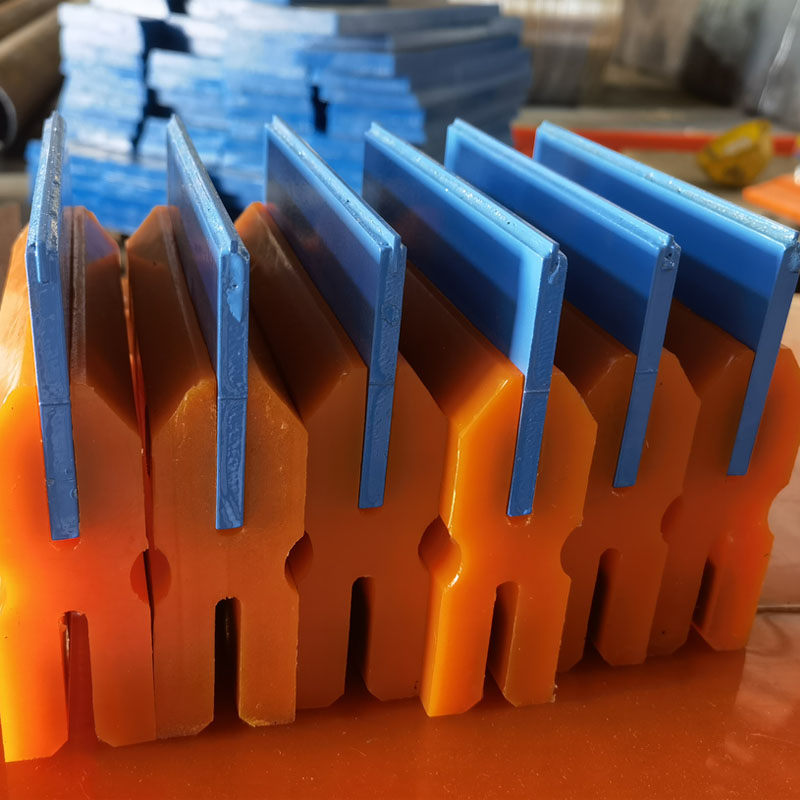

Polyurethane scraper

-

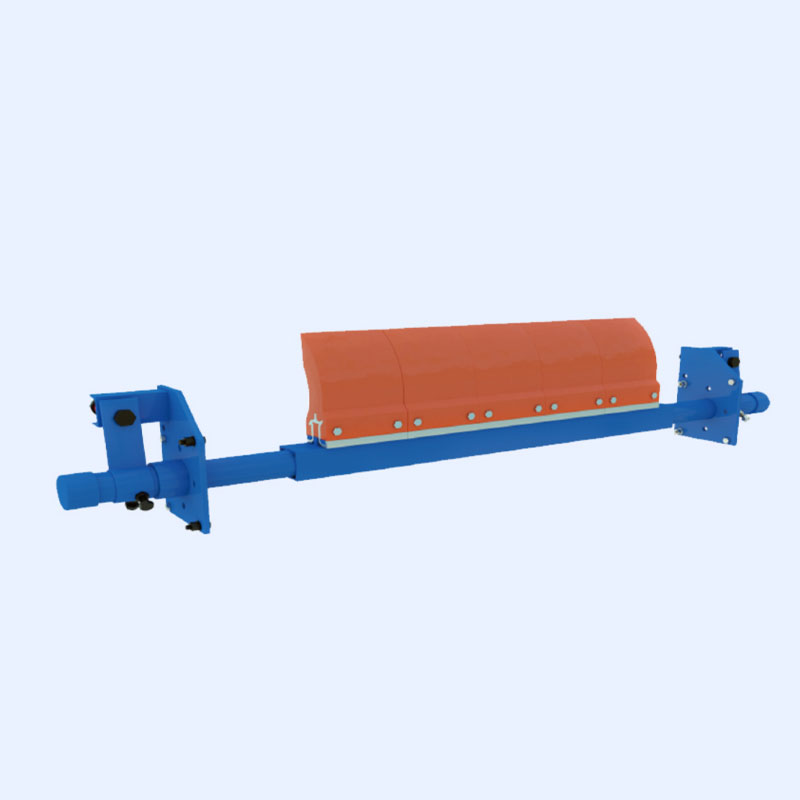

Polyurethane Otteral machine

-

U-shaped seal

Wheels for robots

With the continuous progress of industrial technologies and a change in market demand, the use of polyurethane wheels in the robotics industry will expand. Polyurethane balancing wheels, drive wheels, load -bearing wheels and running wheels for robots are easily deformed and possessed ...

Description

marker

With the continuous progress of industrial technologies and a change in market demand, the use of polyurethane wheels in the robotics industry will expand. Polyurethane balancing wheels, drive wheels, carrying wheels and running wheels for robots are easily deformed and have excellent noise -disposable characteristics during prolonged movement with high load.

1, resistance to abrasion: polyurethane materials have excellent abrasion resistance, which makes polyurethane drive wheels for a long period of time, high -intensity use in the process can maintain a low wear level to extend the service life.

2, elasticity and elasticity: polyurethane materials have excellent elasticity and elasticity. Thanks to this characteristic, the polyurethane drive wheel during impact or compression can be quickly restored to the original shape, energy losses and vibration transmission are reduced, and the smoothness of the work and the effectiveness of the equipment are increased.

3, corrosion resistance: polyurethane materials have good resistance to various lubricants, solvents and chemicals, can maintain stable work in complex, harsh working conditions, such as chemicals, solvents and even water.

4, low noise: low noise characteristics of polyurethane material make polyurethane drive wheels in the process of work produce low noise level, help improve the working environment, reduce noise pollution.

5, Setting: Polyurethane drive wheels can be configured in accordance with the requirements of the customer, such as antistatic, adsorption, greater friction and other characteristics to satisfy various environment and work requirements.