Products

-

Sealing gasket

-

C-shaped seal

-

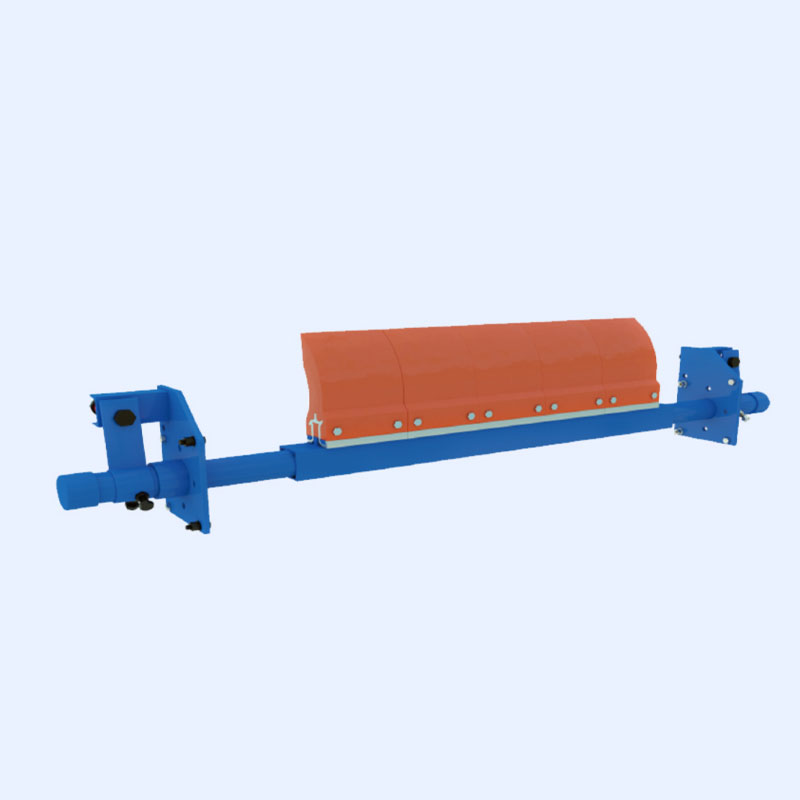

Polyurethane Otteral machine

-

O-shaped seal

-

The video of the conveyor tape

-

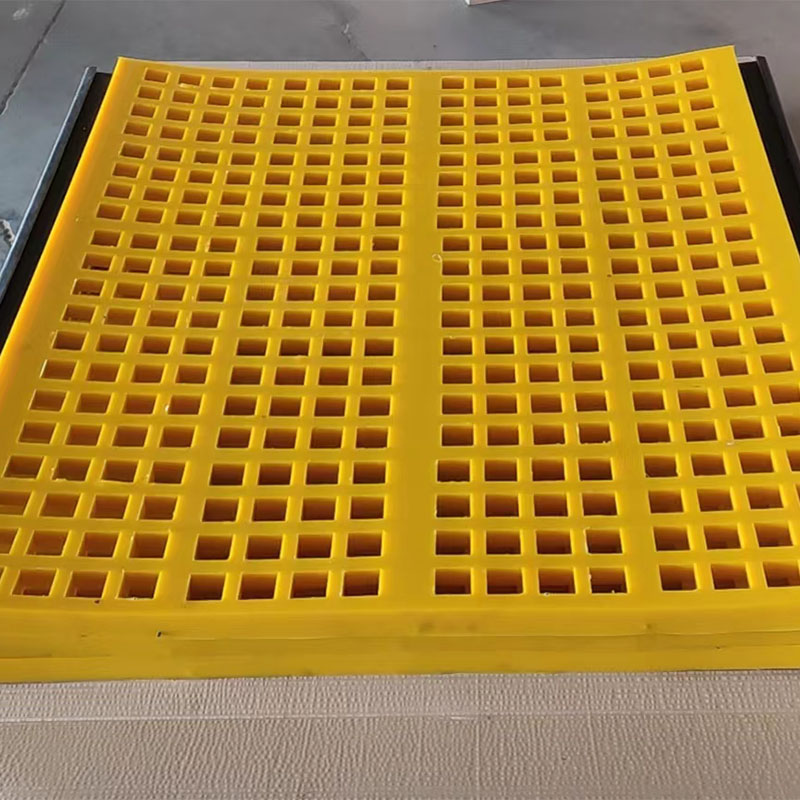

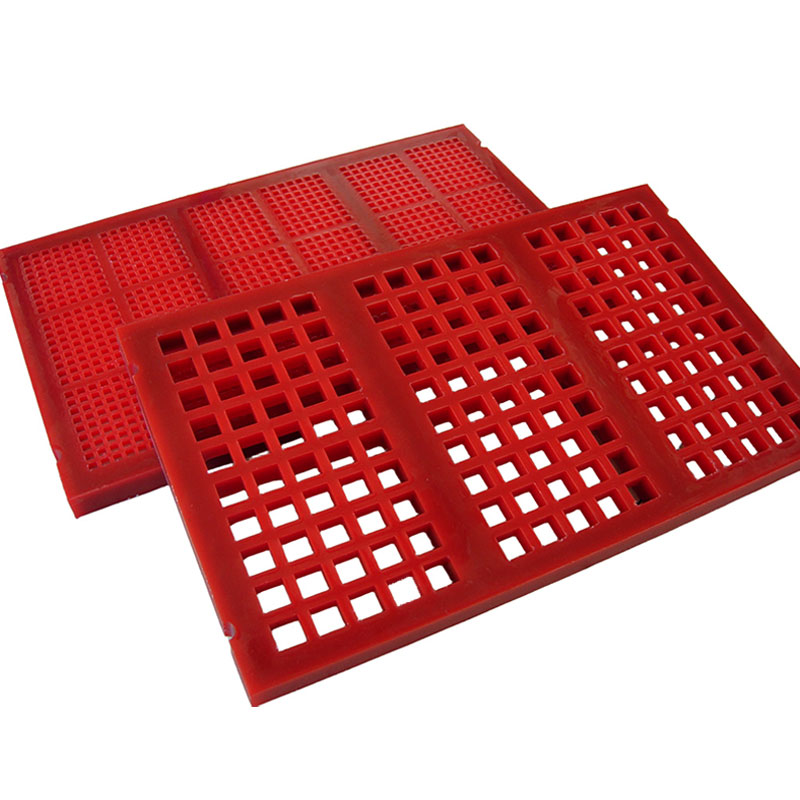

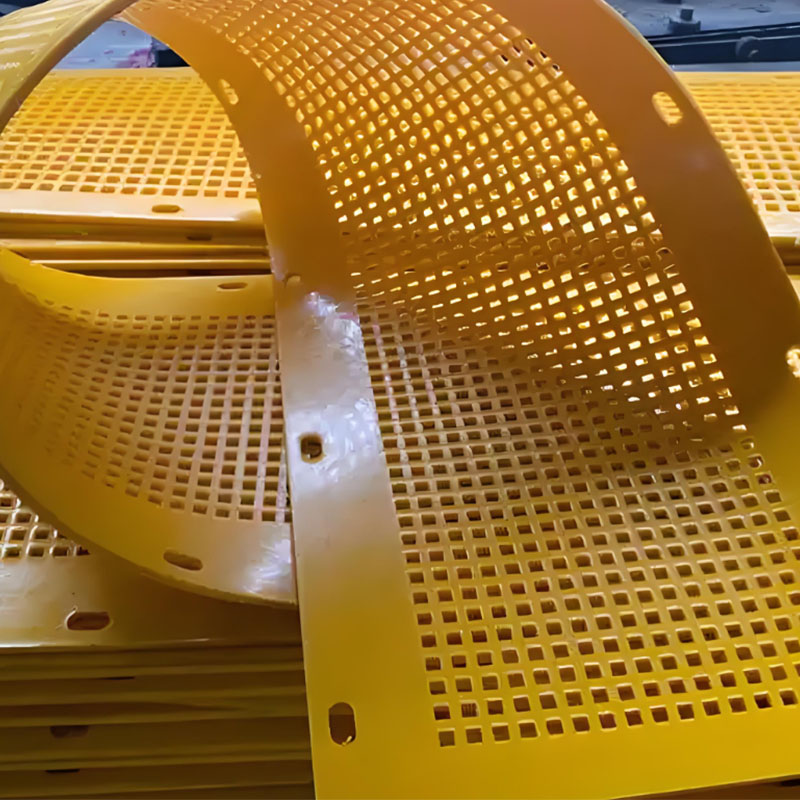

Polyurethane sieve for roar

-

Sealing ring

-

Railway transport wheel

-

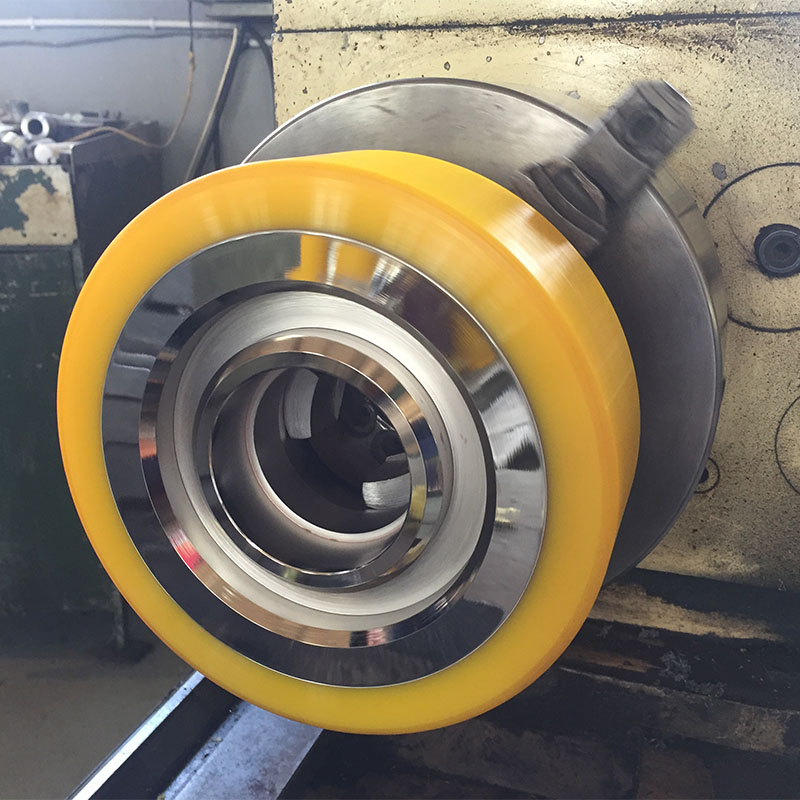

Heavy wheel

-

Polyurethane print shafts

-

Sita for the roar of polyurethane

-

Polyurethane buffer

-

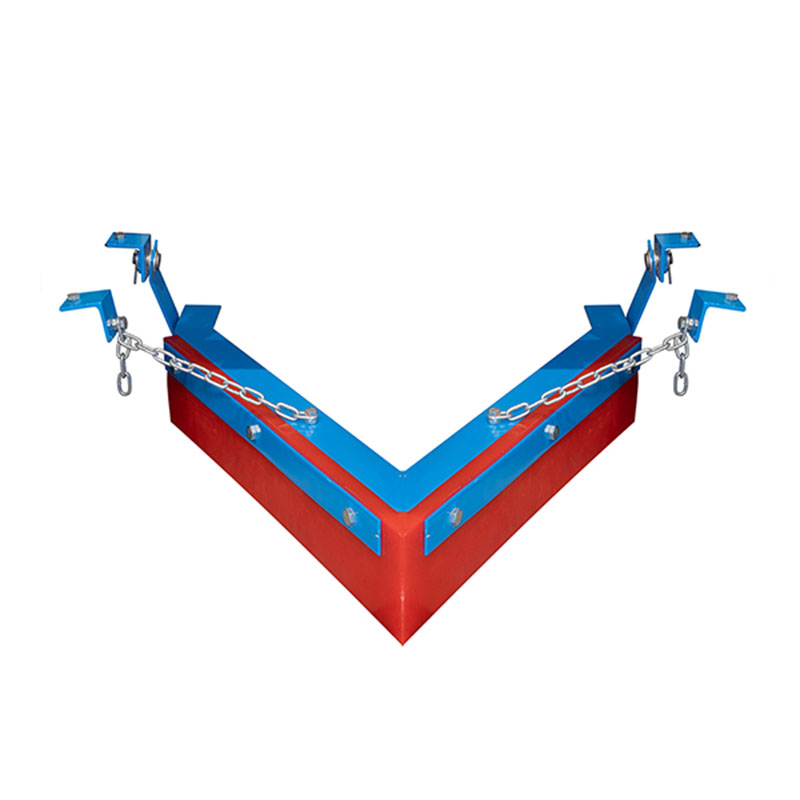

