Products

-

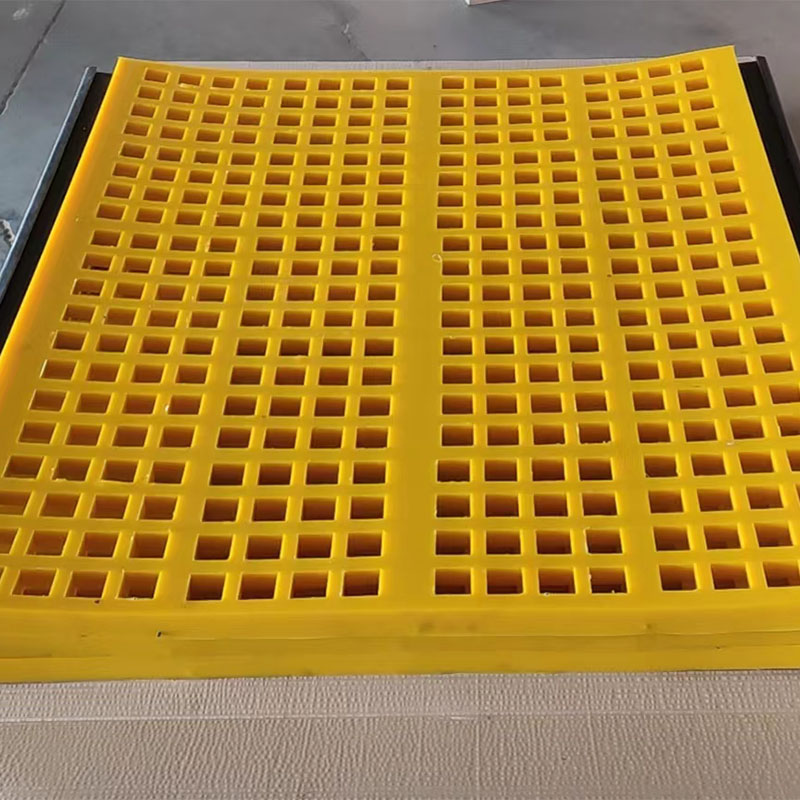

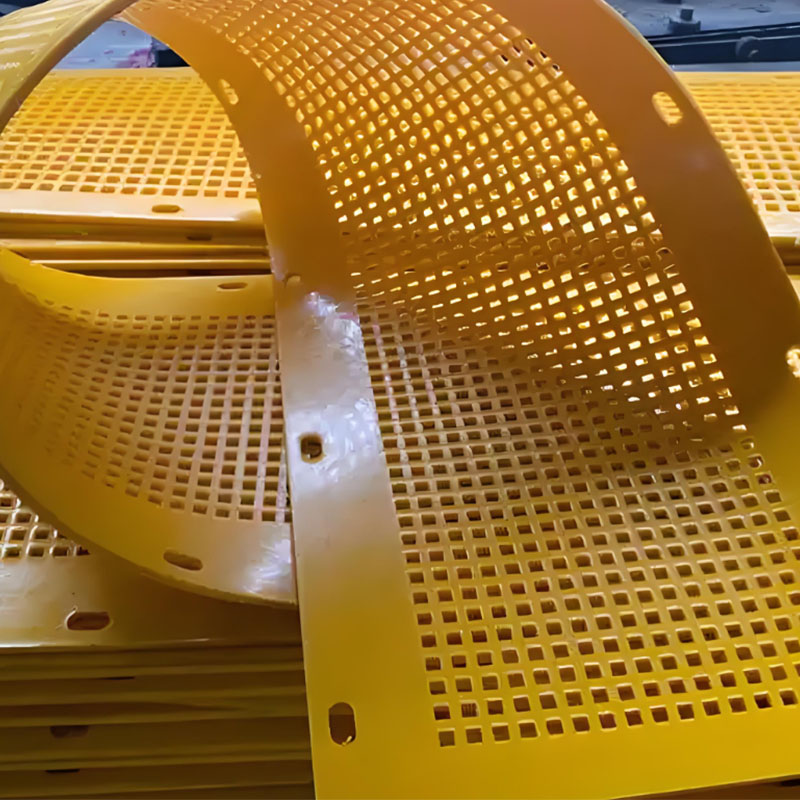

Sita mesh with tension

-

Polyurethane V-shaped video

-

Polyurethane lining pipes

-

Sita for the roar of polyurethane

-

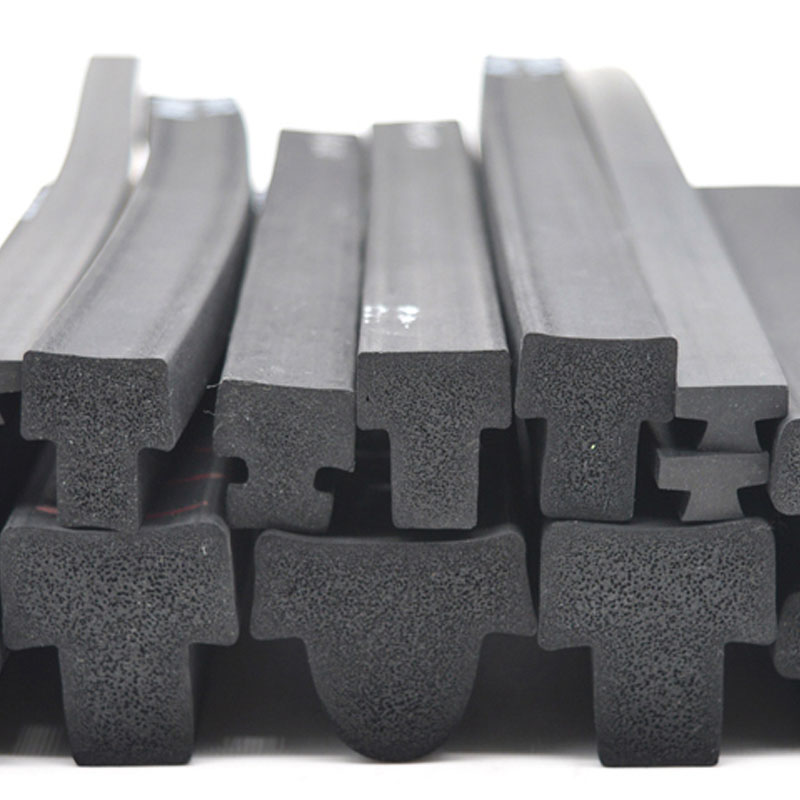

Sealing tape

-

Polyurethane vibration gaskets

-

Polyurethane buffer

-

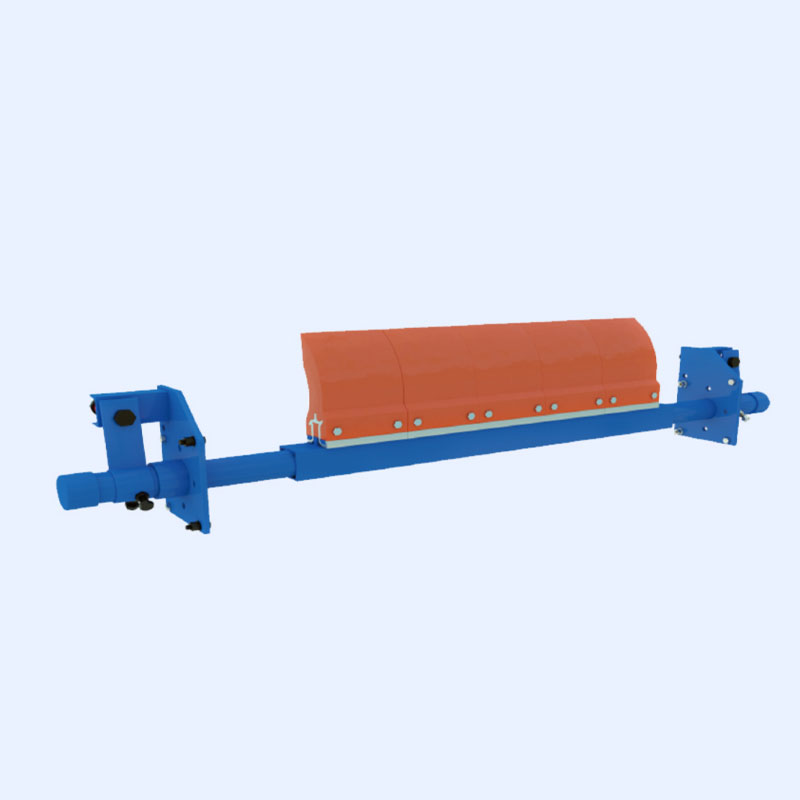

The video of the conveyor tape

-

C-shaped seal

-

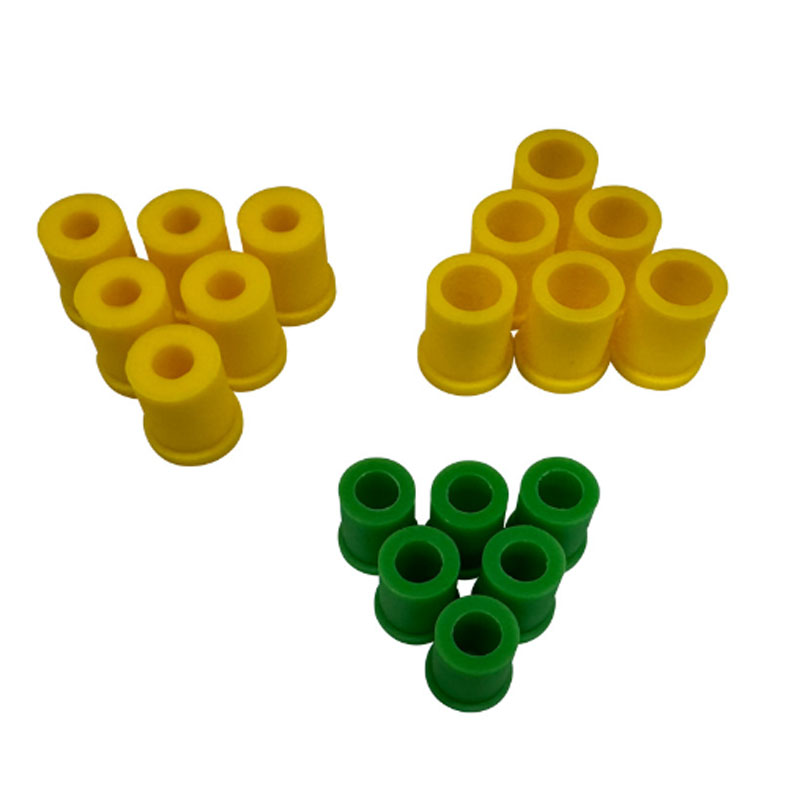

Sealing ring

-

