Products

-

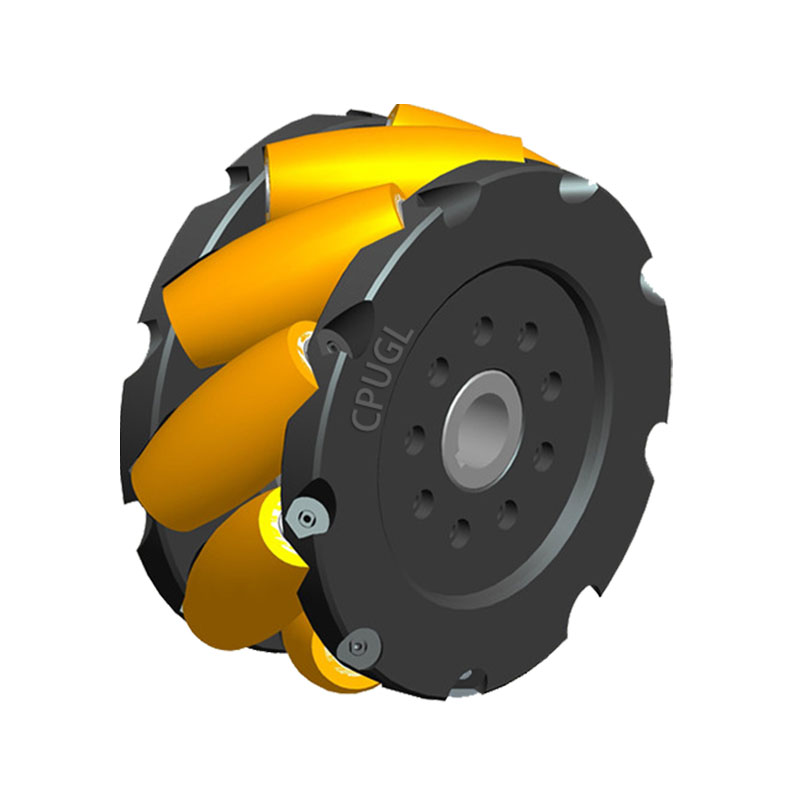

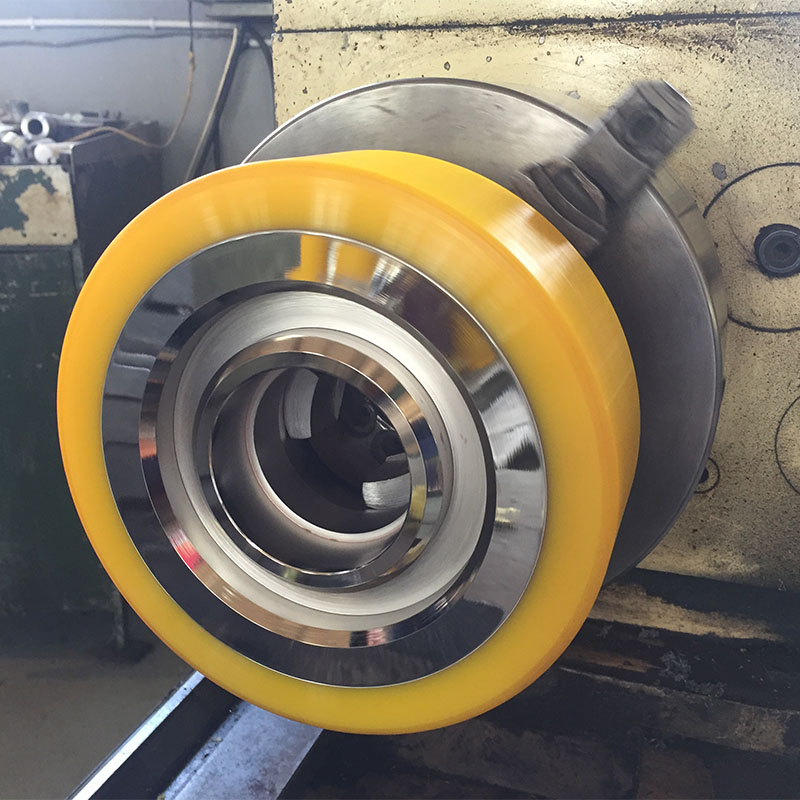

Railway transport wheel

-

Highlighting cover

-

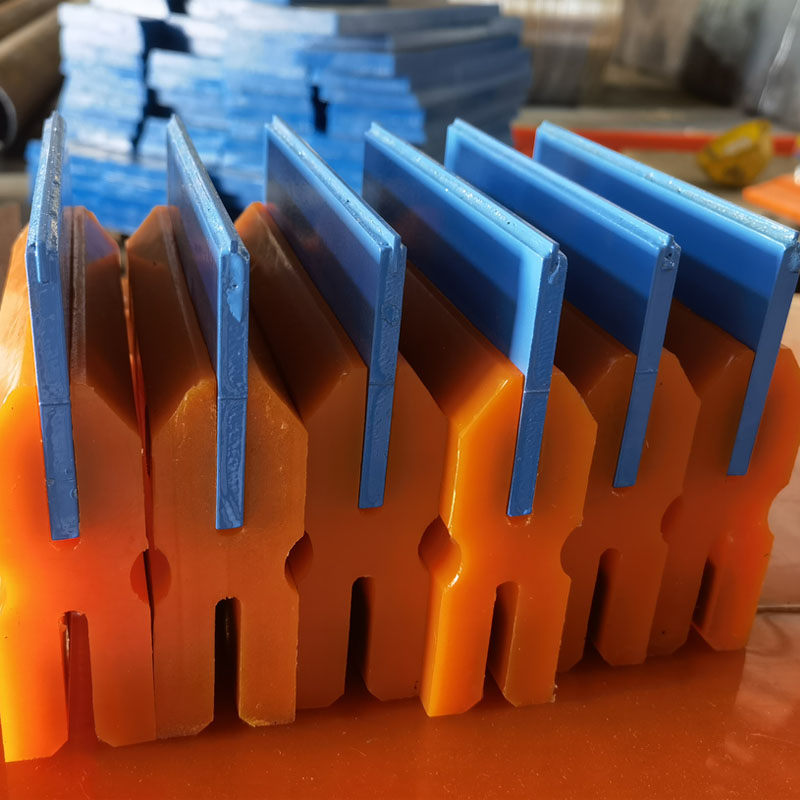

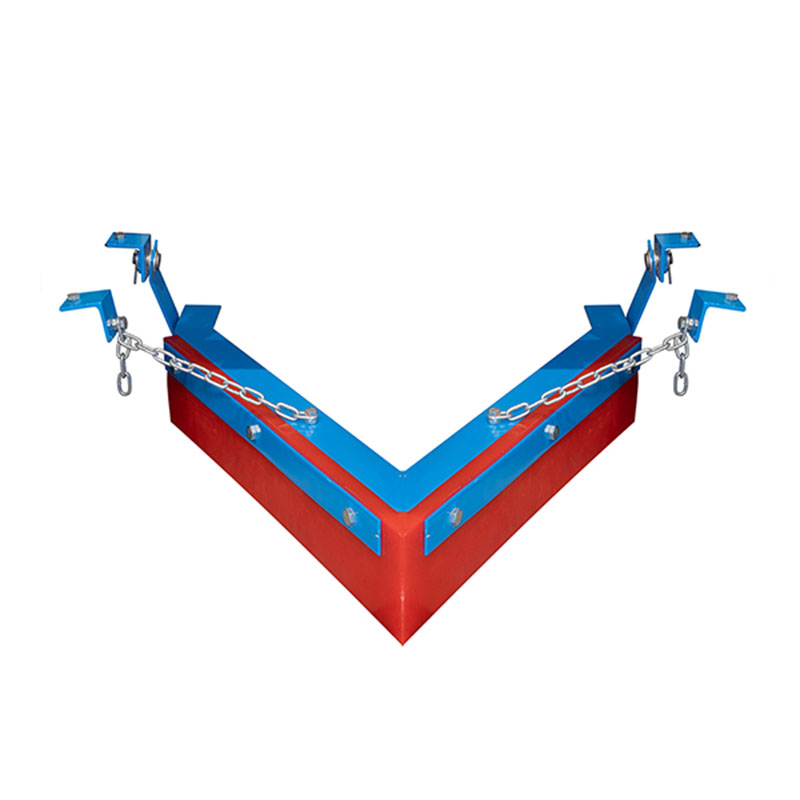

Polyurethane scraper

-

Polyurethane V-shaped video

-

Polyurethane shaped details

-

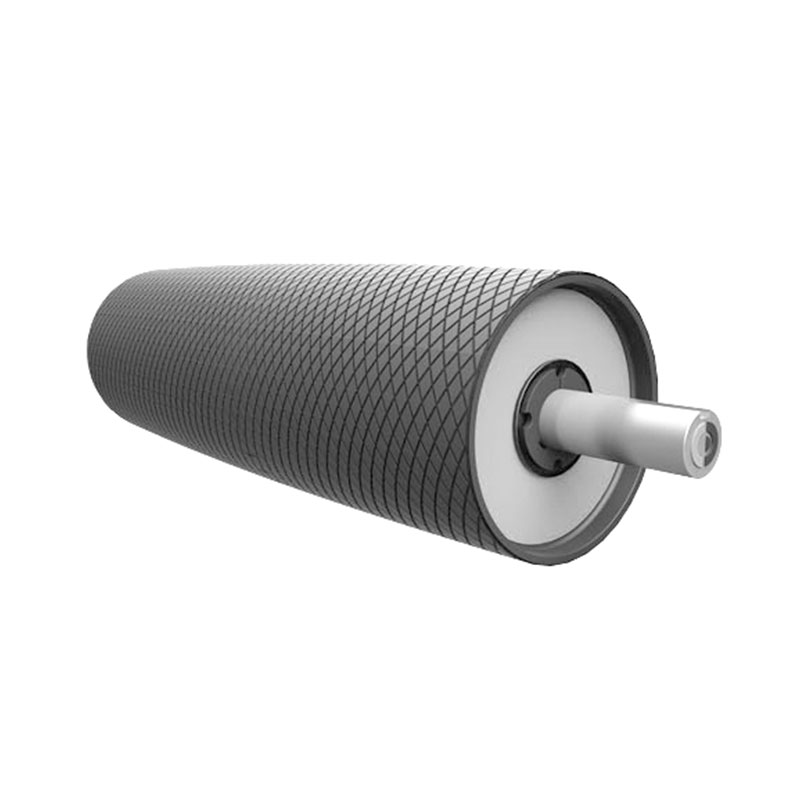

Polyurethane roller

-

Cleaner of the reverse air section

-

The video of the conveyor tape

-

Sealing tape

-

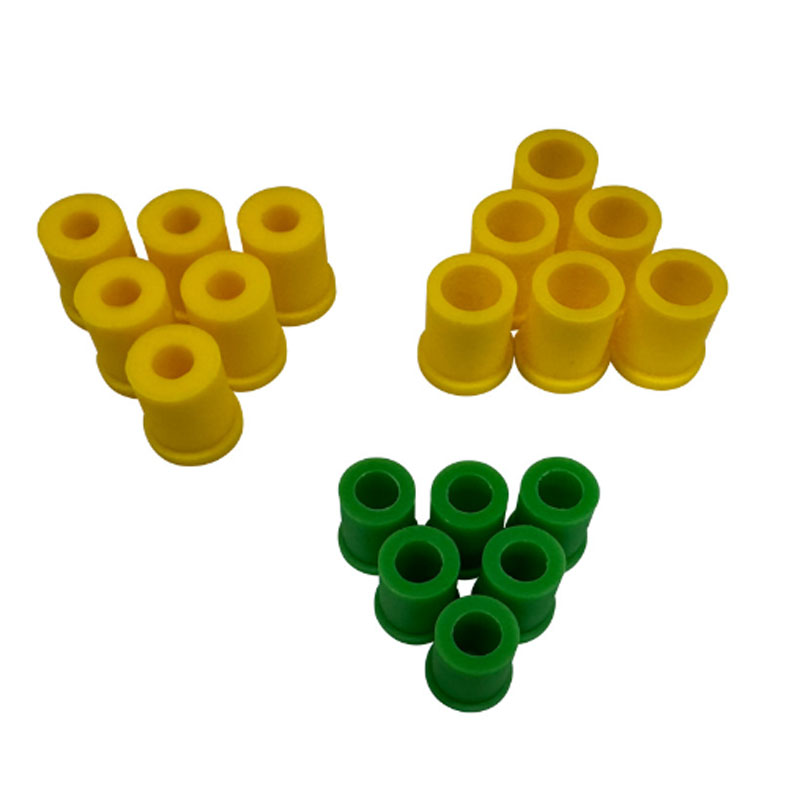

Sealing gasket

-

U-shaped seal

-

Assault seal