Polyurethane barrier from collisions

-

Drum screen

-

Polyurethane lining pipes

-

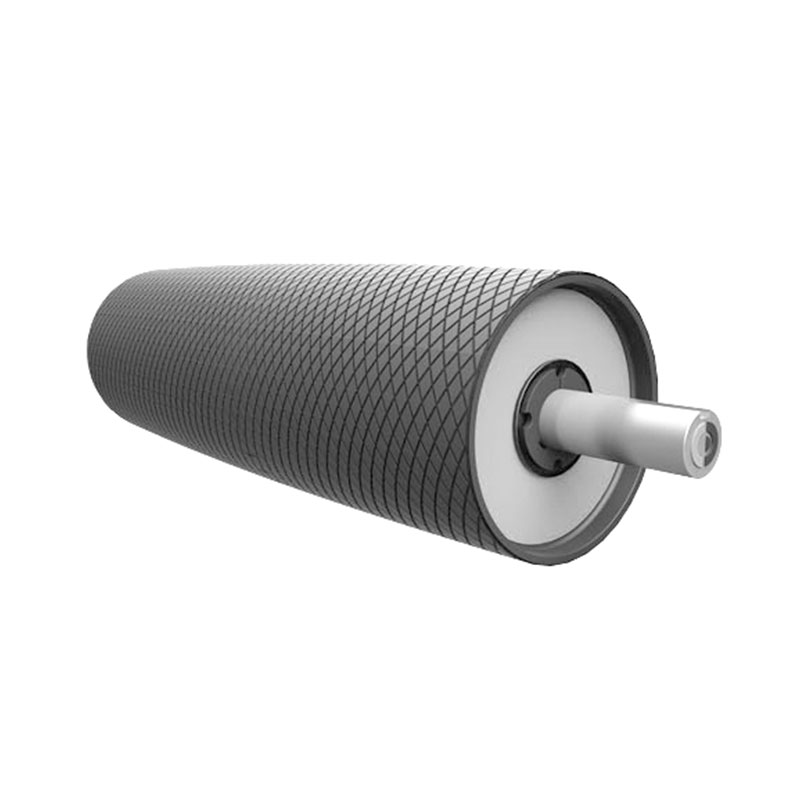

Polyurethane roller

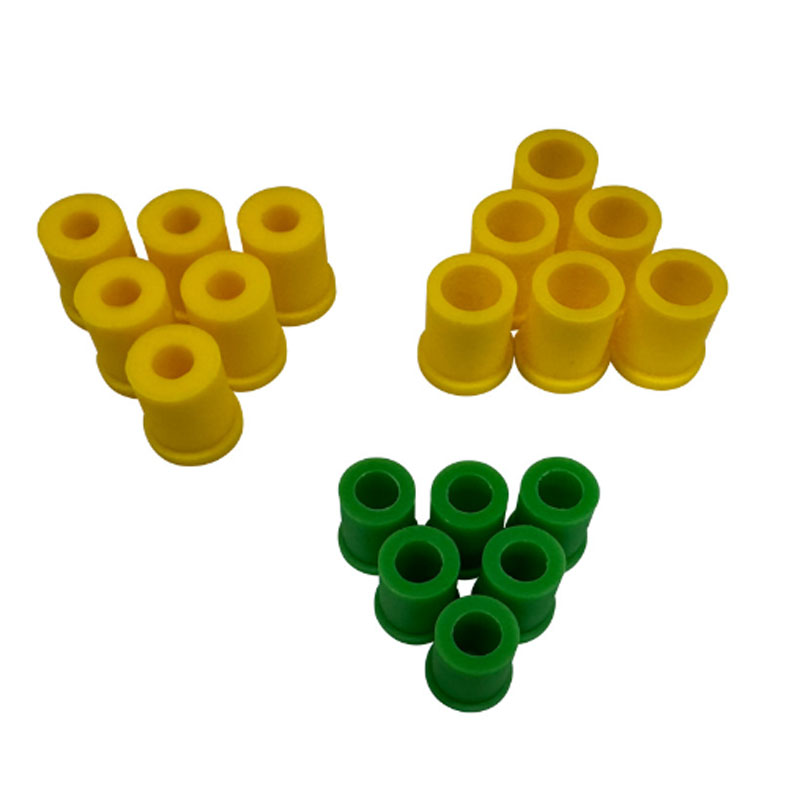

A sealed plug

Hardy plugs can be made to adapt to various sealing conditions. In use to isolate the role of the external environment and internal devices, to prevent fluid and gas leakage. The seal can be divided into two categories: static seal and dynamic UPL ...

Description

marker

Hardy plugs can be made to adapt to various sealing conditions. In use to isolate the role of the external environment and internal devices, to prevent fluid and gas leakage.

The seal can be divided into two categories: static seal and dynamic seal. Static seals of static seals mainly pillows of the seal, sealant sealant and direct contact of the seal of three categories. In accordance with the working pressure, static seals can be divided into static seals of low pressure and static seals of high pressure. Middle and low pressure static seals are usually used by materials softer width wider than seals, high pressure static seals with hard material, contact width is a very narrow metal gasket. Dynamic seals can be divided into two main types: rotating seals and reciprocating seals. Other seals and their relative parts of the movement of contact can be divided into contact seals and contactless seals; In accordance with the seals and contact positions, it can be divided into district seals and end seals, end seals are also known as mechanical seals. Dynamic seals in centrifugal seals and spiral seals, with the help of the machine, so that the medium of power, in order to get the seal, is sometimes called power seals.