Polyurethane wear -resistant liner

-

Kolesiko leg

-

Y-shaped seal

-

Highlighting cover

-

Polyurethane Otteral machine

-

Polyurethane springs

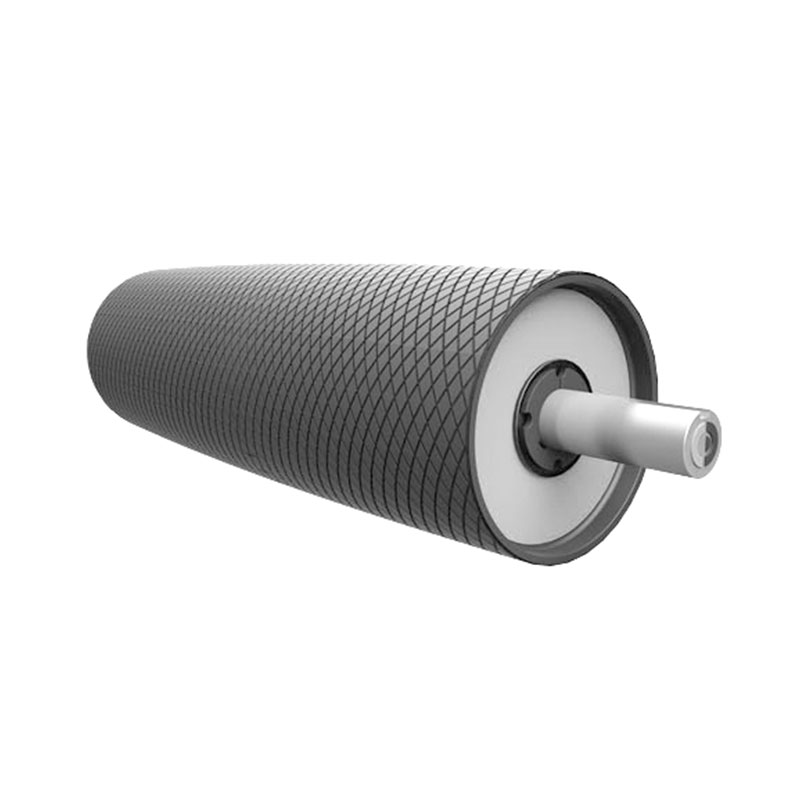

Polyurethane threaded videos

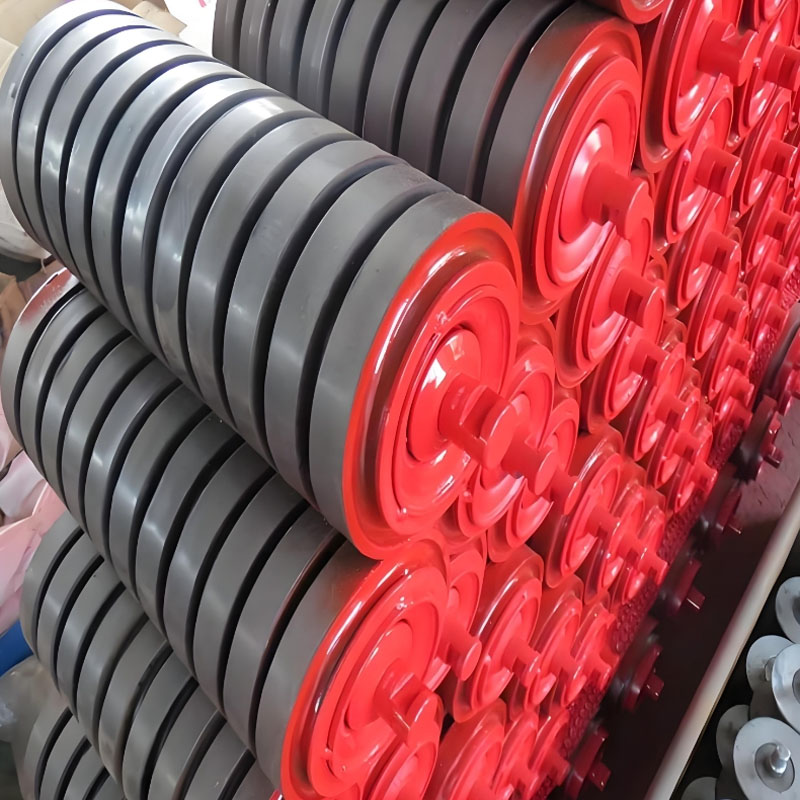

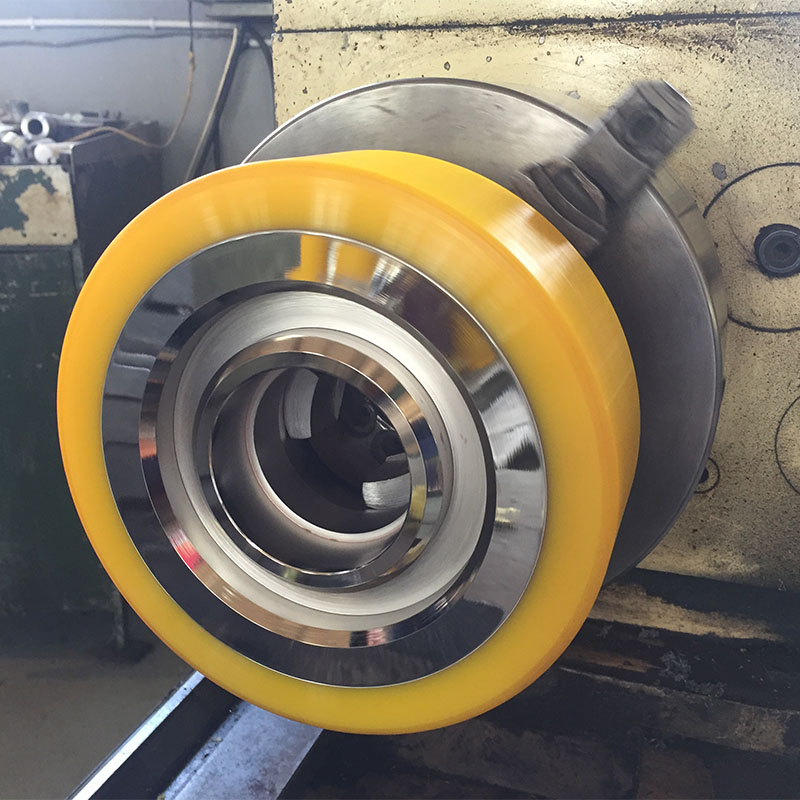

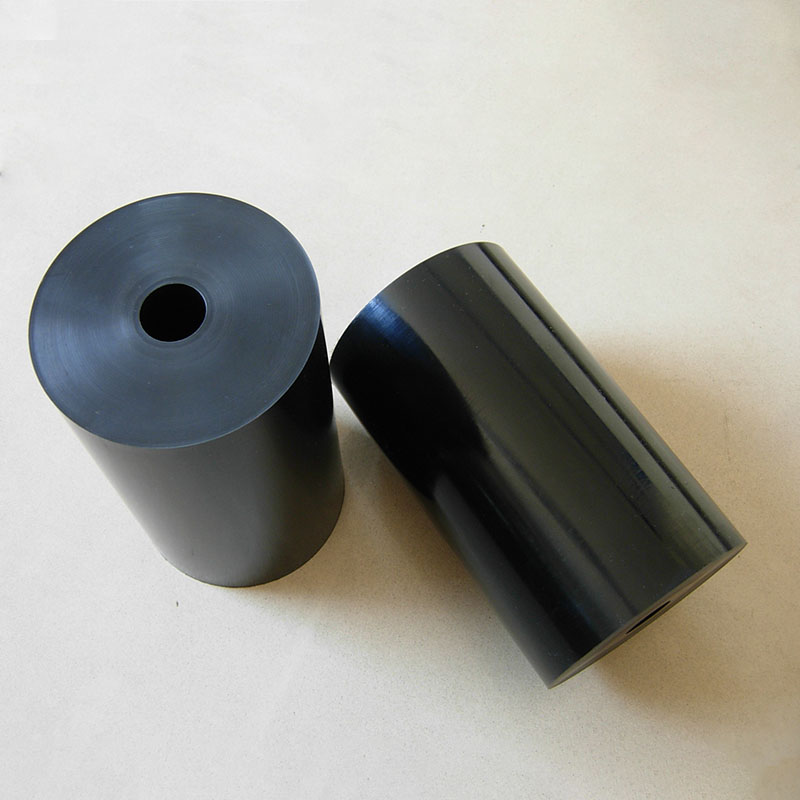

The range of counterweights for polyurethane rollers. The elasticity and elasticity of vulcanized rubber, despite high hardness. Polyurethane elastomers have a range of strength A10-D80 in Shore A. The high compression strength. Their strength for stretching, compression strength at ...

Description

marker

The range of counterweights for polyurethane rollers. The elasticity and elasticity of vulcanized rubber, despite high hardness. Polyurethane elastomers have a range of strength A10-D80 in Shore A. The high compression strength. Their strength of compression at stretching, compression strength during rupture and fatigue strength is much higher than that of the vulcanized general purpose of general purpose with the opposite strength of vulcanized rubber. With high hardness, its shock strength for compression and compression strength during bending is much higher than that of plastic. Polyurethane rollers are anti-symbolic, their corrosion resistance is excellent, as a rule, in the range of 0.02-0.10 (cm3)/1.61 km, about 3-5 times more than in volcanic rubber.

Spiral videos are used to clean the material adhering to the supporting surface of the conveyor tape, and their role is the same as the role of the cleaner, usually a group of lower rollers closest to the head of the conveyor, is made in the form of spiral rollers, which serve to support the weight of the conveyor tape and material. The work of the rollers should be flexible and reliable. A decrease in friction between the conveyor tape and the roller plays a key role in the service life of the conveyor tape, which accounts for more than 25 % of the total cost of the conveyor.