-

Kolesiko leg

-

Drum screen

-

Polyurethane threaded videos

-

Heavy wheel

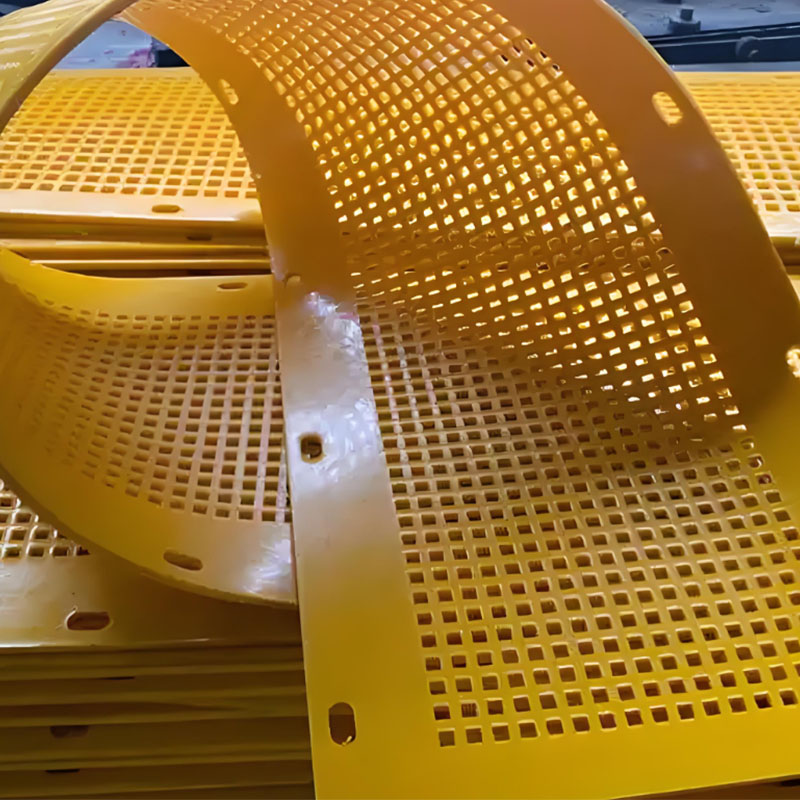

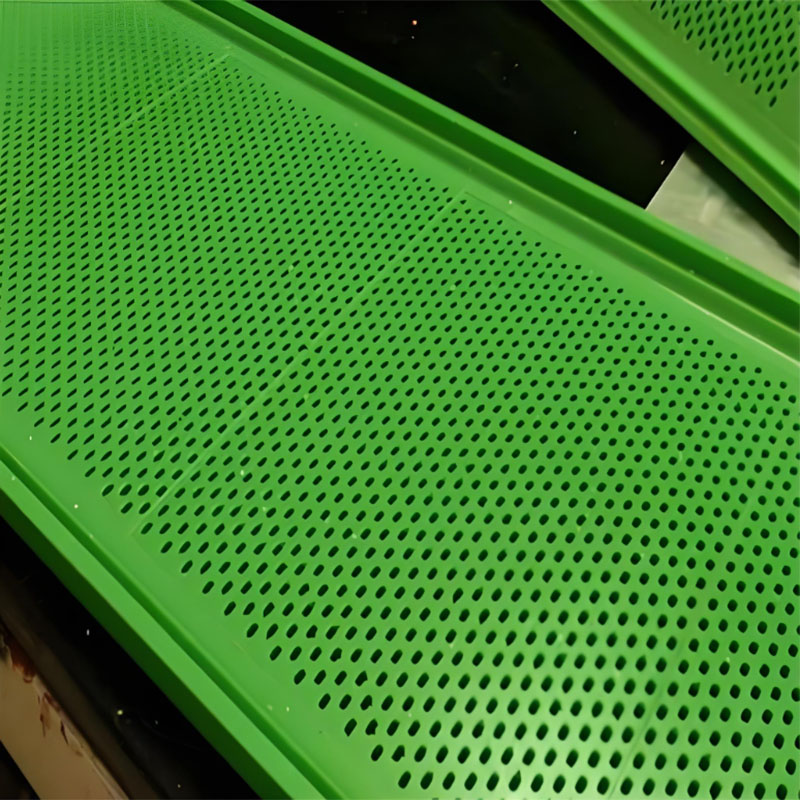

Sita for the roar of polyurethane

The relaxation screen is an enemy of sorting sticky materials. The relaxation screen is flexible, and the material of the shells is removed one by one, which helps to reduce clogging, especially when the material is sticky and humid. Moreover, the screens can be replaced separately without affecting each other ...

Description

marker

The relaxation screen is an enemy of sorting sticky materials. The relaxation screen is flexible, and the material of the shells is removed one by one, which helps to reduce clogging, especially when the material is sticky and humid. Moreover, the screens can be replaced separately, without affecting each other, which reduces costs!

| project | size |

| Screen size | Can be configured in accordance with the needs of the client |

| thickness | 1-20mm |

| The size of the hole of the sieve | 1-50mm |

| The hardness of the screen | 50a-80a |

We offer various types of chijan networks to facilitate their use in various industrial and mining conditions.

Some typical applications

Enrichment of iron ore with a thickness of 6 mm and a moisture content of 15 %.

Unprocessed sand 3 mm thick and 6 %humidity.

Compost 10 mm thick and 50%humidity.

Slag of powder metallurgy with a thickness of 3 mm and a moisture content of 10%

Salt 3 mm Humidity 5%

Sorting quasicox 3 mm thick, 20 %humidity.

6 mm, quasi, humidity 50%

Quasugar 6 mm thick containing 18% moisture.

Quasiosi -reckoner 3 mm thick and 20 %humidity.

Quasicox 3 mm, humidity 18%.

High effectiveness of screening. The sieve surface has self -cleaning properties, does not block holes and has high sifting efficiency. Due to the high water permeability of polyurethane and the large corner of the tag of the sidelines, it can effectively prevent adhesion of moist fine -grained materials, therefore it is suitable for sifting and classifying wet fine -grained materials. For the production of polyurethane sieves, our plant uses imported raw materials, and its elastomer and good relaxation properties allow you to effectively avoid blocking holes in dynamic conditions.